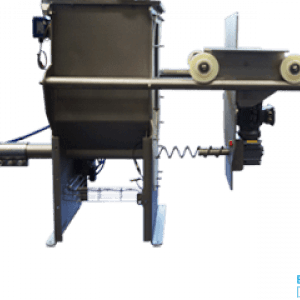

Screw feeder & vibrating feeder:

Palamatic Process has developed a wide range of dosing equipment.

Screw feeder - 4 models from D10 to D13

-

Dosage accuracy5

-

Hygiene4

Vibrating feeder

-

Dosage accuracy4

-

Hygiene5

Micro dosing spoon – SpoonMatic®

-

Dosage accuracy5

-

Efficiency5

-

Dosage capacity2

Vibrating hopper feeder – Precision microfeeder for powders and granules

-

Dosage accuracy5

The screw feeder is used to dose powders and bulk materials for all industrial sectors, in particular for the food, chemical, pharmaceutical and plastic sectors. The screw feeder allows a dosing without degradation of the bulk raw material while ensuring high precision.

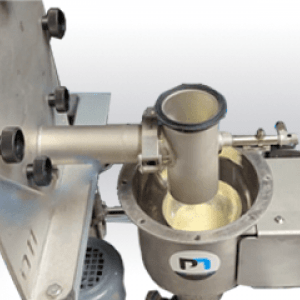

Palamatic Process also provides vibrating feeders. The vibrating feeder unit is used to dose fragile or delicate bulk materials. All parts in contact with the bulk material are made of stainless steel to avoid any degradation of the powder or bulk material.

The vibrating feeder extracts a more or less regular volume of bulk material from a hopper. The accuracy of the dosing units depends on the powder being processed.

You would like to set up a dosing system within your production line but are unsure about the most suitable solution? Discover our white paper on the subject: How to select your dosing system?