Octabins are rigid cardboard containers designed for storing and transporting dry materials in pellet or powder form, ensuring smooth flow. They are primarily used by professionals in the chemical, petrochemical, plastics, pharmaceutical, and nuclear industries, allowing for optimized logistics while providing effective product protection.

However, several challenges remain: ensuring a smooth discharge without residue, minimizing risks for operators, and integrating the discharge process into existing production systems.This article explores various technical solutions to ensure efficient and safe octabin emptying.

1. Octabin: An optimized container for industrial powders and pellets

It is designed to store plastic pellets, chemical additives, resins, catalysts and pharmaceutical powders. These materials have low hygroscopicity and good flow, which facilitates their use in industry.

Its main advantage is its rigidity and stackability, thus optimizing storage and logistics. In addition, it offers protection against moisture and contamination and is a more economical and recyclable solution than metal drums. These advantages make it a preferred choice for sectors such as chemicals, plastics, pharmaceuticals (in particular containers) and even nuclear power.

2. Challenges of emptying an octabin in an industrial setting

2.1 Common issues during emptying

Residue accumulation in the corners can lead to material loss and complicate equipment cleaning.

Poor product flow can slow down production processes and require manual intervention. For finer pellets, improper connections may cause dust dispersion, posing safety and hygiene risks.

2.2 Risks for operators and production

Manual handling exposes operators to musculoskeletal disorders (MSDs), especially during repetitive movements or prolonged effort when handling bags or bulk bags. Additionally, poor flow management can lead to leaks and increase the risk of cross-contamination between different materials.

3. Discharge methods and their performance

3.1 Tilt discharge

Emptying the tank by tilting it is certainly the simplest and least expensive solution. However, it requires the addition of a pneumatic transfer system by suction (suction rod) and, depending on the flow of the product, the action of the operator to move the rod in the octabin.

The use of an automated tipper facilitates the handling of heavy loads and guarantees fast and efficient flow. This method is ideal for industries requiring a high level of safety and precision, such as the nuclear or pharmaceutical industries.

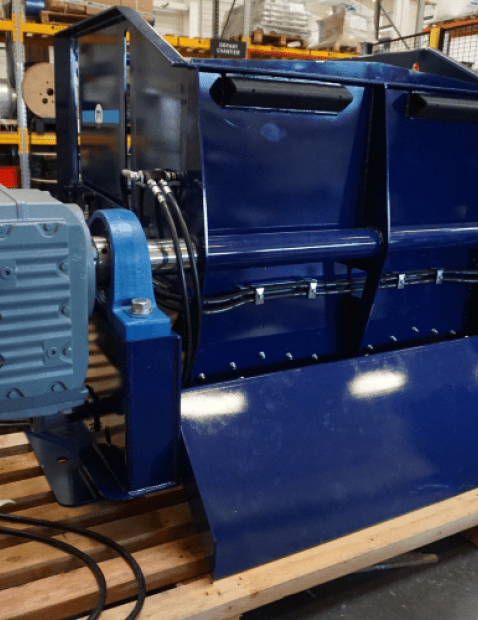

3.2 Tipping discharge

This method consists of gradually tilting it using an assisted system. It allows for the efficient flow of pellets and low-volatility powders.

Its main advantages:

- Extraction of the product without the need for additional equipment.

- Optimized flow rate (100% for pellets).

Its disadvantages:

- Requires height in the installation area.

Fine and dusty products should be avoided.

3.3 Inversion discharge

The use of an automated tipper facilitates the handling of heavy loads and guarantees a fast, total and secure flow (cross-contamination).

This method is suitable for:

- Products with poor flow and fine particle sizes.

- Processes with multiple raw materials. It avoids any cross-contamination since it is emptied into a dedicated container.

- Traceability and coding: dedicated container for each powder.

This solution requires a more substantial investment in return for the purchase of a fleet of hoppers dedicated to each octabins.

3.4 Pneumatic suction discharge

Used for fine powders and chemical or pharmaceutical products, this technique ensures a smooth, safe and contained transfer. Thanks to a means of enclosure, it reduces operator exposure and prevents the dispersion of particles.

It can be adapted to any type of octabin: with or without an inner bag. Like the octabin tilt mechanism, it requires connection to a pneumatic transfer system.

3.5 Vibration-assisted discharge (complementary solution)

Adding vibrations to the base of the octabin tipper and dumper improves the flow of products that can form arches or preferential channels. This solution is particularly suitable for materials with a slight cohesion and ensures a regular flow to downstream equipment.

Do you have a project?

I am available to advise you and support you in your study.

Loïc, expert in powder containment

4. Industrial solutions for optimal octabin discharge

4.1 Automation: A key factor

This automation makes it possible to improve productivity by reducing manual interventions. Motorized turners, the suction system and the tipper (for free-flowing materials) are particularly suitable for this purpose.

To a lesser extent, the incliner for free-flowing products also helps to achieve this objective.

4.2 Safety and enclosure

In the case of powdered products with a smaller particle size, the installation of airtight connections to the transfer systems prevents any leakage of material. This is found on the turning and suction solution.

In addition, the suction of residual dust helps to maintain a clean and safe working environment, which is particularly important for regulated sectors.

4.3 Integration with production equipment

Several additional pieces of equipment can be added to the station connected to the pneumatic transfer system (turner, incliner, Octoflex).

The in-line screens integrated into the pneumatic transfer systems guarantee effective separation of impurities, thus improving the quality of the final product.

In addition, the dosing systems at the outlet of the suction cyclofilters allow precise control of the material flow, thus optimizing the entire industrial process.

5. Q&A: Everything you need to know about octabin discharge

What equipment should I choose to empty it?

The choice of equipment depends on the type of material to be handled. The tipper and the incliner are suitable for pellets or powder with good flow.

The turner and the OctoFlex system will be particularly suitable for fine powders with poor flow and requiring enclosure.

How can I avoid residue in the octabins?

The use of tilting turners, hopper vibrators or controlled suction systems ensures complete emptying without loss of material.

Which systems are suitable for sensitive materials?

Industries that handle sensitive materials, such as the pharmaceutical and nuclear industries, favor contained drainage systems.

The OctoFlex system with suction rod is particularly suitable for this purpose. This requires that the raw material be packaged with an additional inner bag.

Is emptying an octabin compatible with the enclosure requirements?

Yes, specific solutions exist to ensure contained discharge, particularly in sectors requiring enhanced protection against dust emissions (CMR, toxic and aggressive powder). Airtight suction systems, combined with automated emptying stations, make it possible to comply with the strictest standards in terms of enclosure.

Conclusion

The octabin emptying solutions offered by Palamatic Process must combine simplicity, ergonomics and flexibility to adapt to industrial constraints. Optimizing these systems not only makes the handling of raw materials safer, but also improves packaging management and transport. By reducing losses and automating operations, companies benefit from increased productivity and logistical efficiency.

Contact our experts for a personalized study and discover the solutions adapted to your sector!