The battery manufacturing industry is subject to a strict set of standards and regulations designed to guarantee the safety, performance and durability of batteries. These standards cover various aspects, from production and recycling to traceability and environmental impact. To meet these requirements, manufacturers use a variety of specialized machinery and equipment.

Battery production requires high-precision machinery to ensure the quality and safety of finished products.

1. European battery regulations

The European Battery Regulation is a recent initiative aimed at regulating the entire battery life cycle, from raw material extraction to collection, recycling and reuse. The regulation, which comes into force on August 17, 2023, replaces Directive 2006/66/EC and introduces several key provisions.

The battery passport

Every battery with a capacity of over 2 kWh placed on the European market will have to be electronically registered with a QR code and CE marking to ensure traceability and compliance with safety requirements.

Life cycle assessment (LCA)

The regulation requires an analysis of the carbon footprint of batteries to quantify greenhouse gas emissions throughout their value chain.

Restriction of hazardous substances

The regulation continues to restrict the use of mercury and cadmium, and introduces a restriction on lead in portable batteries.

2. The IEC standard

IEC (International Electrotechnical Commission) is an international standards organization that develops and publishes standards for electrical, electronic and related equipment. IEC standards are widely recognized and used throughout the world to ensure the safety, reliability and compatibility of electrical and electronic products.

IEC 62133

This standard sets out requirements and tests for portable and sealed batteries, with the exception of button cells. Its aim is to ensure that batteries function properly under normal, foreseeable conditions of use.

IEC 62619

Oriented towards industrial applications, this standard focuses on the risk of internal short-circuiting and includes thermal propagation tests to prevent fires.

3. ECHA (European Chemical Agency) regulations

ECHA regulation considers battery manufacturing a strategic priority for Europe, with specific requirements on environmental impact and emerging technologies.

Restriction of Hazardous Substances

Article 6 of the regulation establishes the framework for restricting hazardous substances in batteries to protect human health and the environment.

Promotion of the Circular Economy

The regulation aims to promote a circular economy by reducing environmental and social impacts throughout the battery life cycle.

4. US battery manufacturing regulations

The battery manufacturing industry in the United States is governed by a set of standards and regulations designed to guarantee the safety, performance and durability of batteries.

UL (Underwriters Laboratories) standards

UL Standards are among the most widely recognized battery safety standards in the USA. They cover various aspects of battery manufacture and use, including :

UL 1642

This standard concerns the safety of lithium-ion battery cells. It includes short-circuit, overcharge, excessive discharge and temperature tests to ensure the safety of individual cells.

UL 2054

This standard applies to batteries used in household and commercial appliances. It covers safety tests for lithium-ion battery packs, including shock, vibration and life cycle tests.

UL 2271

Standard for batteries used in light electric vehicles, such as electric scooters. It includes rigorous testing to ensure safety in the event of thermal runaway, overcharging and excessive discharge.

UL 2595

Safety standard for battery-powered appliances, covering general requirements for ensuring the safety of battery systems in various appliances.

Consumer Product Safety Commission (CPSC) standards

CPSC participates in the development of voluntary standards for batteries used in consumer products. Relevant standards include :

ANSI/CAN/UL 2272

Standard for electrical systems of personal mobility devices, such as hoverboards, to ensure electrical and thermal safety.

ANSI/NEMA C18

Safety standard for primary, secondary and lithium batteries, covering performance and safety requirements.

IEEE 1625 and IEEE 1725

Standards for rechargeable batteries used in laptops and cell phones, respectively. They include requirements for thermal management, overcharge protection and cell quality.

OSHA (Occupational Safety and Health Administration) standards

Battery manufacturing plants must comply with specific OSHA standards to ensure worker safety. These standards cover various aspects of production, including:

Chemical safety

Management of hazardous substances used in battery manufacturing, including safe handling protocols and personal protective equipment (PPE).

Worker protection

Requirements for ventilation, dust control and employee training to prevent hazardous exposure.

Environmental Protection Agency (EPA) standards

The EPA regulates effluents from battery manufacturing plants to protect the environment. Relevant guidelines include:

Battery Manufacturing Effluent Guidelines (40 CFR Part 461)

These guidelines cover direct and indirect discharges of pollutants into U.S. waters. They impose strict limits on the levels of cadmium, lead, nickel and other heavy metals in battery plant effluent.

U.S. battery manufacturing standards are designed to ensure product safety, protect workers and minimize environmental impact. UL standards, CPSC guidelines, OSHA and EPA regulations all play a crucial role in shaping the industry. Compliance with these standards is essential to ensure the compliance, safety and durability of batteries manufactured in the USA.

5. Canadian battery manufacturing regulations

The battery manufacturing industry in Canada is governed by a set of standards and regulations designed to ensure the safety, performance and durability of batteries. Here is an overview of the main standards specific to this industry:

Provincial and federal regulations

Stewardship and Extended Producer Responsibility (EPR)

Provincial regulations in Canada impose stewardship (or extended producer responsibility) obligations for batteries, particularly lead-acid batteries. These regulations require first importers of batteries to have methods for collecting end-of-life batteries. The following provinces have stewardship programs in place:

- Prince Edward Island: Stewardship and materials recycling regulations.

- Nova Scotia: Stewardship program for lead-acid batteries.

- New Brunswick: EPR regulations for batteries weighing less than 5 kg.

- Quebec: EPR regulations for sealed lead acid (SSLA) batteries under 5 kg.

- Ontario: Battery regulations.

- Manitoba: Household hazardous and prescribed materials regulations.

- British Columbia: Recycling regulations.

Battery importers must comply with these regulations to ensure proper collection and recycling of end-of-life batteries.

Do you have a powder-handling project?

I'm available to advise you and help determine the best solution.

Tarik, powder handling expert

UL Standards (Underwriters Laboratories)

UL standards are widely used in Canada to ensure battery safety. The main UL standards applicable include :

UL 1642

Safety of lithium-ion battery cells, including short-circuit, overcharge, excessive discharge and temperature tests.

UL 2054

Safety of battery packs for household and commercial appliances, including shock, vibration and life cycle tests.

UL 2271

Standard for batteries used in light electric vehicles, including rigorous testing to ensure safety in the event of thermal runaway, overcharging and excessive discharge.

UL 9540

Standard for energy storage systems, covering safety requirements for battery systems used in residential, commercial and industrial applications.

CSA (Canadian Standards Association) standards

CSA provides testing and certification services for batteries and energy storage systems. Key CSA standards include :

CSA C22.2 No. 107.1

Standard for energy storage systems, covering electrical safety requirements.

CSA C22.2 No. 60950-1

Standard for information technology equipment, including battery systems.

CSA C22.2 No. 0.17

Standard for rechargeable batteries used in portable appliances.

Regulations on battery transport: Transport of Dangerous Goods (TDG)

The transportation of batteries, particularly lithium and lead batteries, is subject to federal regulations on the transportation of dangerous goods (TDG). Requirements include:

Compliance with TDG Act requirements:

All battery shipments must comply with TDG Act requirements.

Certificate of Equivalency (CE):

As lead-acid batteries are non-compliant dangerous goods, all shipments must comply with a Certificate of Equivalency issued by Transport Canada.

TDG training:

Shippers, carriers and consignees must have valid TDG training and a TDG certificate.

Health and safety regulations

WHMIS (Workplace Hazardous Materials Information System)

The Workplace Hazardous Materials Information System (WHMIS) is essential for the management of hazardous substances in Canadian workplaces. Requirements include:

Labeling and Safety Data Sheets (SDS):

Batteries containing hazardous substances must be properly labeled and accompanied by SDSs.

Worker training:

Workers must be trained in the safe handling of batteries and the associated risks.

Canadian battery manufacturing standards cover a wide range of requirements to ensure product safety, worker protection and environmental sustainability. Provincial and federal regulations, UL and CSA standards, as well as transportation, health and safety requirements, all play a crucial role in structuring this industry. Compliance with these standards is essential to ensure the conformity, safety and performance of batteries manufactured in Canada.

In addition to these specific standards, the battery industry is also subject to general regulations on occupational health and safety, environmental protection and corporate social responsibility. Companies must comply with these standards and regulations to guarantee the quality and durability of their products, protect the health and safety of their employees and minimize their environmental impact.

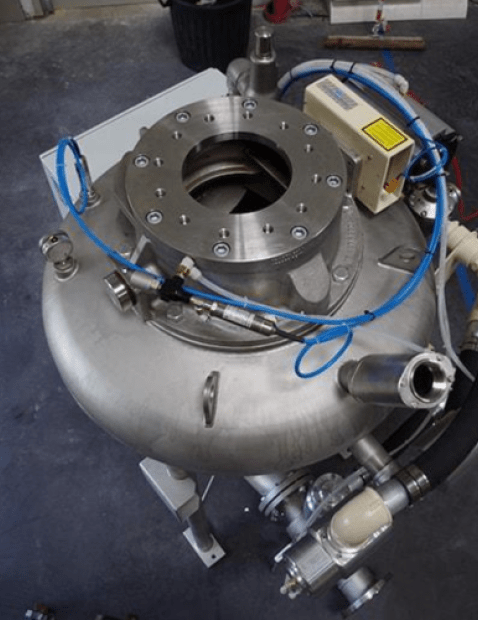

Case study: Discharging station of bulk bags of cadmium in very high containment