Description

Designed for the safe and automated discharge of bulk bags, the EasyFlow EF500 OEB is specifically engineered for handling sensitive powders in confined spaces.

The EasyFlow EF500 OEB bulk bag emptying station by Palamatic Process offers an advanced automated solution for unloading powdered and granular products, ensuring a high level of containment to protect operators.

Optimized Safety and Ergonomics in Confined Spaces

Specifically designed to meet the demands of industrial environments requiring strict dust emission control, this station ensures efficient emptying while adhering to OEB (Occupational Exposure Band) standards. It is ideal for the pharmaceutical, chemical, and food industries, where safety and quality in material handling are critical

-

Containment4

-

Containment5

-

Hygiene4

Benefits of the EasyFlow EF500 OEB Station

Secure Containment

The containment design of the EasyFlow EF500 OEB station is engineered to minimize operator exposure to potentially hazardous dust. This model complies with OEB3 and OEB4 containment standards, ensuring maximum protection with robust sealing systems, airtight gaskets, and dust capture technologies. These features safeguard personnel and ensure contamination-free material handling.

Ergonomics and Efficiency

The EasyFlow EF500 OEB station enhances operator comfort with tailored lifting systems and intuitive controls. It is also designed for easy cleaning, reducing the risk of cross-contamination. These features help minimize downtime and improve productivity while meeting the specific demands of various industries.

Versatility of Use

The EasyFlow EF500 OEB station accommodates a wide range of super sack types and sizes, offering exceptional flexibility. This model can handle sensitive products and fine powders, making it suitable for numerous industries. Optional liner-cutting devices can also be integrated to facilitate the handling of lined bags, commonly used in the pharmaceutical sector.

How the EasyFlow EF500 OEB Station Works

Steps for Bulk Bag Emptying

The emptying process with the EasyFlow EF500 OEB station involves simple and secure steps:

- Positioning: The bulk bag is placed on the station using lifting systems. The support structure keeps the bag upright for optimal unloading.

- Opening the Bag: A secure opening is performed, allowing controlled flow of powders without releasing dust into the environment

- Unloading: Powders are smoothly and securely discharged into production equipment.

Containment Technologies

Integrated containment technologies, such as airtight gloves, sealing gaskets, and dust capture systems, ensure a confined environment throughout the emptying process. These features reduce the risk of fine particle dispersion in the workspace, guaranteeing enhanced safety.

Equipment advantages

- Secure Containment

- Ergonomics and Efficiency

- Versatility of Use

Media

View our equipment in videos

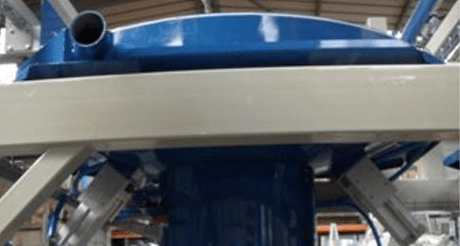

Gripping by hydraulic clamp - EF500

View our equipment in photos

100% automated gripper

The hydraulic gripper for bulk bag emptying is 100% automated.

Hydraulic emptying clamp with 2 synchronized arms

Automatic handling of bulk bags, such as big bags, by the automatic gripper for delivery to the cracking hopper, ensuring optimized decompaction and emptying.

Bulk bag breaker

The bulk bag piercing tip enables unloading without human intervention (100% automated).

Features

Industrial Applications of the EasyFlow EF500 OEB Station

The EasyFlow EF500 OEB station is utilized in various industrial sectors:

- Pharmaceutical Industry: Secure unloading of Active Pharmaceutical Ingredients (API) with strict containment.

- Chemical Industry: Emptying of chemicals and toxic substances requiring a high level of containment.

- Food Industry: Handling of sensitive powders where dust control is essential to maintain product quality.

Each sector demands reliable solutions to handle potentially hazardous materials while protecting operators from health risks. The EasyFlow EF500 OEB perfectly meets these requirements.

Spécifications

| Feature | Details |

|---|---|

| Capacity | 1 to 25 bulk bags/hour |

| Materials | Painted steel, 304L stainless steel, 316L stainless steel |

| Finishes | RAL 9006, bead-blasted, electropolished |

| Energy Requirements |

- Pneumatic 6 bar - Hydraulic - Electrical 400 V - 50Hz - 5 to 10 kW |

| Equipment Dimensions | Adaptable based on configuration |

| Dust Extraction Capacity | 2,000 m³/h (optional) |

| Max Bulk Bag Dimensions | 1,100 x 1,100 x 1,200 mm |

| Lifting Capacity | 1,500 kg |

| Bag Handling | Hydraulic clamp with two synchronized arms |

| Load Capacity | Up to 1,500 kg |

| Containment Standards | OEB3 to OEB4 |

| Accessories | Cutting systems, dust extraction systems |

These specifications ensure that the equipment complies with the strict standards of industries prioritizing safety and quality.

Options and Accessories for the EasyFlow EF500 OEB Station

Safety Accessories

Additional safety options can be integrated into the EasyFlow EF500 OEB station to enhance security, including:

- Integrated gloves for contact-free handling.

- Safety locking systems.

- Isolation hoods to further protect operators from exposure to powders.

Adaptation Accessories

The station can be equipped with various discharge spouts to accommodate different bulk bag formats. Additionally, a dust extraction system can be added to ensure a clean workspace and reduce the risk of inhaling fine particles.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Contained feeding of pharmaceutical ingredients

Processed material: titanium dioxide - Contained feeding of pharmaceutical ingredients - Bulk bag discharge by vacuum pipe for the contained feeding of pharmaceutical ingredients.Fine chemical

Cement unloading and conveying

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton bulk bags with pneumatic transfer of material to silo storageMinerals and building

Unloading and filling of KDLNO bulk bags

Processed powder: lithium nickel potassium oxide - Unloading, filling of big bags and transfer of material - The objective of this installation is to protect the operators with equipment designed to...Energy

High-rate bulk bag unloading system for the plastics and polymer industry

Processed powders: PET resin granules and PET flakes - Fully automated big bag discharging line - Big bag compaction at the end of the lineInsect breeding

Quartz production process

Processed powder: Quartz - Quartz production process - A customized solution to automate the unloading of bulk bags for a world leader in the production of high-purity quartz.Energy

Nickel hydroxide production process

Processed powder: nickel sulfate - Tailor-made solution to increase nickel hydroxide production in response to growing demand for electric vehicle batteries.Energy