IBC Container:

PEHD or PPH tanks - Liquid storage

-

Capacity3

IBC tumbler blender

-

Complexity of mixtures3

-

Rate2

-

Hygiene5

IBCFILL®01 IBC Container filling system

-

Containment5

-

Automation5

In addition to storage silos, Palamatic Process supplies a range of steel/stainless steel IBC containers and polyethylene containers. The stainless steel IBC container is suitable for storing powders with high hygienic constraints, which is particularly the case for food powders. This equipment is intended for handling bulk materials with a capacity that must be adapted to your needs.

This storage container is fitted with a butterfly valve that can be operated by a handle. The butterfly valve is located inside the container, which protects it from any damage that may be caused by the forks of the forklift truck.

All parts of our storage solutions are manufactured in our workshop. This guarantees the total quality of our equipment.

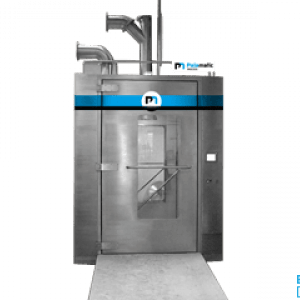

In order to maintain the hygiene of your process, we provide container washing stations. This washing station can be used to wash all types of containers.

In addition, in order to ensure complete containment during the conveying of your powders, we provide you with a flexible connector. The flexible sleeve is used to ensure total containment when conveying the material from the emptying station to the container. In order to handle your powders quickly, Palamatic Process designs, manufactures and installs pneumatic conveying systems that are based on transporting powder/bulk material from a sleeve filter inside pipes using air. The speed of the pneumatic conveying is adjustable.

This storage IBC container is available in ATEX version since potentially explosive atmospheres remain contained inside the pipes.

The Palamatic Process polyethylene container is ideal for the food and pharmaceutical industries. Our polyethylene storage solution offers total hygiene through deep cleaning.

In addition, in order to guarantee total hygiene on your production line, Palamatic Process can design a container filling system fitted with a magnetic detector before filling. This avoids incorporating any foreign bodies into the final product.

IBC container blending or IBC container tumbling is the most efficient method of blending bulk materials and powders during manufacturing processes. Tumble blending mix dense powders, fragile solids, raw ingredients and abrasive bulk materials. Tumble blenders are ideal when bulk materials mixes require gentle handling.