Case studies - Spices and flavors

Our strong knowledge of the world of the food industry offers you a guarantee of quality for the success of your production line and/or the integration of new equipment. Our offer includes, among many other systems, solutions for mixing, transferring, processing and packaging spices, herbs, spices, condiments and aromatic herbs.

The satisfaction of our customers depends on the management of all the stages of manufacturing your spice mixtures while respecting your ingredients.

Case studies with our customers

Pneumatic transfer line, mixing and packaging of food ingredients and flavourings at the outlet of the atomisation tower

Food and Animal Feed

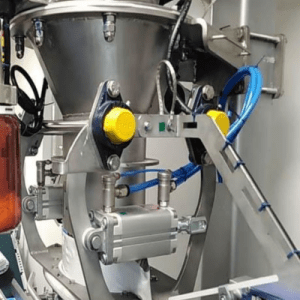

Integration of a D14 twin-screw dispenser on a PalSack packaging machine for spices

Food and Animal Feed

Automatic ingredient dosing and mixing line

Food and Animal Feed

Preparation station for additives, flavors and spices

Food and Animal Feed

Preparation station for premix ingredients

Food and Animal Feed

Mixing and packaging line in big bags and sacks

Food and Animal Feed

Mixing and packaging line

Food and Animal Feed

Bagging station for packing spice mixtures

Food and Animal Feed

Manufacture of fruit and vegetable powders for integration into ready meals and beverages recipes

Food and Animal Feed

Packaging of ingredients at the outlet of an atomization tower

Food and Animal Feed

Repacking of spices from storage containers

Food and Animal Feed

Spice packing with hygienic metering device

Food and Animal Feed

The industrial blending stage is usually a key stage in spice and flavour production plants. Read our article on the subject: Blending spices: What type of mixer should you use?