Weight batching systems for the handling of your bulk materials:

In order to meet the requirements of the industries, Palamatic Process has developed bulk dosing solutions. Our dosing equipment for bulk materials ensures a controlled supply of your process.

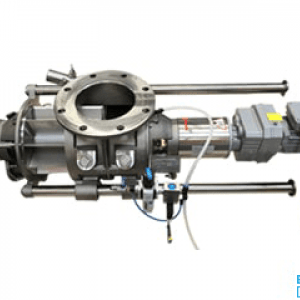

We design a wide range of rotary airlock valves: drop-through rotary airlock valves or blow-through rotary airlock valves, for pellets, chips or flakes and dust control rotary airlock valves.

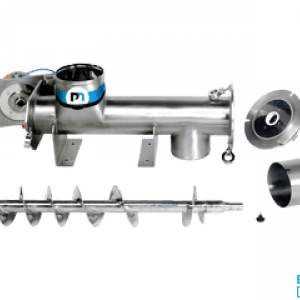

Our screw feeders allow volumetric or weight dosing. Our range covers throughputs from 1 to 10,000 l./h for handling powders and bulk materials.

Our complete range of industrial valves allows you to adjust the dosage and the volume of fluids. Our valves guarantee you many solutions for separating powders and bulk materials.

Screw feeder - 4 models from D10 to D13

-

Dosage accuracy5

-

Hygiene4

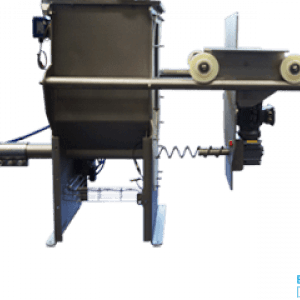

Vibrating feeder

-

Dosage accuracy4

-

Hygiene5

Dust control rotary airlock valve

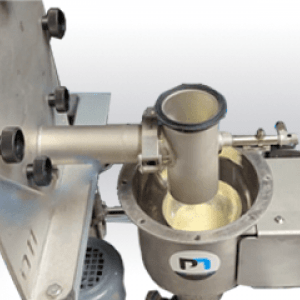

Micro dosing spoon – SpoonMatic®

-

Dosage accuracy5

-

Efficiency5

-

Dosage capacity2

Inflatek® valve - Inflatable seal

-

Containment5

Drop-through rotary airlock valve

Blow-through rotary airlock valve RVSC

Vibrating hopper feeder – Precision microfeeder for powders and granules

-

Dosage accuracy5

Rotary valve DN

-

Rate1

-

Dosage capacity5

Butterfly valve VPP

-

Rate4

-

Dosage capacity3

Contact us for expert powder advice for your project or consult our two dedicated white papers: How to select your dosing system? or How to select the right dosing equipment in 5 questions ?