Description

PADDLE MIXER - DISCONTINUOUS - FAST, HOMOGENEOUS MIXING

Mixing and homogenization of several materials (successive batches)

The BRP double shaft mixer is a continuous mixer with two parallel tanks, each fitted with paddles which promote a homogeneous mixing regardless of the particle size and density.

The intensive mixing action, even with delicate or friable materials, provides optimal blending while avoiding particle attrition. The paddle mixer can be started under a full load.

-

Complexity of mixtures5

-

Rate4

-

Hygiene3

Equipment advantages

- Fast discharge time due to double discharge outlets

- Short mixing time (5-30 sec.)

- Easy cleaning

- Maximum homogeneity of materials

- Gentle mixing action for delicate and friable materials

- Low residue (0% - 5% of the volume)

Media

View our equipment in photos

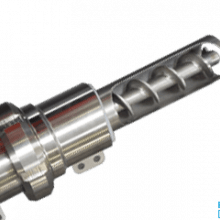

Birotor paddle mixer

Mixer on a process line for mixing and packing resinous materials.

Birotor paddle industrial mixer

The double blade shaft mixers are fitted with two reverse rotating rotors with secant blades.

Raw ingredients mixing

Industrial mixer with pallets on an industrial production line.

Bulk materials industrial mixing

Industrial production line for cake recipes.

Features

Technical specification

Capacity: 48 to 5,000 liters

Objectives: homogenization and mixing of materials with different characteristics

- Coefficient of variation reached (CV): less than 3%

- Mixing ratio: 1/100,000

- High homogeneity (CV < 5%)

- Bearing end with rotor sealing group in various versions with optional air or gas pressurization

- Double bomb bay discharge

- Robust mixing tank made of carbon steel or 304 L stainless steel

Dimensions

| Models | BRP-120 | BRP-250 | BRP-500 | BRP-1000 | BRP-2000 |

|---|---|---|---|---|---|

| C | 1,484 | 1,784 | 2,269 | 2,690 | 3,170 |

| D | 1,059 | 1,363 | 1,835 | 2,170 | 2,662 |

| E | 1,004 | 1,104 | 1,620 | 2,036 | 2,373 |

| NOMINAL VOLUME IN LITERS | 120 | 250 | 500 | 1,000 | 2,000 |

| MIN. OPERATING CAPACITY IN LITERS | 48 | 100 | 200 | 400 | 800 |

| MAX. OPERATING CAPACITY IN LITERS | 168 | 350 | 700 | 1,400 | 2,800 |

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Manufacture of aperitif biscuits

Processed powders: pumpkin seeds, linseed, sesame seeds, corn starch - New installation for the manufacture of biscuits and crackers - Emptying of big bags to feed a mixerFood and Animal Feed