Surely you have heard of AdBlue when you had to refuel. Do you know what it is? This liquid is marketed by Total Energy Services and has become essential for Diesel vehicles. In this article you will learn what AdBlue is used for and how it is made.

1. What is AdBlue?

The AdBlue system appeared in 2015 to meet the EURO 6 standard. The Euro 6 standard imposes a reduction in NOx levels at the exhaust of diesel vehicles. Systems requiring AdBlue have become generic on diesel vehicles since 2017 and has since been fitted to most current diesel engines.

AdBlue is now a common product, marketed in Total service stations and can also be found at auto centers. AdBlue comes in the form of jerry cans or directly at the pump.

2. What is the composition of AdBlue?

AdBlue is an aqueous solution with a mass concentration of 32.5% urea. In order to produce 1 ton of product, the AdBlue production line must introduce 325 kg of urea for 675 kg of demineralized water. For a better-quality product, the water must be as pure as possible. Therefore, the AdBlue process requires the water to be thoroughly treated, ensuring it is free from impurities. This criterion is measured by carrying out conductivity tests: the less the water is loaded with minerals, the less conductive it is. When the water has been heated and purified, the urea can be introduced and stirred to provide homogeneity of the solution.

The production line mixes AdBlue which can be stored in a tank or directly in cans, drums, IBCs or even tanker trucks, depending on the associated logistical needs.

The use of off-specification water in the production of AdBlue is probably the biggest threat to your catalyst and your vehicle. It is essential to buy from a supplier who produces AdBlue according to the global ISO specification.

You want to manufacture AdBlue? I can

assist you in setting up your process.

Tarik, powder expert

3. Who produces AdBlue?

The main producers of AdBlue are TotalEnergies, GreenChem, Yara or Brenntag. It is also possible for a small company to produce AdBlue on its own due to the simplicity of the manufacturing process.

There are also many retailers who redistribute AdBlue in different formats: in cans, jerry cans or at the pump.

The packaging of AdBlue does not affect its quality. AdBlue is also known by several names: DEF, DeNOx.

4. What are the manufacturing requirements?

The AdBlue® registered trademark belonging to the German Association of the Automotive Industry (VDA), must meet a specific standard: ISO 22241. This guaratees the product complies with the DIN 70070 standard. This standard sets the limit for urea levels but also the maximum thresholds of mineral impurities not to be exceeded, in order to deserve the AdBlue designation.

Compliance with these standards is monitored by the European Union and the VDA. They are demanding out of necessity to produce this liquid in an industrial and non-artisanal way to ensure its conformity.

5. Are there variations?

In regards to the urea solutions used in the treatment of industrial fumes, they may depart from the ISO 22241 standard by presenting a higher concentration of urea, sometimes going up to 35 or even 40% of the mass.

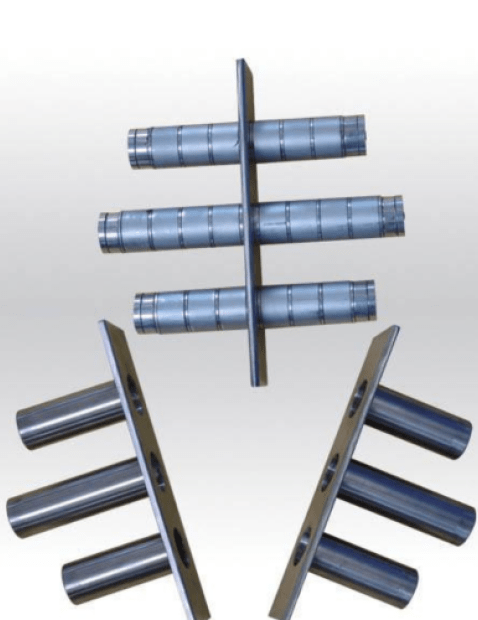

Palamatic Process has developed turnkey AdBlue production process lines: PalBlue® Skid and PalBlue® Process.