The mechanical transfer of solid materials requires reliable and efficient equipment to meet industrial demands. Palamatic Process provides you with customized solutions tailored to each type of production. Our bucket elevators, vibrating conveyors, and aeromechanical systems ensure precise, hygienic transport that complies with current standards, even in challenging environments such as ATEX zones. By choosing Palamatic Process, you benefit from comprehensive technical support and proven expertise.

Mechanical transfer is the ideal solution for industries handling bulk materials, whether powders, granules, or fragile products. This equipment ensures continuous and precise transport while meeting safety and hygiene standards.

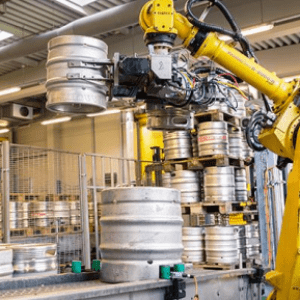

Bucket elevators provide vertical transport of solid materials, even in demanding environments. Their robust design, available in steel or stainless steel, ensures durability and safety.

Vibrating conveyors offer smooth and continuous transfer, ideal for fragile materials. These hygienic systems adapt perfectly to industrial needs, minimizing maintenance requirements.

Ideal for sensitive products, aeromechanical conveyors ensure homogeneous material transfer, even over long distances. Their self-cleaning system simplifies maintenance and extends service life.

Belt conveyors are designed to transport heavy or light loads over variable distances. Their modular design allows perfect adaptation to your industrial installations.

Vibrating troughs enable precise and hygienic transfer of granular or bulk materials. Their simplified design minimizes maintenance needs.

The maximum capacity of a bucket elevator depends on several factors, such as bucket design, belt or chain speed, and the type of material being transported. In standard configurations, bucket elevators can reach a capacity of 120 m³/h. However, this capacity can be adjusted to specific needs with customized dimensions and materials such as stainless steel for demanding environments.

The maintenance of a vibrating conveyor is designed to be simple and quick, thanks to optimized technical features. These systems generally include strategically placed inspection hatches for easy access to key areas for cleaning and inspection.

For demanding environments, additional options such as automatic cleaning systems can be integrated.

Aeromechanical conveyors are highly versatile and suitable for a wide variety of materials, thanks to their unique design combining flexibility and efficiency.

Whether for the food, chemical, or manufacturing industries, aeromechanical conveyors are designed to handle materials in specific conditions, such as ATEX zones or high-hygiene environments. Their versatility makes them an ideal solution for demanding processes.

Contact us for a mechanical transfer solution tailored to your needs. Palamatic Process teams are available to help you select the ideal equipment, whether it's a robust belt conveyor for heavy loads or a vibrating conveyor for fragile materials. Our experts are here to support you and meet your specific requirements.