Description

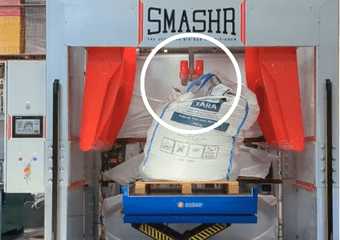

Big bag crusher - Preparation of the product before deconditioning

The SmashR® is a versatile solution for conditioning big bags, making them easier to empty by breaking up their mass. Equipped with hydraulic cylinders, it crushes big bags without damaging them. This solution can be adapted to all your powders, industries and applications. The SmashR® guarantees the fluidity of bulk materials stored in super sacks.

"Standard" operation cycle

- Operator loads big bag

- Operator starts massage cycle

- The clamps exert 4 upwards motion pressure on the big bag

- Table rotates 90°

- The clamps exert 4 upwards motion pressure on the big bag

- Table rotates 90°

- The cycle is complete and an information message indicates that the operator can retrieve the big bag.

- The number of presses and table turns is adjustable.

Duration of a "standard" cycle: 5 min.

Output: approx. 12 big bags/h

Force: > 15T / > 150 kN

Objectives: deagglomerate big bags

Equipment advantages

- Breaks up hardened blocks of powder, facilitating complete big bag emptying

- Clean process: powder is decompacted directly in the big bag

- Uses pivoting gates to reach the core of the product without damaging the big bag

- Adapts to big bag volumes and powder hardness

Media

View our equipment in videos

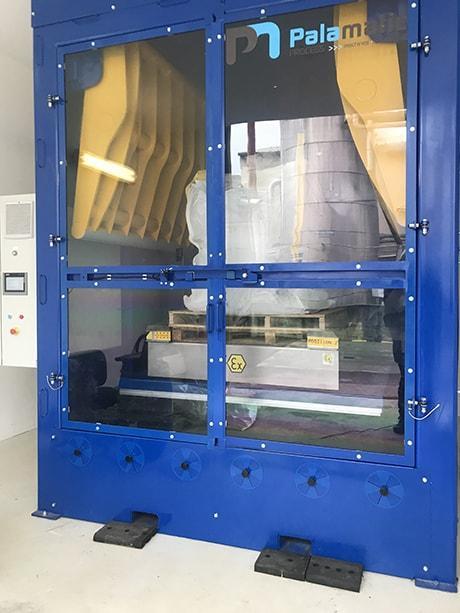

Big bag conditioner SmashR

Big bag decompactor for easy emptying of your product.

Control screen of big bag conditioner SmashR®

SmashR the ultimate big bag conditioner

View our equipment in photos

Big bag decompactor

The big bag decompactor or FIBC is the ideal solution for breaking up the mass of your products.

Easily unload big bags

SmashR® facilitates the flow of your product and allows for easy emptying of your FIBCs.

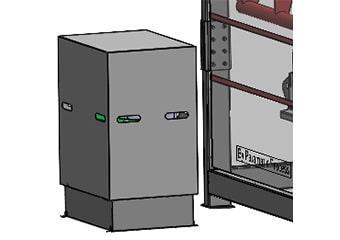

Remote control SmashR®

The SmashR® machine is controlled remotely via a dedicated PLC.

Decompacting the big bags

SmashR® the ultimate big bag conditioner decompacts your big bags throughout your production process thanks to its hydraulic massage system.

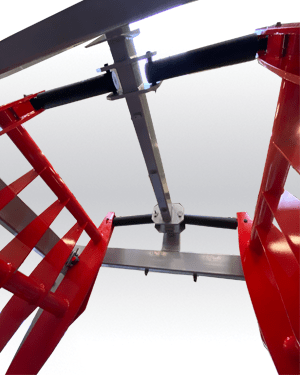

FIBC decompactor SmashR

Decompaction of FIBCs using the hydraulic cylinders of the SmashR massage cage.

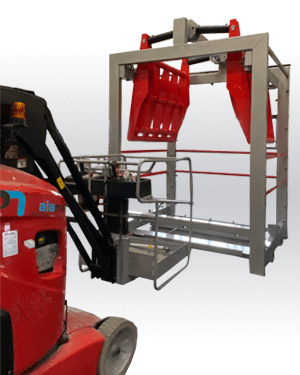

Big bag conditioner

The big bag conditioner optimises discharging for your production operators.

Big bag crusher

Crusher for big bags, the arms are operated by hydraulic cylinders.

Side puncher - Big bag unloader

The punching system is used to prepare the bulk bags before emptying.

Big bag conditioner

The crusher optimises discharging of your bulk products.

Big bag preparation

The punchers are operated by hydraulic cylinders.

Side puncher - Jumbo bag discharging

Prepare and break the blocks of bulk material before unpacking.

Touch-screen control panel

The operator selects the desired operating mode from several pre-set modes. Each mode is configurable.

Big bag conditioner

The massaging station comprises 2 pairs of hydraulic cylinders, enabling simultaneous massaging of 2 opposite sides of the big bag via the flaps.

Big bag unpacker

The massage station consists of 2 pairs of hydraulic cylinders, allowing simultaneous massage via the flaps on 2 opposite sides of the big bag.

Big bag crusher

The big bag is massaged by hydraulic pushers, which break up the mass of the big bag when it is "in block" to facilitate emptying.

Big bag massaging station

For product preparation prior to unpacking.

Features

Technical specification

| Rate |

12 big bags/hr |

|---|---|

| Force | > 15T / > 150 kN |

| External dimensions of the frame | 3,000 x 2,100 x 3,300 mm |

| Maximum lift table load | 1,500 kg |

| Carrier dimensions | 1,700 x 1,000 mm |

| Maximum big bag height* | 1,500 mm |

| Rise time | 25 seconds approx. |

| Descent time | 10 seconds approx. |

*If the height of the big bag is greater than 1,600mm, the SmashR® Fly is the appropriate model.

Standard" operating mode:

1. The operator inserts the big bag through the access door and places it on the turntable of the lift table.

2. The operator selects the desired operating mode from several pre-set modes. Each mode is configurable and takes into account :

- Big bag height

- Number of massage cycles

- the number of times the table is raised and lowered

- Number of rotations of the lift table plate

- Once the operating mode has been set, the operator launches the cycle from the control console.

3. The massage cycle starts.

4. An alert message informs the operator that the cycle is complete and that he can remove the big bag.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Raw materials deconditioning line

Processed powders: sugar and salt - Raw materials deconditioning line - The installation concerns a premix preparation line for the food industry.Food and Animal Feed

Production line for biomedical and nutraceutical products

Processed product: Sticky product - Production line in the parapharmaceutical and biomedical sector - Big bag unpacking unit for mixing final products.Fine chemical

Handling milk powder on production lines

Powder processed: milk powder Handling of milk powder on the production lineFood and Animal Feed

Handling of lithium, cadmium and oxide powders

Processed powders: lithium, cadmium and oxides Decompaction and emptying of big bags for battery manufactureEnergy