Description

Sack manipulator - Vacuum tube lifter ensuring safety and productivity

Palamatic Process designed a vacuum tube lifter with sack lifter suction foot suitable for picking up loads up to 110 kg.

This sack lifting solution is suitable for industrial production lines involving raw ingredients and bulk materials.

Raw ingredients are often packaged in plastic and paper sacks and are delivered on pallets that have to be unloaded. Palamatic Process’s vacuum sack handler units perform this operation in a safe, efficient and cost effective manner.

This suction lifting system allows the operator to lift without effort sacks up to 110 kg. and increases his productivity and security.

Available in stainless steel, these bag handlers are ideal for the food and pharmaceutical industries.

Palamatic Process has the solution for all types of bags:

- Paper

- Plastic

- Hessian canvas (vacuum lifing head with spikes)

- Aluminium

-

Ergonomics5

-

Ease of implementation4

Equipment advantages

- Effortless lifting

- Increased performance and productivity

- Optimal working conditions

- Ergonomic post

- Increase in operator safety

- Increase in operator efficiency

- Low maintenance

Media

View our equipment in videos

Manipulateur de sacs

Manipulateur de sacs

Manipulateur de sacs Palamatic process

Effortless lifting & operator safety.

Vacuum tube lifter

Tube de levage par aspiration

For safe, effortless bag lifting.

View our equipment in photos

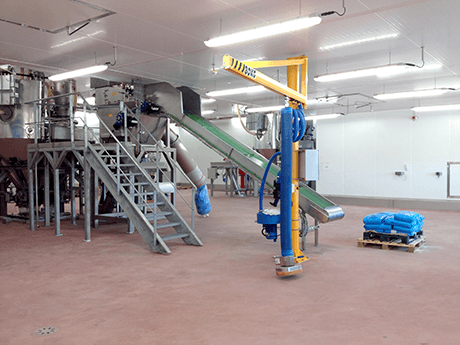

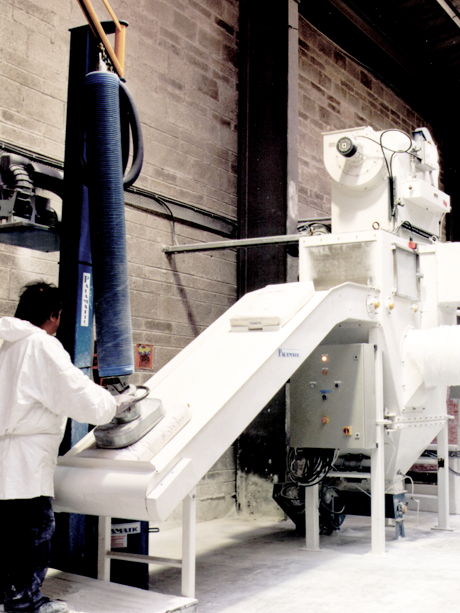

Sack manipulator

Bag handler for loading a Sacktip® manual discharging station.

Sack manipulator

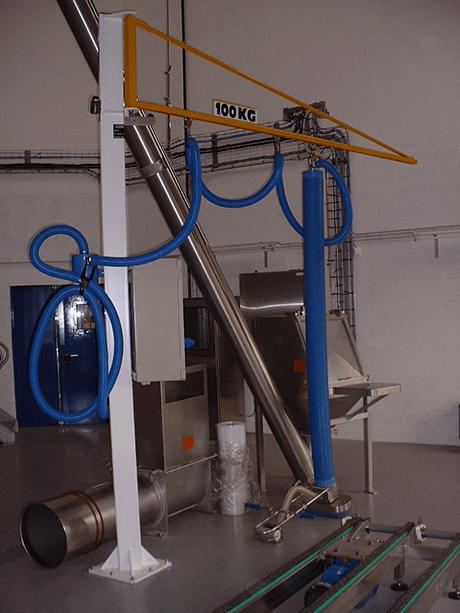

Lifting tube Ø 160 mm, stroke 1700 mm, free rotation 360°.

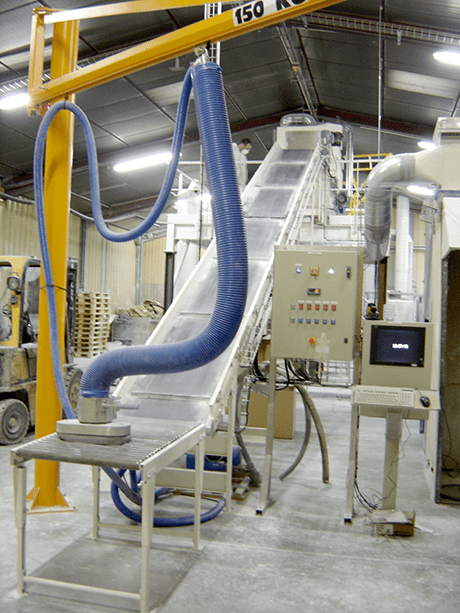

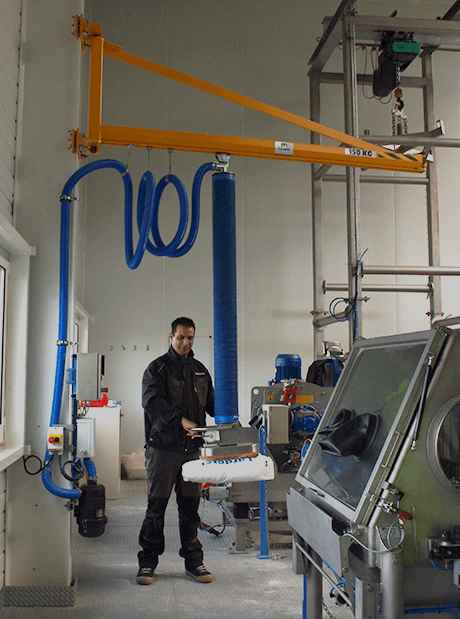

Vacuum bag lifter for unpacker infeed

The jibs are fitted with stops and carriages for attaching grippers and suction hose.

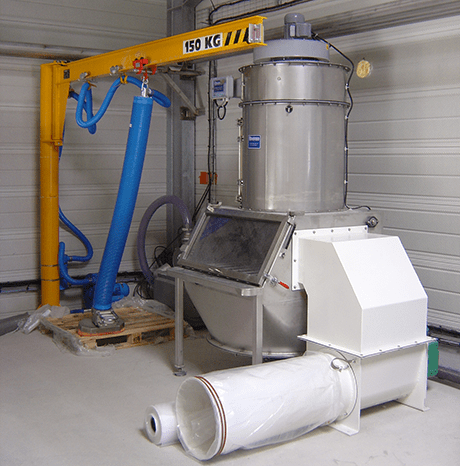

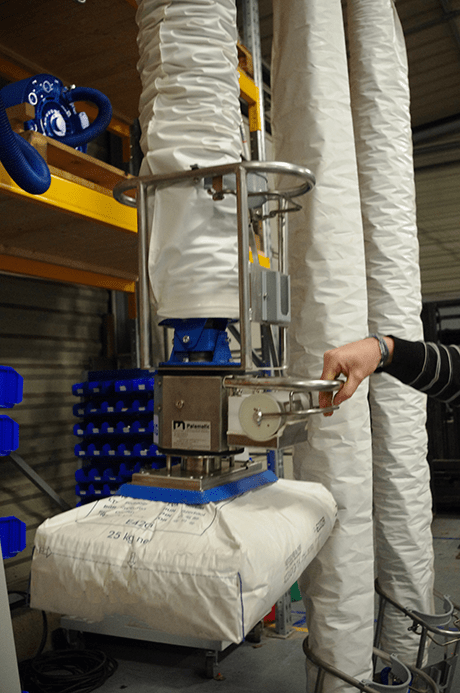

Industrial bag manipulator with gripping handle

A lower suction head equipped with a control handle featuring a barrel for self-stabilization of the load at any height, with no need for adjustment (patented system).

Bag manipulator for manual bag feeder

Sack manipulator

Système d'aide à la manutention pour un levage sans effort de tous types de sacs. Handling aid for effortless lifting of all types of bags.

Sack manipulator Palamatic Process

Sack handling system with extended handle.

Vacuum sack handler

Sack manipulator with grippers.

Vacuum tube lifter industrial production line

Sack manipulator for automatic opening and emptying of bags of plaster, cement and starch.

Automatic sack loading

Automatic Minislit® bag feeder via conveyor belt.

Sack loading by suction system

The sack manipulator enables effortless lifting of all types of bags to feed industrial manufacturing processes.

Feeding a conveyor belt on an automatic unpacker

Varislit® automatic sack unloader fed by a conveyor belt.

Manual sack loading

To reduce operator fatigue and bad posture, the Palamatic PL160 manipulator enables effortless handling (weightlessness) of 25 to 50 kg sacks to the Sacktip® emptying station.

Lifting sack depalletizing Palamatic Process

Handling aid for industrial process sacks.

Palamatic Process sack lifting and conveyor belt feeding

Sack handler on industrial production line.

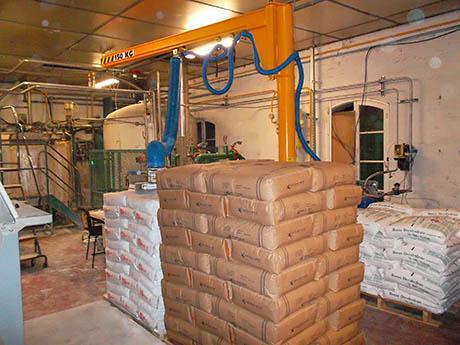

Vacuum sack lifter roller conveyor

The lifting tube is installed on an overhead crane to cover the entire area.

Industrial vacuum bag handling

The operator can effortlessly lift sacks of powders and bulk products.

Vacuum sack handling for automatic sack unloader feeder

The sack manipulator feeds automatic sack-opening machines on industrial production lines.

Sack lift for manual sack feeder

Lifting is effortless and increases bag loading speed.

Chemical sack handler

Emptying of nitrogen sacks for tank feeding in the manufacture of lye premixes.

Vacuum sack lifting system

Suction lifting tube to feed a confined sack hopper.

Sack handling aid for depalletizing

Lifting tube with suction pad gripper.

Palamatic Process ergonomic sack handle

The handle of the sack manipulator is raised to facilitate sack handling.

Suction lifting tube

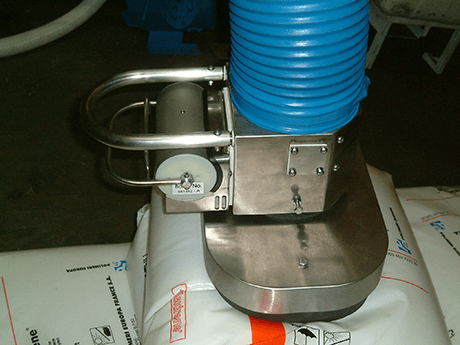

The suction pad with foam gasket makes it easy to handle the sacks without damaging them.

Gripper tube for paper sacks

The lifting tube of the sack manipulator is fitted with a protective cover.

Vacuum sack lifter handle for bag feeder

The suction pad adapts to the shape of the sacks for optimum support when handling them.

Burlap coffee sack handler coffee

The suction pad can be fitted with hooks for handling burlap sacks, for example.

Sack manipulator for automatic sack feeder

- Varislit® automatic sack emptier

- Sack handler

- Stainless steel container

Sack handler for depalletizing

Vacuum lifting tube for effortless sack handling.

Sack handler

The operator lifts the sack using the manipulator. The sack is then transferred to the emptying station. Finally, the powder is hygienically transferred to the industrial container.

Vacuum lifting to assist handling

Vacuum sack manipulator for loading a manual sack emptying station.

Suction lift head

Polyethylene bead sack manipulator for loading discharge hopper.

Sack manipulator for sack feeder

Once the sacks have been opened, the powder is mechanically transferred via a tubular conveying screw to a reactor.

Empty milk powder sack feeder

Sack handler on milk powder production line.

Suction cup manipulator

The operator feeds the Minislit® automatic sack discharging via a roller conveyor.

Minislit® automatic sack feeder

A roller conveyor allows the operator to place the sacks on the machine infeed.

Sack depalletizing

Feeding a Minislit® automatic sack unloader via a conveyor belt.

Indutrial sack handling aid

Handling aid for all types of sacks.

Features

Technical specification

Capacity: 10 to 80 kg/sack

Lifting range: 1,700 mm (2,400 mm possible)

Palamatic Process has the solution for all types of paper, plastic or jute sacks weighing up to 110 kg. The operator can maintain an output of 6 to 9 sacks per minute (depending on the surface to be covered).

These systems not only feed raw materials to all your process inputs, but also palletize your finished products.

A safety system is integrated into all systems, protecting the operator in the event of a power failure: the tube slowly relaxes, and the gripped load gently lands on the floor. There is no risk of the load falling (our systems are used for handling glass, car windscreens, TV sets, etc.).

All this with low maintenance for a highly efficient system.

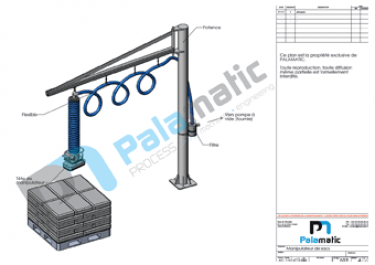

1. Jib crane on triangulated shaft, height under iron 3 m. to ensure a lifting stroke of 1700 mm.

2. Air inlet tube

3. Lifting tube rotates freely through 360°.

4. A lower suction lifting head equipped with a barrel-type control handle for self-stabilization of the load at any height, with no need for adjustment. Ergonomic handle design, approved without wrist strain

5. Wide suction cup for a better grip on the sack without deformation.

Not shown:

Direct-drive pump unit significantly reduces maintenance and noise (75 dB)

Air filter for handling dusty sacks

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Sugar dissolution for beverages

Processed powder: crystal sugar - Sugar dissolution for beverages - Company dedicated to the design of artisanal lemonade and artisanal syrup.Food and Animal Feed

Clean room for packing

Processed powder: milk powder - Clean room for packing - A leading dairy and manufacturer of high value-added milk powder for the leaders in the infant market.Food and Animal Feed

Manufacture of food flavours

Processed powder: maltodextrin with a bulk density of 500 kg/m³ - Manufacturing of food flavours - Company specialized in mushroom extraction - Maltodextrin is packed in 20 and 25 kg bags. The...Food and Animal Feed

Preparation of milky drink

Processed powders: milk powder and sugar - Preparation of milk drinks - Agribusiness group in the Island of Reunion, this company is a leader in most markets in which it operates: fresh dairy products...Food and Animal Feed

Ethanol production

Processed powders: fluorinated derivatives: ammonium bifluoride, sodium fluoride, potassium fluoride, magnesia - Ethanol production - This customer is a specialist in the processing of oilseeds for...Chemical

Plaster preparation

Processed powders: plaster, cement and starch - Plaster preparation - Leading company in the manufacture of plaster and plasterboards. The objective of this installation is to empty 25kg bags at high...Minerals and building

Tanning product

Processed powders: chemical additives - Tanning product - The great diversity of the products and their varied packaging meant that this plant had long been looking for a system that would reduce the...Chemical

Shampoo production

Processed powders: flake soda, lime powder, potash, magnesia - Shampoo production - This company in the cosmetics industry is involved in the implementation of industrial installations.Fine chemical

Compound line

Processed powder: polypropylene - Compound line - Installation of an automatic bag emptying system for polypropylene balls with a flow rate of 100 bags per hour.Chemical

Premix for coating

Processed powders: PVC powders - Premix for coating - This installation involves a manufacturer of coated fabric. Coating is a surface treatment that consists in applying a layer on a substrate (paper...Chemical

Bag and drum handling

Processed powder: Potassium Bi-Fluoride - Drum and bag handling in the nuclear sector: 25kg kraft paper bags with an inner liner and 90kg drums with an inner liner.Energy

Mixing and packing of spices

Processed powders: spice mixtures (curry...), tea and herbal tea blends, fine salt - Spice blending and bagging - Bagging station for packaging spice and powder blends in bags from 1 to 25kg.Food and Animal Feed

Manufacturing of engine additives

Treated powder: diatomaceous earth - Manufacture of engine additives - Safe incorporation of powders with nitrogen inerting sluice in a sensitive environment, ATEX gas zone, zero retention.Chemical

Manufacturing line for petfood industry

Processed Powders: Soy Flour, Brewer Yeast, Corn Starch, Dried Whey... - Manufacturing line for petfood industry - Manufacturering of dry and liquid flavor enhancers for the pet food industryFood and Animal Feed

Processing of artificial sweeteners

Processed product: erythritol - Bag emptying and crushing line - Production line for sauces, soups, drinks.Food and Animal Feed

Turnkey solution for the screening, dosing and filling sacks with toxic materials

Treated powder: Lithium nickel manganese cobalt oxide - Turnkey solution for sieving, dosing and filling 22 kg bags of toxic powder. Improvement of ergonomics and operator safety.Energy

Ergonomically designed bag dump station for the safe and contained handling of bags of sugar

Processed powder: granulated sugar - Bag opener for dust containment and operator ergonomics.Food and Animal Feed