Bulk materials size reduction in industrial processes:

Palamatic Process provides machines for particle size reduction. The choice of system is made according to the material treated, the flow rate and the required granulometry.

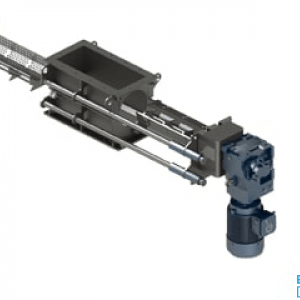

The industrial lump breaker crumbles the massed bulk materials and is particularly suitable for compact and cloddy materials.

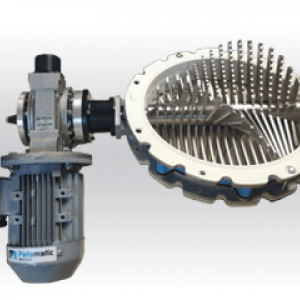

The industrial granulator ensures the deagglomeration of bulk materials. Granulation is possible thanks to the calibration trough.

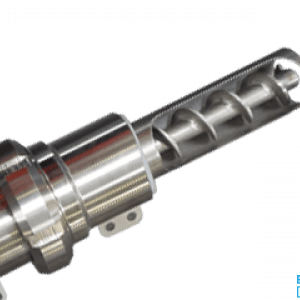

The industrial mill is designed for powder micronization and size reduction.

Vibratory screener - 3 models

-

Hygiene4

-

Rate5

-

Containment3

Centrifugal screener - 3 models

-

Rate5

-

Hygiene4

-

Ease of integration3

For 25 years Palamatic Process has been designing industrial grinding mills, lump breakers and granulators.

Palamatic Process grinding mills are developed to meet the needs of industries. We have the possibility to design your customized industrial shredder. Ideally used for powder micronization solutions, the industrial grinding mill is also available in ATEX version. Our powder experts will advise you on the choice of your mill: How to choose the right industrial mill?

In addition, Palamatic Process proposes 3 standard industrial lump breakers. We can also offer you a customized lump breaker according to your implementation and process constraints. The Palamatic Process lump breaker is ideal for crushing raw materials with a tendency to form agglomerates. Through a rotation of the knives on the industrial lump breaker, the clods are crumbled. Discover the 3 reasons to use an industrial lump breaker in your process.

Palamatic Process granulators are used to remove masses and effectively deagglomerate powder piles. The handling of powders is then easier, which makes it possible to obtain a better mixing of the product.