Case studies - Chemical

With our extensive knowledge of chemical industry processes, Palamatic Process can offer you quality assurance in your production line and/or integration of new equipment.

Fields of application: seeds and crop treatments, powder paints and coating, rubber, polymers and plastics, synthetic chemistry, detergent and laundry, petrochemistry, paper industry, etc.

Case studies with our customers

Optimization of Sensitive Powder Processing with a Custom Solution

Cement and plastering Pharmaceutical Nuclear Seeds industry Batteries and components Cosmetic and hygiene Paint and coating Thermics Veterinary Compound and plastic materials Defense Detergent and laundry powder Petrochemical Synthetic chemical Chemical Fine chemical Minerals and building Energy

Discharging station of big bags of cadmium in very high containment

Batteries and components Synthetic chemical Chemical Energy

Rubber parts production line

Rubber Chemical

Preparation process for the micro-ingredients

Rubber Chemical

Bag unloading station for reactor loading

Rubber Chemical

Process for feeding 2 lines of carbon black from flowbins

Rubber Chemical

Preparation and dosing workstation for metal powders

Rubber Chemical

Inerting skid at big bag filling station outlet

Seeds industry Chemical

Drum dumping and discharging in Atex zone

Synthetic chemical Chemical

Discharging of drained automative filters

Petrochemical Chemical

Big bags and sacks unpacking for reactor feed

Synthetic chemical Chemical

Big Bag Compactor for the Agro-Chemical Industry

Seeds industry Chemical

Double packaging big bags of Polyethylene Flakes

Petrochemical Chemical

Unloading drums of toxic powder

Paint and coating Chemical

Mobile big bag filling station for zirconium under dryer

Synthetic chemical Chemical

Unloading and conveying FIBCs of titanium dioxide for the ink and coatings industry

Paint and coating Chemical

Unloading and handling of graphite powder

Compound and plastic materials Chemical

Turnkey solution for big bag unloading and vacuum conveying of rheology additives for chemical manufacturing

Paint and coating Chemical

High-rate automatic big bag filling line for the export of natural soda ash

Detergent and laundry powder Chemical

Big bag unloading and mobile IBC docking for powder paint industry

Paint and coating Chemical

Packaging line for washing detergents and detergent products

Detergent and laundry powder Chemical

Big bag packing station

Synthetic chemical Chemical

Big bag filling under silo

Compound and plastic materials Chemical

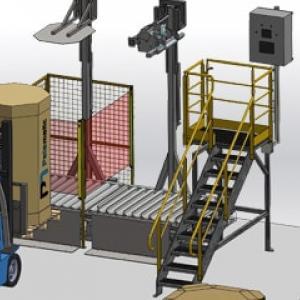

Drum and bin tipper for skip feeding

Petrochemical Chemical

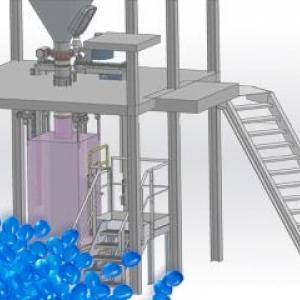

Container tipping of plastic granules

Compound and plastic materials Chemical

Discharge and pneumatic transfer of sodium nitrate

Synthetic chemical Chemical

Big bag discharge station

Paint and coating Chemical

Octabin Sealing System

Compound and plastic materials Chemical

Packaging of highly explosive powders in barrels

Synthetic chemical Chemical

Detergent powder milling

Detergent and laundry powder Chemical

Bulk solids supply to a manufacturing tank

Detergent and laundry powder Chemical

Unloading sacks for reactor feeding

Petrochemical Chemical

Pneumatic conveyor for mixer feeding

Paint and coating Chemical

Automatic loading of raw materials into reactors with integrated dosing

Synthetic chemical Chemical

Screening and packing skid for chromium powder

Synthetic chemical Chemical

FlowMatic® 04 automatic big bag packaging line

Seeds industry Chemical

Emptying of polypropylene bags for truck filling

Petrochemical Chemical

Discharging station for big bags of acid

Synthetic chemical Chemical

Discharge of big bags for truck tank filling

Petrochemical Chemical

Bag dumping for loading dough machines before coating

Compound and plastic materials Chemical

Atex 20 Loading of resins and polymers in chemical reactors under pressure

Paint and coating Synthetic chemical Chemical

Automatic bag emptying for feeding extrusion line

Petrochemical Chemical

Skid for unloading of bags of additives

Petrochemical Chemical

Big bag filling with corn seeds

Seeds industry Chemical

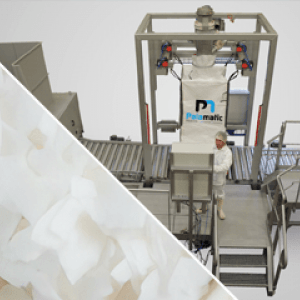

Automatic packaging line for big bags FlowMatic® 04: metering - conditioning - conveying

Seeds industry Chemical

One handle big bag filling with fertilizer

Seeds industry Chemical

Loading a chemical reactor from bags and big bags in ATEX zone 01

Synthetic chemical Chemical

Raw material feed and lump breaking of resinous materials

Paint and coating Petrochemical Chemical

Loading of wagons with pulverulent

Petrochemical Chemical

Discharge of paint powder containers into big bag

Paint and coating Chemical

Process for tanning additives: Feeding a chemical dispersion process from sacks and flexible or rigid containers.

Paint and coating Chemical

Discharge of big bags of zinc raw materials into etching tanks

Paint and coating Chemical

Discharge of big bags of bleaching agents for tank feeding

Detergent and laundry powder Chemical

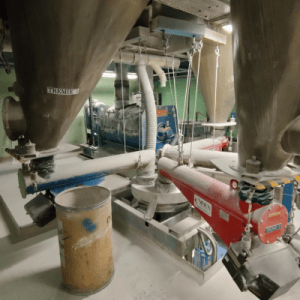

Laundry powder storage line

Detergent and laundry powder Chemical

Additives feeding for extrusion line

Compound and plastic materials Chemical

Raw material deconditioning unit, masterbatch mixture preparation and incorporation on extruder line

Compound and plastic materials Chemical

Discharging, conveying and dosing in a dough processing machine

Compound and plastic materials Chemical

Discharge and pneumatic conveying of fluorinated derivatives

Petrochemical Chemical

Discharging of big bags of activated carbon to a reactor in a contained way and under ATEX 22 atmosphere

Synthetic chemical Chemical

Discharge of bags for feeding a mixing tank

Cosmetic and hygiene Paint and coating Fine chemical

Automatic big bag unloading system for PET flakes and pellets

Compound and plastic materials Insect breeding

Our team of experts can supply processes for more difficult to handle chemical bulk materials with strict safety rules. By gathering the necessary data on your production process, we make sure that all regulation requirements and risks are taken into consideration for the final design, including: accidents, environmental pollution, chemical burns, poison, fire and explosion hazards.

Our offer includes:

- Compliance with ATEX and Class/Div standards

- Sanitary design with CIP "Clean In Place"

- Compliance with the rules of cross-contamination

- Containment of toxic substances

- Dosage of raw materials

- Dedicated production lines

- Respect for the integrity of bulk materials (product degradation, humidity, etc.)

- Material certificates and documentation requirements

- Automation for traceability of all your production batches

By working closely with our customers, we can define and customize the technical solutions suited to your manufacturing specifications and safety constraints (ATEX, inerting, toxic).

The wide variety of powders and bulk materials used in the chemical industry, depending on the nature of the product (solid, liquid, flammable, oxidizing, toxic, etc.), requires an expert level of knowledge for appropriate treatment and handling. Our team of engineers and technicians are trained in the integration of various equipment and process technologies.

Palamatic Process offers turnkey systems regarding the loading of raw materials for processes involved in the transformation of petroleum derivatives (plastics, synthetic fibers, etc.). Our equipment is used in different stages for processing of these raw materials including: storage to pneumatic conveying and from dosing to automation.

Examples of materials processed: clarcel, titanium dioxide, carbon black, antimony, epoxy-polyester, graphite, nylon, sodium oleate, resins, sulphur, silicone, thermo-plastic, varnish, zinc...

Our powder experts give you advice on handling chemical powders: things to know when storing chemicals, recommended equipment for handling toxic materials...