OEB containment equipment is specifically designed to meet the needs of the pharmaceutical, chemical, and food industries, ensuring the safe handling of powders and granules. By providing an effective barrier against occupational exposure (OEB 4 and OEB 5), these systems protect operators and maintain the quality of processed materials, including active pharmaceutical ingredients (API) and highly potent active pharmaceutical ingredients (HPAPI).

OEB (Occupational Exposure Band) containment equipment refers to industrial systems developed to limit exposure to active and hazardous substances. Designed in compliance with OEB classifications, these systems create secure working environments while adhering to strict environmental and health regulations.

Our systems are tailored to meet stringent safety standards while ensuring effective handling of hazardous substances.

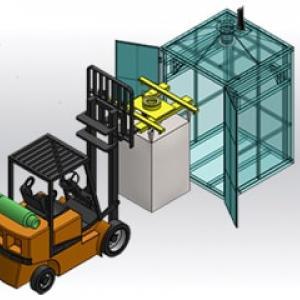

A secure transport solution designed to prevent particle dispersal.

Ideal for short- to medium-distance transport requirements.

To safeguard operators and prevent direct contact with hazardous or toxic particles, Collective Protective Equipment (CPE) is essential. These solutions include:

Installing CPE is critical to protecting operators by creating a barrier against direct exposure and maintaining the integrity of your production processes.

Palamatic Process's OEB-standard containment systems are specifically designed to handle a wide variety of powders, whether pharmaceutical, chemical, food-grade, or industrial. Commonly processed powders include:

Our equipment is equipped with Cleaning-in-Place (CIP) or Wash-in-Place (WIP) options, ensuring a reduction in cross-contamination risks and compliance with strict hygiene and traceability standards.

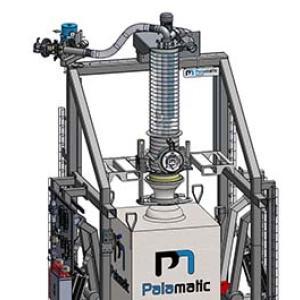

Palamatic Process offers modular and tailored equipment designed to seamlessly integrate into your production lines. An initial analysis ensures compatibility with mechanical configurations and process flows, while automation options optimise performance and safety.

This approach ensures optimum installation, complying with the requirements of standards OEB3 to OEB5, while limiting the risks of occupational exposure (OEL). The equipment can be coupled with automated systems, such as confined emptying stations, pneumatic transfer devices or dedusting solutions, to guarantee the safety of operators and the quality of the products handled.

Our expertise ensures a smooth and efficient transition, with comprehensive support from design through to integration and training of your teams. Our equipment is designed to improve your performance while complying with the strictest safety and industrial compliance standards.

Contact us for a customised containment solution. The Palamatic Process team is available to help you select the most suitable containment equipment for your emptying or transfer needs. Whether you require a hermetically sealed big bag emptying station or a dense phase pneumatic transfer system for sensitive powders, our experts are here to guide you every step of the way.