Introduction

The Inflatek valve, also known as an inflatable seal valve, is a reference solution for the precise management of powder and bulk material flow. Designed for industries such as energy, food processing, chemicals, minerals, and construction, it features an inflatable sealing system that ensures optimal tightness and a leak-free seal. Unlike traditional valves, the Inflatek valve ensures total containment of the materials being processed, reducing the risk of contamination and dust dispersion.

Its robust construction and long-lasting design make it a strategic choice for manufacturers seeking to optimize production while meeting safety and environmental standards. This article explores the features, advantages, and applications of the Inflatek valve, outlining key criteria for successful integration in your process lines.

Pour en savoir plus sur le fonctionnement, vous pouvez consulter cette vidéo explicative :

1. What is an Inflatek valve and how does it work ?

1.1 Definition and Operating Principle

The Inflatek valve is an innovative solution for controlling the flow of powders and bulk materials, engineered to deliver unmatched sealing performance and minimize product loss. Unlike traditional valves, it features a mobile cap that, when actuated by an inflatable seal, applies uniform pressure across the product path, ensuring a leak-proof seal.

Its high-performance inflatable seal eliminates excessive contact points, reducing mechanical wear and extending the equipment’s life. This design also improves handling and simplifies maintenance, ideal for demanding industrial applications.

1.2 Key Components of the Inflatek Valve

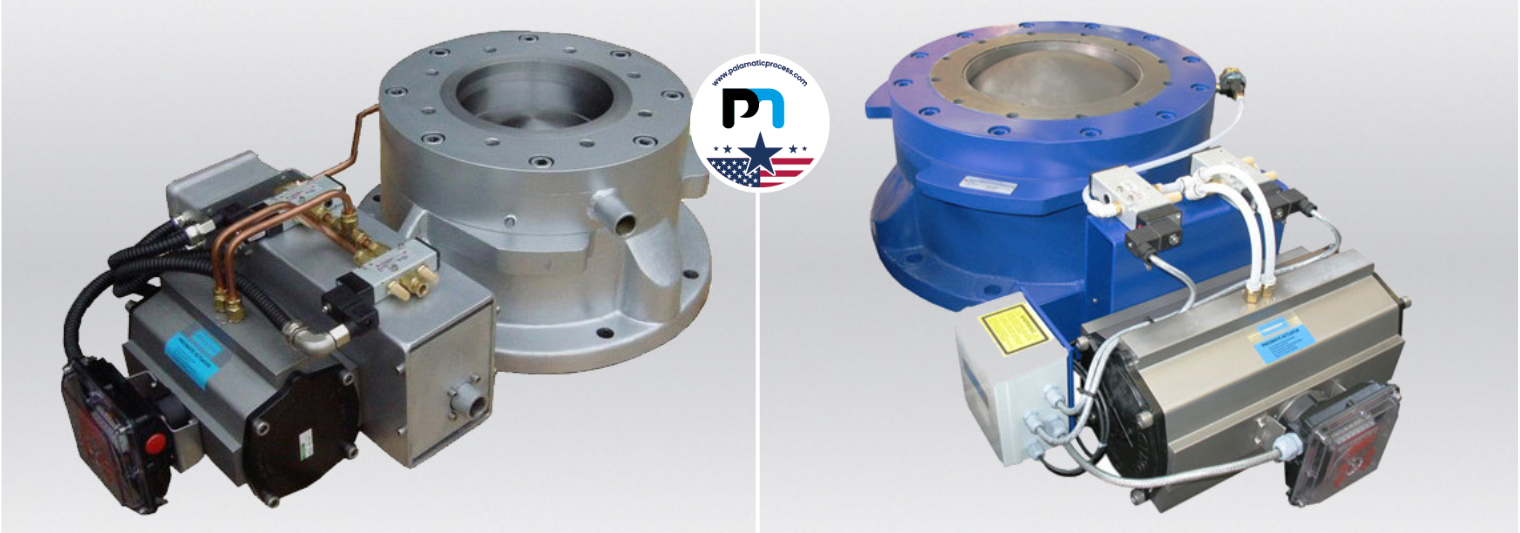

- Valve body: constructed from stainless steel for maximum corrosion and abrasion resistance in harsh environments.

- Movable cap: essential for effectively closing the product flow and ensuring proper containment.

- Inflatable seal: precisely inflates and deflates to ensure a perfect seal while maintaining material integrity.

- Pneumatic actuator: provides automated and accurate control of the opening and closing cycle, minimizing manual intervention.

1.3 Why Choose an Inflatek Valve?

- Exceptional sealing: complete leak prevention for a safe and clean environment.

- Extended durability: rugged design with high-quality materials to reduce wear and increase service life.

- Low maintenance: quick and easy seal replacement without dismantling the entire unit.

- Process compatibility: suitable for automated systems and compliant with ATEX environments and strict regulations.

2. What are the benefits of the Inflatek valve ?

2.1 Sealing and Powder Containment

- Eliminates leakage and dust dispersion, ensuring a safe and clean work environment.

- Compliant with strict environmental regulations and ATEX certification for safe operation in explosive zones.

- Enhances containment of sensitive materials, reducing the risk of cross-contamination.

2.2 Reliability and Durability

- Stainless steel construction and high-resistance materials offer protection from corrosion and wear.

- Rugged design allows for continuous use in extreme conditions.

- Equipped with a long-life inflatable seal that reduces maintenance needs and extends operational lifespan.

2.3 Versatility and Industrial Adaptability

- Compatible with a wide variety of materials, including abrasive, toxic, or moisture-sensitive powders.

- Used in the food, chemical, pharmaceutical, and mineral industries, providing a flexible solution for different environments.

- Easily integrates into automated processing lines to improve production efficiency.

3. Where and how to use an Inflatek valve in your plant ?

3.1 In Dosing and Weighing Systems

- Integrates into gravimetric and volumetric dosing systems to ensure precise raw material distribution.

- Maintains consistent dosing accuracy, reducing waste and material loss.

3.2 In Pneumatic and Mechanical Conveying Lines

- Provides optimal flow control with no blockages or product loss.

- Suitable for both positive and negative pressure systems, ideal for modern process lines.

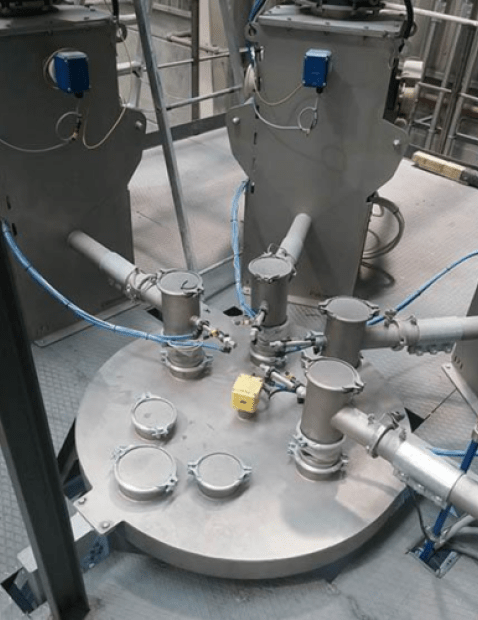

3.3 In Super Sack Filling and Unloading Systems

- Ensures complete containment during both filling and unloading operations, limiting dust exposure.

- Designed to integrate with super sack and silo systems, reducing manual handling requirements.

Working on a powder dosing or transfer project ?

I’m available to help you evaluate your needs and find the best solution.

Guillaume, expert in powder handling solutions

4. How to select the right Inflatek valve for your application ?

4.1 Key Technical Criteria

- Required diameter and flow rate based on the material and process specifications.

- Material selection adapted to the production environment (stainless steel for food, carbon steel for chemical processing, etc.).

- Operating temperature and pressure considerations to ensure full system compatibility.

4.2 Options and Configurations

- Position sensors and automation control systems for real-time monitoring.

- Manual or pneumatic actuation available to meet your operation’s needs.

- Optional integration with dosing and weighing systems for precise regulation.

4.3 Compliance with Standards and Regulations

- ATEX certification for explosive zone compliance (e.g., combustible dust, chemical industries).

- FDA and CE certifications for food and pharmaceutical applications.

- Meets current environmental regulations, helping to prevent industrial contamination.

The Inflatek valve is a key solution for achieving safe and efficient powder and bulk material flow management. With its exceptional sealing, rugged durability, and application flexibility, it is a smart investment for manufacturers seeking to optimize production and reduce material loss.

5. Frequently Asked Questions (FAQ)

5.1 What is the average service life of an Inflatek valve?

A well-maintained Inflatek valve can last for many years thanks to its robust design and high-durability inflatable seal, which reduces mechanical wear. The quality of materials used and the frequency of use are key factors. Preventive maintenance helps maximize its service life.

5.2 Is the Inflatek valve compatible with all powder types?

Yes, the Inflatek valve is designed to handle a wide range of powders, including:

- Fine powders: such as flour, sugar, and talc.

- Abrasive materials: including sand, cement, and metal oxides.

- Hygroscopic materials: such as salts, acids, and moisture-sensitive chemicals.

- Toxic and explosive substances: with configurations available for sensitive and controlled environments.

Material choice and valve options should be matched to the properties of the product being handled.

5.3 Can the Inflatek valve be used in ATEX zones?

Yes, specific Inflatek valve models are ATEX certified (zones 20, 21, 22), meaning they are safe for use in explosive atmospheres. These valves are built with anti-spark components and comply with stringent industrial safety standards.

5.4 How do you maintain an Inflatek valve to extend its service life?

Routine maintenance of the Inflatek valve ensures optimal performance. Best practices include:

- Periodic inspection of the inflatable seal to identify early wear.

- Regular cleaning of the cap and product path to prevent buildup or blockages.

- Checking actuators and position sensors to ensure proper responsiveness.

- Preventive replacement of parts to avoid unplanned downtime.

6. Conclusion

The Inflatek valve is the ideal solution to ensure tight sealing and accurate dosing in powder-handling industries.

Looking for a solution that fits your process? Contact our experts for a customized consultation!