Description

Centrifugal screener - Controls and protects your production line

The centrifugal sifter allows the separation of foreign bodies from powders and granules. Waste is ejected towards the rejection output to guarantee high quality powders.

Centrifugal screener range

Manufactured from mild steel, stainless steel 304L and 316L

Throughput from 1 to 40 t/h.

3 models depending on the desired flow rate: RS200, RS300 or RS400

The Rotary centrifugal sifter ensures a clean product, without lumps, without debris, and protects your powder handling production line from mechanical damage. Therefore, it ensures a high-quality end product and is suitable for food, pharmaceutical, chemical and synthetic industries.

-

Rate5

-

Hygiene4

-

Ease of integration3

Equipment advantages

- Completely dust-proof

- Silent, no vibrations

- Mesh can be replaced in less than 2 minutes

- Easy to clean

- Double seal in engine shaft

- High throughput rate

Media

View our equipment in videos

Centrifugal screener

Bulk solids are metered into the cylindrical sifting chamber by means of a feed screw which discharges into a rotating helical paddle.

View our equipment in photos

Centrifugal sieve Palamatic Process

Centrifugal sieve protecting industrial production lines by eliminating foreign bodies.

Range of centrifugal sifter

Bulk material is metered into the cylindrical sifting chamber by means of a feed screw which discharges into a rotating helical paddle.

Centrifugal sieve food process

Quick and easy access to the inside of the centrifugal screen is crucial for maintenance teams.

Flour handling centrifugal sieve

Security sifting prior to packing process. The centrifugal sifter is fed thanks to an industrial storage container.

Centrifugal sieve opening for inspection

The inspection door is fitted with locks to make it easier to open the main body.

Centrifugal sieve on conveying line

The centrifugal screener feeds an industrial pin mill and is installed at the outlet of a bag dump station.

Industrial centrifugal sieve chemistry materials

The centrifugal sifter protects your production line from potential mechanical damages.

Industrial dextrose centrifugal sieve

The dextrose is carried into the screening grid via a screw feeder.

Centrifugal sieve food materials

The cylindrical mesh is implanted in the central hopper of the centrifugal sieve.

Centrifugal sieve

The centrifugal screener is provided with an inspection hatch that facilitates the change of meshes in two minutes and the complete washing of all smooth internal surfaces.

Housing with pulley under protective cover

The centrifugal sifter separates foreign bodies from powders, granules and bulk materials.

Centrifugal sieve Palamatic Process

The centrifugal screener is used for applications on production lines for the food, dairy and pharmaceutical industries.

Spices centrifugal sieve

Centrifugal sieve on a spice reconditioning line from storage containers.

Centrifugal sieve bulk materials handling

The purpose of the centrifugal sieve is to screen, sieve, deagglomerate bulk solids or perform solid separation.

Sugar sieving on confectionery processing line

Handling of ingredients present in the composition of confectionary products.

Overview of the sieve with grid

The centrifugal sieve controls and protects your production line.

Centrifugal sieve for food powder

The Palamatic Process centrifugal sieve offers the perfect solution for continuous screening of dry bulk materials: it breaks agglomerates during sieving.

Centrifugal sieve for milk powder

The removable cover at the end of the screener is used for quick cleaning or changing of the meshes.

Centrifugal sieve for iron hydroxyde

In the sieving chamber, rotating helical pallets continuously stir the bulk material.

Industrial centrifugal sifter

The centrifugal pressure forces the bulk materials through the mesh of the sieve.

Centrifugal sieve with screw conveyor

The blades of the sieve are never in contact with the mesh and are used to break up light agglomerates.

Centrifugal sieve

The bulk material to be screened arrives at the machine inlet either by gravity or by pneumatic conveying and passes through the cylindrical screening chamber with the use of a screw.

Oversize particules adjustment on industrial sieves

The waste is ejected to the reject outlet to guarantee high quality fines.

Centrifugal sieve Palamatic Process

Large particles and waste are discharged by the refusal at the outlet of the screener.

Centrifugal sieve for food industry

On gravity-fed vibrating screens, there is a large access hatch for internal inspection and cleaning.

Quick and easy disassembly of the centrifugal sifter

The centrifugal sieve carries out a particle size separation of the bulk material.

Centrifugal sieve Palamatic process

The choice of mesh types is defined according to the type of material handled: nylon, synthetic fabric, woven wire cloth...

Centrifugal sieve RS400

The centrifugal screener is used to sift, screen or deagglomerate bulk solids.

Centrifugal sifter below flexible fitting

The flexible fitting is used to ensure a tight process connection to the centrifugal sieve.

Centrifugal sieve RS400

The screen grid is available in different materials and sizes to suit the needs of each customer and bulk material specification.

Centrifugal sieve RS400

The Rotary centrifugal screen ensures a clean product, without clods, without foreign bodies and protects your production line from mechanical damage. It therefore guarantees a high quality final product.

Open centrifugal sieve RS400

On centrifugal screening machines with gravity feeding, there is a large access hatch for internal inspection and cleaning.

Centrifugal sieve RS400 Palamatic Process

The finishes and materials used ensure that the centrifugal screener is suitable for biochemical and pharmaceutical installations.

Centrifugal sifter on a food industry application

All our centrifugal sieves are available in standard, modified or specialized designs.

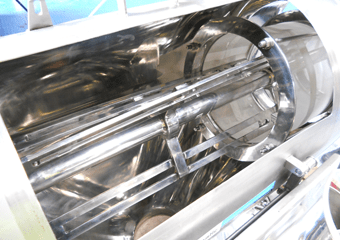

Internal view of the rotary sifter

The ROTARY centrifugal sieve protects your production line from mechanical damage.

Features

Technical specification

The bulk materials to be sifted is conveyed to the inside of the cylindrical sifter by the feeding screw.

The centrifugal force throws the product against the sieve.

The rotating paddles are not in contact with the mesh.

They force the product through the mesh, breaking lumps and agglomerates.

Waste is evacuated by a specific outlet. By the impact of powder, the sieve mesh starts vibrating to accelerate the screening and avoid the risk of clogging.

Dimensions

Sifter wall dimensions as per your requirements: from 50 µm to 5 mm.

| Model | Power | A | B | C | D | E | F | G | H | I | J | K | L | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RS 200 | 2,2 kW | 335 | 541 | 513 | 138 | 203 | 114 | 336 | 219 | 168 | 280 | 219 | 336 | 2,825 |

| RS 300 | 3.7 kW | 361 | 641 | 563 | 138 | 216 | 114 | 336 | 219 | 168 | 280 | 219 | 336 | 3,125 |

| RS 400 | 5,5 kW | 349 | 641 | 563 | 161 | 216 | 114 | 336 | 219 | 168 | 280 | 219 | 336 | 3,150 |

Les principaux avantages

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Spice production

Processed powder: paprika - Spice production - Industrial company specialized in the treatment of food additives. The purpose of the installation is to sieve the paprika powder for repacking into...Food and Animal Feed

Unloading big bags containing grains and cereals

Process products: wheat bran, wheat flour, disinsected wheat bran - Unloading big bags containing grains and cereals - This big bag emptying station aims to feed insects (larvae and adults) with dry...Food and Animal Feed