Case studies - Energy

Palamatic Process has extensive experience with clients in various sectors of the energy industry. Fossil energies (gas, oil, coal), nuclear energies, as well as renewable energies, are sectors where the use of powders and bulk solids are present in a direct or indirect method.

Case studies with our customers

DeNox of a powership

Thermics Water and smoke Energy

Processed product: Solid Urea - AdBlue manufacturing by containerized process - Powerbarge / factory ship in New Caledonia.

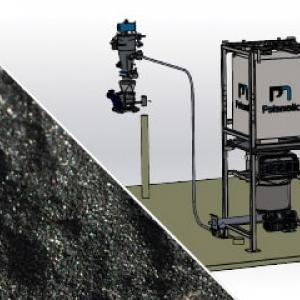

Pneumatic conveying and ashes storage

Water and smoke Energy

Processed materials: ashes - Incineration plant - Leading company in the supply of waste management and recovery solutions, expert in the whole waste cycle.

Rare earth recycling: optimised management with automated Big Bag emptying

Batteries and components Energy

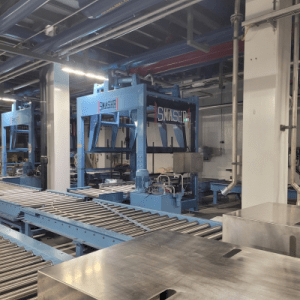

Automated production line: SmashR® Conv fragments the nickel blocks for smooth emptying

Batteries and components Energy

Automated bulk bag unloading and conveying system for lithium

Batteries and components Energy

Powders handled: Lithium carbonate (Li₂CO₃), iron oxide (Fe₃O₄), lithium Optimising automated bulk bag discharge for lithium powders

Optimization of Sensitive Powder Processing with a Custom Solution

Cement and plastering Pharmaceutical Nuclear Seeds industry Batteries and components Cosmetic and hygiene Paint and coating Thermics Veterinary Compound and plastic materials Defense Detergent and laundry powder Petrochemical Synthetic chemical Chemical Fine chemical Minerals and building Energy

Powders handled: lithium, NMC compounds (Nickel, Manganese, Cobalt), and anode/cathode materials (graphite, LiFePO4), which require secure handling due to their toxicity, hygroscopic nature, and...

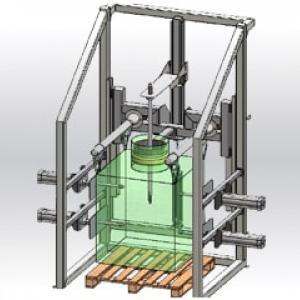

Automating big bag decompaction

Batteries and components Energy

Powders treated: hygroscopic powders such as metal sulphates Optimising the handling and unloading of big bags to improve safety and production

Complete line for breaking filter cake and bagging in big bags

Batteries and components Energy

Processed powders: nickel hydroxide, nickel sulphate and sodium hydroxide Recovery of nickel hydroxide cake for reconditioning in big bags

Complete automated lines for decompacting and emptying big bags

Batteries and components Energy

Processed powders: lithium, cadmium and oxides Decompaction and emptying of big bags for battery manufacture

Sack filling system for the manufacture of batteries

Batteries and components Energy

Treated powder: Lithium nickel manganese cobalt oxide - Turnkey solution for sieving, dosing and filling 22 kg bags of toxic powder. Improvement of ergonomics and operator safety.

Turnkey line for the manufacture of battery paste

Batteries and components Energy

Processed powders: zinc powder and additives. The aim is to improve the manual loading of the powders and to implement a complete automated system for accurate dosing of the ingredients into the...

Big bag emptying and dosing for the manufacture of copper collectors for electric batteries

Batteries and components Energy

Processed powders: carbon black, diatomaceous earth - The aim is to ensure perfect incorporation of these powders into the copper foil manufacturing process.

Automated deconditioning of big bags to increase nickel hydroxide production

Batteries and components Energy

Processed powder: nickel sulfate - Tailor-made solution to increase nickel hydroxide production in response to growing demand for electric vehicle batteries.

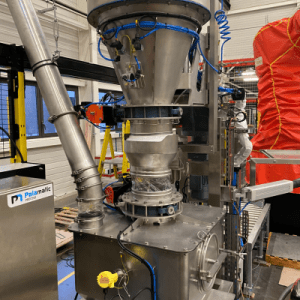

Disposal, dosing and pulping system

Batteries and components Energy

Treated powder: black mass - Black mass treatment process - Process to unload the black mass from big bags, precisely dose and repulp it with water, without clogging reactions or dust emissions from...

Automation of a big bag unloading system

Batteries and components Energy

Processed powder: Quartz - Quartz production process - A customized solution to automate the unloading of big bags for a world leader in the production of high-purity quartz.

Discharging station of big bags of cadmium in very high containment

Batteries and components Synthetic chemical Chemical Energy

Processed powder: cadmium oxide - Supply for battery manufacturing - The objective of this installation is to protect operators by avoiding the constraint of the working suit, which is very badly...

Handling big bags of toxic material for a battery manufacturer

Batteries and components Energy

Processed powder: lithium nickel potassium oxide - Unloading, filling of big bags and transfer of material - The objective of this installation is to protect the operators with equipment designed to...

Dosing and mixing line for military powders

Defense

Treated powders: ammonium perchlorate Safe preparation of pyrotechnic powders: automated dosing and mixing line

Aerospace: Automated emptying of ammonium perchlorate drums with DrumBot 300

Defense

Treated powders: ammonium perchlorate Secure automation of the emptying of drums of ammonium perchlorate in the aerospace industry with the DrumBot 300

Dosing of powder at the outlet of the dryer for packaging machine feed

Defense Energy

Cardboard box confined packaging station - Powder dosing line at dryer outlet for cardboard box packaging feed.

Unloading, conveying and dosing of toxic powder

Nuclear Energy

Processed product: Triuranium octoxide (U3O8) – Drum tipping station - The installation concerns the installation of a production system that empties, transfers and doses drums of a toxic product...

Preparation of electrolyte pool charges

Nuclear Energy

Processed powder: Potassium Bi-Fluoride - Drum and bag handling in the nuclear sector: 25kg kraft paper bags with an inner liner and 90kg drums with an inner liner.

Big bag discharging and pneumatic conveying

Thermics Energy

Processed powders: Cobalt Carbonate, Cobalt Hydroxide & Cobalt Oxalate - Tank feeding - The purpose of the installation is to feed a preparation tank with the product packaged in big bags.

Discharging of storage silos

Thermics Energy

Processed product: refiom, ashes - Loading of fly ash - Discharging of fly ash from storage silos for bulk truck loading.

Big bag filling in thermal power plant

Thermics Energy

Processed products: fly ashes and ash embers - Refiom processing line - Big bag filling in thermal power plant in a household waste incineration plant.

Mixing and feeding line for raw materials for cementing

Nuclear Energy

Processed powders: Cement + filler, lime and calcium nitrate - Cementation of nuclear waste - This process is intended for the cementation of fines and resins

- Bulk handling equipment is extensively used In the field of coal.

- In the port and oil fields, the dosing of additives is a frequent activity for Palamatic Process applications.

- Palamatic Process also has experience in the nuclear field. Our teams are specially trained to intervene on production sites (power plants) and also on reprocessing sites.

- Palamatic Process powder applications are also found in the manufacture of solar panels using silicon. Applications in the handling of machefer (solid residues of urban waste) have been handled by Palamatic Process in order to load big bags with the ashes for hazardous waste burial and long-term storage.