Description

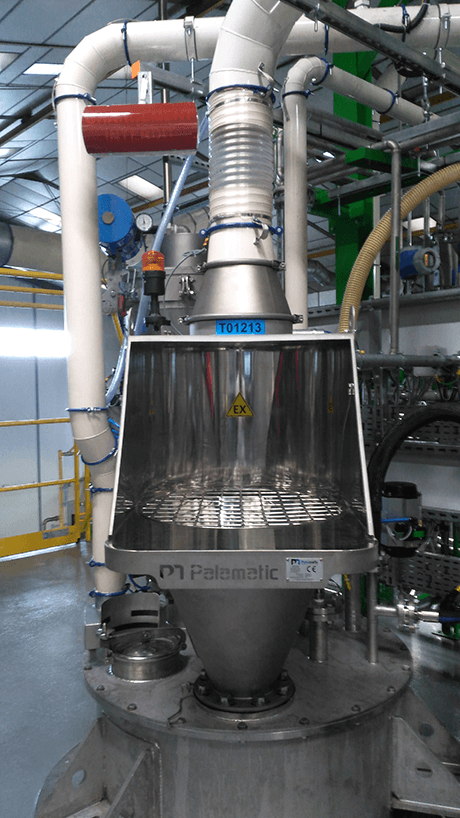

Hygienic manual bag dump

Hygiene and quality of production

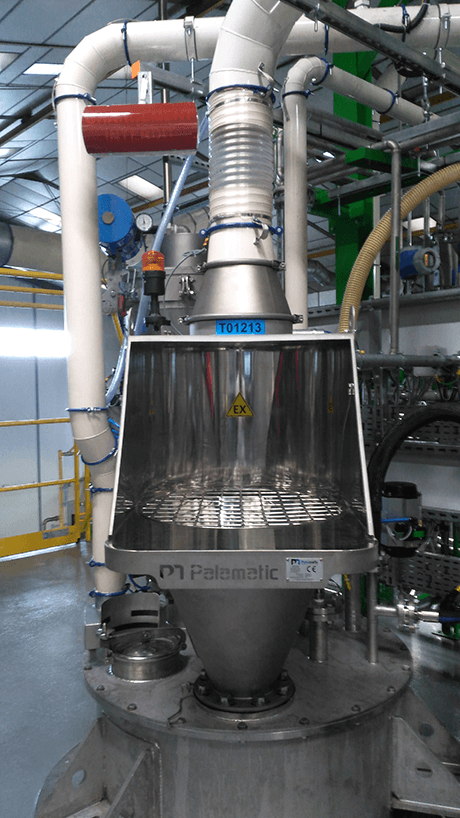

The Hygienic Sacktip® SH meets the hygiene and cleanliness needs of industries by ensuring increased protection against foreign bodies and a quality of your production.

Manual bag dump station integrated sieve range

Hygienic process solution with integrated sieve

The purpose of Palamatic Process' Sacktip® SH hygienic bag dump station is to protect your production against foreign bodies and thus guarantee its quality.

The custom-made and interchangeable integrated screen stops all the impurities contained in the bulk material of the bags. The vibrating motor improves the amplitude and intensity of the sieve. Its parameters are adjustable according to the flowability of the product and the mesh.

Operating procedure:

1. Open the door mounted on gas springs and place the bag on the removable table

2. Place the bag on the screen

3. Open the bag

4. Empty the bag

5. Activate the vibrating sieve to eliminate all foreign bodies contained in the bulk material

-

Rate2

-

Automation1

-

Hygiene5

Quick and easy cleaning

Equipment advantages

- Customized and interchangeable screen mesh

- Gas cylinder to optimize the ergonomics and to support the door

- Mirror polish finish

- Vibratory motor to improve the amplitude and intensity of the screen.

These settings are adjustable depending on the flowability of the materials and the mesh

Media

View our equipment in videos

Bag dump station with screener

View our equipment in photos

Gamme sacktip SH

Tamis intégré sur la vide sacs manuelle.

Manual sack discharging

Protection against foreign bodies.

Bag dump station

Gas cylinder to optimize the ergonomics and handling of the door.

Manual Bag dump station Palamatic Process

Manual bag dumping Palamatic Process:

- Protection of your processing production lines

- No foreign body

- Quality of your production

Sack dump station

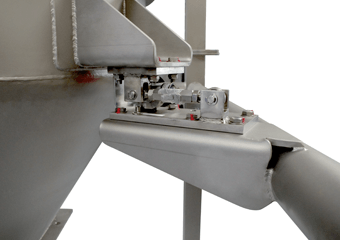

Custom-made and interchangeable sieve screen grid.

Bag tracking

For batch monitoring and process safety.

Customized bag emptying

Custom-made bag dump station with integrated bag compactor. The sack compactor reduces your waste and keeps your working environment clean.

Bag dump system

This bag dumping station integrates a complete liquid formulation line including:

- 3 big bag unloader stations for 7 types of bulk materials

- 3 reconditioning and unloading stations for industrial storage container

- 2 vacuumed pneumatic conveying lines feeding 2 reactors

Mirror polished bag dump station

This bag dump station integrates a complete liquid formulation line including:

- 3 big bag deconditioners for 7 types of raw materials.

- 3 stainless steel container reconditioning and dischargers.

- 2 vacuumed pneumatic conveying lines feeding 2 reactors.

Bag dump station with screener

Interchangeable mesh screen.

Feeding a big bag filling system with a bag dump

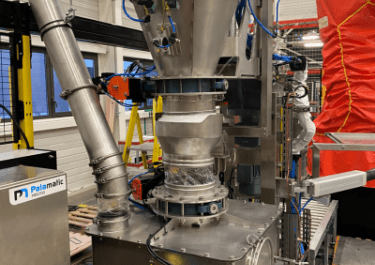

The Sacktip® SH model is a bag dump station with a vibrating screen integrated. During emptying, the bulk materials is transported directly to the FlowMatic® 02 big bag filling station using an easyclean conveying screw.

Packaging line

Integrated equipment :

Hygienic sack manual discharging - Sacktip® SH

Manual bag dump station integrated sieve

The screen grid is removable to facilitate the maintenance and cleaning of the bag dump station.

Manual sack discharging station integrated sieve

Easy handling, cleaning and changing of the screen grid in 2 minutes.

Bag dump station dust collection

Custom-made bag dump station for bulk materials discharging.

Manual bag dump station custom made

Ergonomically, the position of the bag laying tray promotes a low arm lift, thus minimizing tension in the elbow, shoulder and neck. The operator's working position is efficient and safe.

Manual sack discharging station integrated sieve

The Palamatic Process manual bag dump station is the ideal solution for extracting the contents of bags, of any type of bulk materials, containing raw ingredients or granular products, in a totally dust-free environment.

Features

Technical specification

| Flow rate | 2 to 6 sacks/min. |

|---|---|

| Access door | Painted steel, 304L stainless steel, 316L stainless steel, plexiglass, anti-static lexan, tempered laminated glass |

| Manufacturing materials | Painted steel, 316L stainless steel |

| Power | 0.5 kW |

| Mesh size | 500 µm to 5 mm |

- Sealing: EPDM, NBR, natural rubber, silicone

- Finishing touches: custom RAL, bead-blasting, electropolishing

Les principaux avantages

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Infant milk powder preparation

Product concerned: infant milk powder - Infant milk powder preparation - Industrial specialized in baby food production - The process consist of conditionning infant milk powder in diverse containing...Food and Animal Feed

Processing line for biscuit production factory

Processed powder: Crystal sugar - Line for biscuit factory - Food manufacturer that specializes in biscuits, chocolate and cocoa. The customer's process requirements involved the milling of granulated...Food and Animal Feed

Loading of kneaders

Processed powders: salt, flour, milk powder, sugar, ascorbic acid - Loading of kneaders - Worldwide company specialized in industrial bakery.Food and Animal Feed

Instant chocolate powder

Powder processed: chocolate powder - Instant chocolate powder - This company in the agri-food sector produces chocolates, sweets, condiments, seasonings, sugars...Food and Animal Feed

Mixing process for baby food

Processed powders: micronutrient powders - Mixing process for baby food - The customer is a Swedish manufacturer for an international distributor.Food and Animal Feed

Dosages of Dry Mix products

Processed powders: whey, sugar, flavorings - Dry products dosing for dry mixing - Preparation line for the manufacture of ice cream with unitary dosage of different ingredients according to the recipe...Food and Animal Feed

Safe preparation of pyrotechnic powders: automated dosing and mixing line

Treated powders: ammonium perchlorate Safe preparation of pyrotechnic powders: automated dosing and mixing lineDefense