Dosing and weighing pyrotechnic powders: Key safety aspects for the defence industry

The use of pyrotechnic powders plays a central role in many strategic sectors, particularly in military establishments and the fireworks industry. Whether it is the processing of pyrotechnic products for the armed forces or the manufacture of fireworks for controlled use, mastering these highly reactive substances is a major challenge.

These powders, which are both powerful and unstable, require strict protocols from the moment they arrive at the factory until their final integration into weapon or signaling systems. The history of industrial incidents linked to the improper handling of these materials clearly illustrates the importance of rigorous management. In this context, specialized processing units must comply with specific standards to guarantee the reliability of products and the safety of operators.

In France, several reference sites ensure controlled production, in close connection with the requirements of military applications.

1. Why dosing and weighing pyrotechnic powders is critical ?

1.1 Importance of dosage accuracy

In the military field, the accuracy of the dosage of pyrotechnic powders is a determining factor in guaranteeing the performance of the products used in the field. Incorrect calculation of proportions can cause serious failures, even critical incidents. The history of pyrotechnics is full of examples illustrating the dangers of improper use of components.

A famous case dates back to the First World War: shells with the wrong dosage, containing an excess of ammonium perchlorate, caused premature detonations in the rear lines, resulting in losses for the French armies. More recently, failed tests on ballistic missiles have been attributed to an imbalance in the dosage of oxidizer and binder.

These errors illustrate how essential rigor in technical dosing areas is. Every gram counts. In a factory producing fireworks for military use, the slightest variation compromises the chemical stability and reduces the operational efficiency of the equipment deployed.

1.2 Homogeneity of mixtures and operational challenges

The homogeneity of pyrotechnic mixtures is just as crucial as their dosage. In technical manufacturing sites, components such as black powder, hexogen and potassium nitrate must be perfectly distributed to guarantee a uniform reaction. This is particularly true for fireworks embedded in missiles or fragmentation ammunition, where any variation leads to unpredictable behavior.

Take the example of a surface-to-surface missile: an inhomogeneous composition can slow down the propulsion phase, alter the trajectory or even cause a partial explosion in flight. In the context of the armed forces, these failures can have major operational consequences, ranging from mission failure to loss of life.

Establishments specializing in the production of pyrotechnic equipment in France attach the utmost importance to the uniformity of mixtures. Automated weighing systems and synchronized screw dispensers guarantee constant distribution, in accordance with mandatory technical standards. These processes make it possible to comply with standards while ensuring reliable and reproducible use of powders in critical situations.

1.3 Safety of specialized units and operators

The handling of pyrotechnic powders in a military context imposes strict safety rules, particularly in processing and dosing workshops. These substances are often sensitive to friction, heat or humidity. Their simple handling can become dangerous if the environment is not strictly controlled.

Incidents that have occurred in several European factories have shown that the accumulation of fine particles in the air can lead to dust explosions, even without direct contact with a flame. Hence the need for devices such as extractor hoods, earthing systems, or containment zones with an inert atmosphere. This equipment is now widely used in leading establishments to ensure a high level of safety.

The operators, trained in good practices, are also supervised by a rigorous technical management. Each station is designed to minimize the risks associated with the use of powders, while ensuring compliance with current standards. In France, several players such as Titanobel and Pyroalliance apply these strict protocols to guarantee the protection of people and infrastructure.

2. Suitable dosing and weighing technologies

2.1 Presentation of the main technologies

The dosing of energetic materials requires technologies that are robust, precise and adapted to the safety requirements of establishments working for the armed forces. The most commonly used systems are screw feeders, weight feeders and double weighing installations, specially designed to handle sensitive materials in high-risk environments.

Screw feeders are particularly suitable for poorly flowing powders such as black powder or certain perchlorate-based compounds. They allow for controlled use of the material, while limiting friction that can generate hot spots. This type of equipment is often installed in workshops with reactive compounds with a high level of containment.

Weight dosing, on the other hand, ensures dynamic and continuous weighing, guaranteeing extreme precision, even at very low rates. This system is preferred in military factories for complex load dosing operations, particularly in the manufacture of pyrotechnic products for missiles or signaling devices.

In all cases, these technologies are integrated into production lines that are completely secure and comply with the standards in force in leading establishments, particularly in France.

2.2 Process automation and control

In modern technical design lines, automation plays a key role in securing the weighing and dosing stages. It not only reduces manual use, a source of errors and risks, but also ensures the optimal use of pyrotechnic powders.

The automated systems are equipped with electrostatic charge sensors capable of detecting in real time any abnormal accumulation that could lead to accidental ignition. At the same time, temperature, humidity and pressure sensors monitor the environment to preserve the chemical stability of the mixtures. The integration of supervision software also enables the technical management to monitor each operation with precision.

Establishments such as Pyroalliance and PB Clermont have implemented these advanced monitoring systems to improve the reliability of their military fireworks processing flow. This approach promotes the repeatability of processes and considerably limits the risks associated with human or environmental variations.

Automation also guarantees complete traceability, which is essential in sensitive areas such as military pyrotechnics, where each batch must meet strict specifications.

2.3 Controlled environments and optimal conditions

In workshops that manufacture fireworks, the establishment of controlled environments is essential to ensure the safety of operators and the quality of finished products. Pyrotechnic clean rooms, for example, prevent any cross-contamination between different reactive substances.

Factories specializing in France, particularly in the military sector, use inert atmosphere chambers (nitrogen or CO₂) to stabilize sensitive powders such as RDX or HMX. These environments limit undesirable chemical reactions and guarantee consistent mixtures.

Containment tanks, extractor hoods and localized extraction systems help contain fine particles, thus reducing the risk of dust explosion. These facilities are now standard in all leading establishments working in the military and fireworks sector.

Have a project involving safe handling of pyrotechnic materials ?

I am here to support your development with expertise and tailored solutions.

Guillaume, expert in powder dosing and explosive material handling

3. Safety standards in military explosive production

3.1 International and national regulatory framework

The manufacture and use of active powder charges for military purposes are subject to strict regulations at national and international level. These standards aim to regulate the safety of technical facilities, operators and equipment, while guaranteeing product compatibility between the various partner armies.

Among the reference texts are NATO's STANAG agreements (Standardization Agreement), which harmonize the safety and performance requirements for military explosives. In the United States, the ITAR regulations (International Traffic in Arms Regulations) impose strict controls on the export of pyrotechnic technologies.

In Europe, the directive on explosive substances governs the handling, transport and storage of sensitive powders, as does ISO standard 14492, which defines the safety requirements applicable to explosive processing equipment.

French establishments, particularly those specializing in the production of powders and fireworks, are required to comply with all these frameworks in order to obtain the necessary authorizations. The management of each site plays a key role in the implementation and monitoring of these obligations.

3.2 Good practices and operational recommendations

Beyond official standards, good practices have become established in pyrotechnic manufacturing plants and operational sectors. These methods, based on feedback from the industry and the defense sector, help to reduce the risk of incidents when using powders.

The prevention of friction and impact is essential: equipment is coated with anti-spark materials, and the tools used are designed to prevent accidental initiation. The systematic grounding of all equipment eliminates electrostatic charges, which are responsible for many spontaneous ignitions.

In modern workshops, the movement of operators is controlled, and specific areas are assigned to the different stages of production. This rigorous organization makes it possible to maintain a high level of safety in all the establishments concerned.

3.3 Specific equipment to guarantee safety

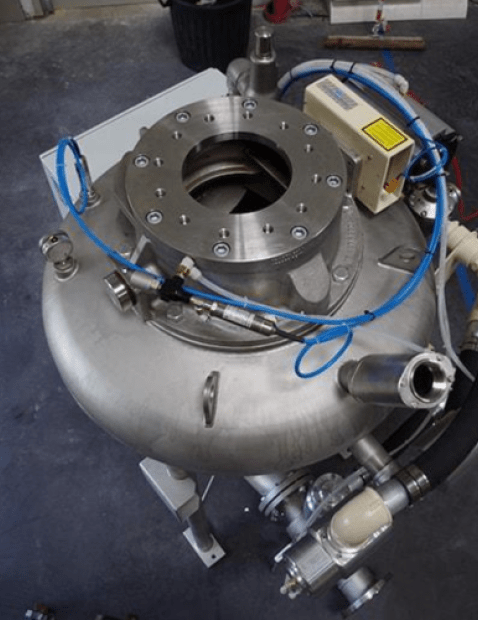

To ensure maximum safety when handling powders for technical explosives, several types of equipment have become essential in specialized factories. Dosing stations under an extractor hood, for example, considerably reduce the dispersion of particles in the air.

HEPA filters are used to capture high-risk microparticles, while the automation of production lines limits human intervention in critical areas. These facilities, integrated into workshops that comply with the requirements of defense customers, ensure a controlled environment that meets the strictest standards.

4. Our expertise

4.1 Brief presentation of the company

Palamatic Process is a French company specializing in the design of equipments for the handling, dosing and weighing of powders in sensitive environments. With a solid reputation in the pyrotechnics and military applications sectors, our company has been supporting manufacturers in search of efficient and secure solutions for more than 30 years.

4.2 Solutions offered by Palamatic

Our solutions are specifically developed to meet the requirements of the operational sectors of fireworks production and powders for military use. We offer weight dosing systems, containment stations, and integrated installations under controlled atmospheres. This equipment allows for controlled use of powders while guaranteeing operator safety and regulatory compliance.

Thanks to our expertise, several factories in France and abroad trust us to optimize their processes, from the receipt of raw materials to final packaging, in strict compliance with current standards.

Do you want to secure your pyrotechnic processes and increase the precision of your dosages ? Our technical teams are at your service to design customized solutions adapted to your specific use. Contact us today for personalized support and to increase the reliability of your installations.