Breaking up products stored in big bags before the emptying phase

The SmashR® big bag crusher breaks up the lumps of products stored in big bags. With its two articulated hydraulic clamps and its ability to adjust the height of the big bag, the SmashR® big bag crusher ensures that product clumps are crushed without causing damage to the big bag material. This big bag crusher is available in 5 configurations to match all types of products and industries.

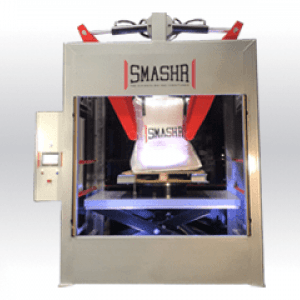

Big bag conditioner - SmashR® Enclosed

Models in the SmashR® range

The SmashR® Eco massaging cage is specially designed to break up big bags by breaking up product agglomerations.

Equipped with two articulated hydraulic gates and a height control system, it effectively crushes big bags without damaging them.

Suitable for a wide range of industries, this solution offers effective decompaction at lower cost.

The SmashR® is a versatile solution for crumbling products contained in big bags, facilitating emptying by breaking up product blocks.

Equipped with hydraulic cylinders, it enables big bags to be processed without damaging them. Adapted to all types of powders and industries, the SmashR® guarantees the fluidity of products stored in big bags.

Designed for big bags containing fine or hazardous powders, the SmashR® Enclosed massaging cage ensures dust-free, totally sealed operation.

The hydraulic equipment and rotating lift table are integrated into this confinement, with a dust extraction system. This solution facilitates big bag emptying while ensuring operator safety, and is particularly well suited to the chemical sector.

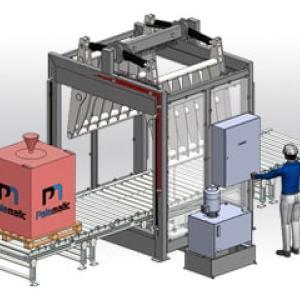

The SmashR® Conv big bag emptying station enables operators to independently decompact powders stored in big bags.

In its automatic version, it manages the massage cycles, their duration and the evacuation of the crumbled big bag, thus eliminating the need for repetitive interventions by the forklift operator. This solution optimizes production times and automates big bag crumbling.

The SmashR® Fly massage cage is a long-stroke version designed for large big bags. It breaks up powder agglomerations over the entire height of the big bag, up to 2.20 m. This version ensures efficient trimming of large volumes.