Barrel filling, drum filler

For the filling of your bulk material in barrels (with bung holes), Palamatic Process provides you with the equipment of the PalDrum® range. We can provide you with customized equipment for powder and bulk product kegging operations.

Paldrum®01 drum filler - Screw feeder

-

Rate2

-

Automation1

-

Containment2

PalDrum®02 Barrel filler - Vibrating feeder

-

Rate4

-

Automation3

-

Containment3

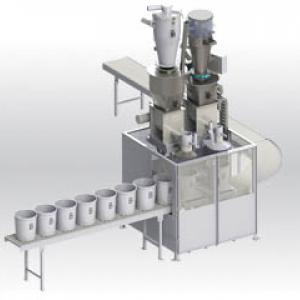

PalDrum®03 automatic barrel and bucket filling station - Twin-screw feeder

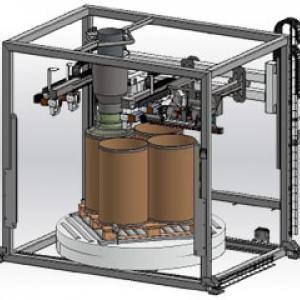

Paldrum®04 packaging for drums - Rotating pallet

-

Automation5

-

Rate5

-

Dosage accuracy4

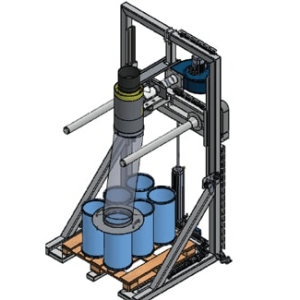

PalDrum®05 Drum and Big Bag filling station

-

Automation5

-

Overall dimensions4

-

Efficiency5

PalDrum®06 - Packaging for drums and big bags

-

Automation4

-

Ergonomics5

-

Containment4

Barrel manipulator - Drum handling

-

Ergonomics5

-

Ease of implementation4

Depending on the degree of hazardousness of the packed bulk material, our powder experts provide their expertise for the handling of explosive powders (ATEX).

In the same way, our range of machines meets your specific requirements for barrel filling. You can choose between semi-automatic and fully automatic filling systems.

Palamatic Process offers dust-tight barrel packing solutions for a healthy working atmosphere, free of dust particles. The barrel filling station performs a dosing by weighing and vibration to compact the bulk material. The packing is fully automatic using a roller conveyor system.

PalDrum® 01 barrel filling station: manual filling of barrel. This filling station ensures the packing of bulk bags and barrels.

PalDrum® 02 barrel filling station: semi-automatic filling of barrels.

This barrel conditioning station ensures automatic product dosing. Indeed, we install dosing equipment adapted to the processed bulk materials and the flow rates. The PalDrum® 02 barrel filling station is automatically positioned to ensure optimal containment.

PalDrum® 03 barrel filling station: automatic filling of barrels and buckets. The features integrated into this equipment are: containment during powder handling, dosing, commercial weighing, barrel conveying system.