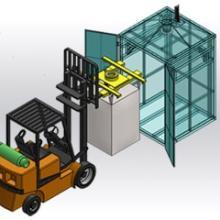

Processed material: titanium dioxide

Confined unloading of pharmaceutical products

Functions of the installation:

- Emptying bulk bags from the top using a suction pipe.

- Connection to the customer's existing pneumatic transfer system.

Objective:

The customer need to empty the product using a clean and contained method, with minimal risk of cross-contamination. The EasyFlow® Flex equipment represents the best solution for emptying the FIBC by vacuum conveying from above the super sack. There are several advantages to this setup:

- Minimal parts in contact with the product (only one suction wand)

- Dust free discharge operation due to the vacuuming of material from above the bag instead of by gravity below

- Possible change of the bulk bag mid-discharge with easy re-sealing of the sleeve (easy to change bags and products without full empty required)

Further design advantages are the mobility of the system, total containment and design of the connection head which is completely and easily removable via a sliding lock.

The bulk bag is emptied via an EasyFlow® Flex station in a confined manner and specifically adapted to the field of powdered products.

Loading and positioning of the super sack on the structure is done by means of the quick hooks design. This allows fast positioning and removal of the bulk bag.

An inflation fan ensures the shaping of the bulk bag to prevent folds during emptying.

A cylinder massage system improves the emptying rate and efficiency by funneling the material to the center of the bulk bag.

The vacuum wand allows the product to be pneumatically conveyed out of the bulk bag and moved through the pneumatic transfer circuit. The vacuum wand can be dismantled by a quick clamp and has a stroke of 1,200mm.

An electric control box with touch screen PLC on the equipment allows the piloting of the line.

The advantages of "Machine safety":

- External polycarbonate side guard panels

- Rear facing to the wall

- Light curtain with protective cover on front panel