Description

Containment and cleanliness of the process

Industrial dust collectors are used for dust collection or vacuum applications for industrial production lines involving raw ingredients and bulk materials handling. The built-in industrial dust collector can be flanged directly to equipment.

The built-in industrial dust collector is modular and integrates maximum operating and maintenance safety.

The built-in dust collector is ideally suited for processing powders with high dust emission. It is generally implanted under silos (to prevent explosions due to dust concentration), reception hoppers of pneumatic conveying.

The operator then has a clean working environment protected from all risks of contamination. Our Palamatic Process equipment is manufactured according to the standards in force in 2006/42/CE.

-

Rate5

-

Efficiency5

-

Ease of integration5

Possible configurations

Vertical

Horizontal

Equipment advantages

- High efficiency filtration

- Available with or without fan

- Easy maintenance, convenient maintenance height

- Replacement of filter elements without tools

- Long service life

- Low maintenance costs

- Hygienic operation

- Working in complete safety

Media

View our equipment in photos

Dust collector on hopper

Installation of a dust collector on a storage hopper for discharging dusty bulk materials.

Dust-collection on sack dumping unit fed with a sack manipulator

Double station for emptying crystal sugar bags and feeding sugar melter.

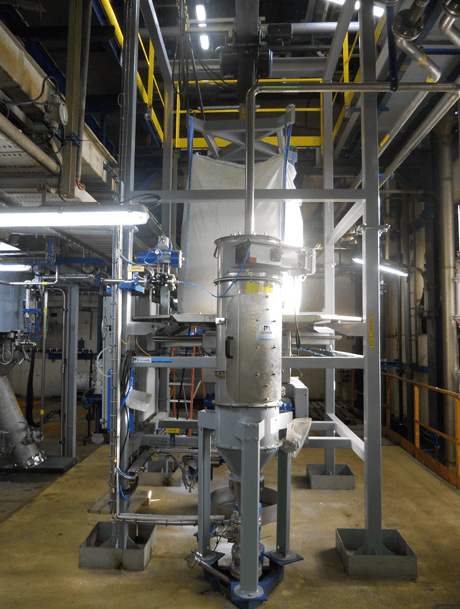

Built-in dust collection unit

Workshop for emptying bags for crusher feeding.

Dust collection on silo

Discharge, pneumatic conveying and dosing.

Dust collector bulk handling

Deconditioning of big bags of iron sulphates for silo repacking.

Industrial dust collection

Industrial dust collection consists in eliminating dust emissions by collecting them on the equipment.

Bulk materials handling dust collection

The dust collector keeps the working atmosphere clean for the operator's safety.

Built-in industrial collector on production line involving raw ingredients

Industrial air dust removal is carried out according to the principles of vacuum and filtration. This is used to control pollution and to have a clean working atmosphere.

Silo dust collection powder process

The silos are filled with cement for a building industry. The operator's environment is healthy thanks to the installation of a dust extraction system.

Bulk handling storage filtering

In the case of explosive dust, dust collection equipment meeting the ATEX directive will be provided.

Industrial filtration Palamatic Process

Palamatic Process designs and manufactures a wide range of filters, pumps and powder handling solutions for industry.

Bulk powder dust collection

Atex dust collector with vacuum and dust filtration (powders, raw ingredients and bulk products).

Manual bag dump station with dust collector

Industrial dust collection system for emptying titanium dioxide bags.

Dust filtering bulk handling equipment

Cartridge filter for powder coating.

Dust collector on bag dump station

Industrial dust collection on manual bag dump station fitted with a bag compactor.

Industrial dust filtration

The built-in dust collector is designed for the filtration and relative separation of medium, fine and impalpable dust.

Dust collector built in a big bag discharge station

Discharge and pneumatic conveying of feed additives to storage silos.

Food process dust filtration

Automatic big bag filling line for sugar packing.

Pneumatic vacuum transfer with detached filtration

The powder process is designed to load two melters from two big bag discharge stations.

Features

Technical specification

Filtering surface from 1 to 48 m²

Flow rate from 60 to 4,500 m³/h.

Industrial dust collectors have a stainless steel cylindrical body with flange connection that contains the filter ing elements. The automatic compressed air cleaning system is fully integrated in the upper module. The compact body is made of 304 stainless steel with integrated lower connection flange.

- High filtration efficiency thanks to wide range of B.I.A.-certified filter media

- Programmable electronic control panel installed including end-of-cycle cleaning system

- Filtering elements: circular sleeves, elliptical sleeves, cartridges, polypleat

- Reverse air jet cleaning system integrated inside access door for easy maintenance

- High cleaning efficiency due to solenoid valves incorporated in aluminium air tank

- "Full Immersion" solenoid valves incorporated in aluminium air tank

- Cover with safety device and key lock

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Sugar dissolution for beverages

Processed powder: crystal sugar - Sugar dissolution for beverages - Company dedicated to the design of artisanal lemonade and artisanal syrup.Food and Animal Feed

Wheat bran and lime premix line

Processed powders: wheat bran and lime with a bulk density of 0.4 to 1 kg/m³ - Wheat bran and lime premix line - Estonian engineering company specialized in the design of industrial operations for the...Food and Animal Feed

Animal feed

Processed powders: food additives - Animal feed - Specialist in additives for animal feed.Food and Animal Feed

Preparation of milky drink

Processed powders: milk powder and sugar - Preparation of milk drinks - Agribusiness group in the Island of Reunion, this company is a leader in most markets in which it operates: fresh dairy products...Food and Animal Feed

Icing sugar line

Processed powder: starch and granulated sugar - Icing sugar line - French sugar cooperative company - Supply and commissioning of a set of machines for the production of icing sugar and starch to feed...Food and Animal Feed

Ferric sulphates process

Powder processed: ferric sulphate - Ferric sulphate unit - This company in the construction industry offers different types of products such as cement, lime, binders....Minerals and building

Plaster preparation

Processed powders: plaster, cement and starch - Plaster preparation - Leading company in the manufacture of plaster and plasterboards. The objective of this installation is to empty 25kg bags at high...Minerals and building

Process of plasterboard production

Processed powder: plaster - Process of plasterboard production - French company producing and selling plaster, products derived from plaster and products based on expanded polystyrene.Minerals and building

Loading tank

Processed powder: very dusty and toxic bulk material - Loading tank - The objective of the installation is to contain the powder to avoid any dispersion during the different stages of conveying.Chemical

Blowing agent for PVC flooring

Powder processed: azobul - Blowing agent for PVC flooring - Continuous dosing supply of a PVC powder mixing reactor. The industrial metering system is fed by a vacuum pneumatic conveying system...Chemical

Product refining

Processed powders: ciclopirox, praziqantel - Product refining - French chemical group specialized in pharmaceutical fine chemistry, performance fine chemistry, advanced specialties - new technologies...Fine chemical

Sludge liming

Processed powder: Lime - Sludge liming - Manufacturer of dairy products - The project consists of adding lime at the outlet of the filter press for the treatment of water from the manufacturing...Water and smoke

Resin and gel coat manufacturing

Processed powders: maleic anhydride, Epo Kukdo - Resin and gel coat manufacturing - The customer is one of the world leaders in the production of structural resins for the building, automotive, water...Chemical

Truck loading with amino acids

Processed powder: amino acids - Truck loading with amino acids - This facility concerns a major player in the production and marketing of amino acids for animal feed.Food and Animal Feed

Sugar packing

Processed powder: white sugar - Sugar packing - The FlowMatic© 04 bulk bag filling station allows dust-tight packaging of all types of powders, limits dust emissions and automates the removal of the...Food and Animal Feed

Packing of white sugar and crystal sugar in big bag

Processed powders: white refined sugar, surfine caster sugar, crystal sugar - Packing in big bag of white sugar and crystal sugar - This big bag installation is designed to achieve a minimum flow rate...Food and Animal Feed

Disperser feeding

Processed bulk materials: pyrogenic silica, calcium carbonates, expanded graphite, aerosil, imersil - Disperser feeding - The facility consists of a bag dump station fitted with a dedusting device and...Chemical

Manufacturing of engine additives

Treated powder: diatomaceous earth - Manufacture of engine additives - Safe incorporation of powders with nitrogen inerting sluice in a sensitive environment, ATEX gas zone, zero retention.Chemical

Sugar grinding unit

Processed powders: icing sugar from white granulated sugar and starch - Sugar milling unit - The installation consists of feeding the mill with granulated sugar and then packaging the resulting icing...Food and Animal Feed

Filling of truck with cement

Processed product: cement - Filling of truck with cement - Two EasyFlow® EF100 big bag unloading stations for high-speed semi-automatic unpacking.Minerals and building

Déconditionnement et alimentation de cuves de préparation

Processed powders : Frying batter (flours, starches, spices, colourings...) - The installation concerns a pre-mixing line of ingredients for the food industry.Food and Animal Feed

Unloading and conveying of cement

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton big bags with pneumatic transfer of material to silo storageMinerals and building

Unloading and filling of manganese dioxide big bags

Processed powder: lithium nickel potassium oxide - Unloading, filling of big bags and transfer of material - The objective of this installation is to protect the operators with equipment designed to...Energy

Bucket filling line

Material: Graphite - Bucket filling line - Turnkey solution for big bag emptying, total containment and rapid filling of buckets with graphite powder.Chemical