Description

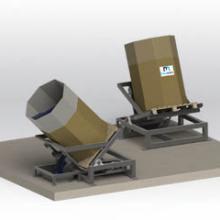

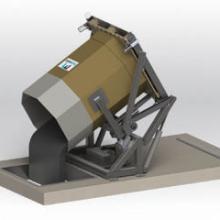

Octabin unloading - OctoFlow® 03 - Octabin turner for continuous high-flow use

This station allows you to temporarily transfer the contents of your octabins into a hopper. These wheeled hoppers can then be handled manually or via a forklift truck to be emptied at your various feeding points. Clamping systems for the hopper and pallet, octabin holding arms and a crown gearbox with high-strength bearing, allow safe turning.

In order to minimize the number of operator tasks, the vast majority of operations are automated on the Octabins 03 emptying station. This installation is intended for continuous use at high flow rate: it integrates the automatic decapping of octabins, their transfer, filling and weighing, closing and wrapping.

This line of conditioning aims at the continuous and high-speed conditioning of octabins (20 - 30 octabins/hour).

This equipment integrates the reversal of the octabin in the mobile base allowing a gravity discharge.

-

Rate3

-

Automation3

Media

View our equipment in photos

octabins

Octabins in industrial production lines involving raw ingredients and bulk materials handling.

Features

Technical specification

| Rate | 1.25 ton/octabin |

|---|---|

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power | 16.3kW |

| Compressed air consumption | 0.6 Nm³/h |

| Tilting angle | 180° |

| Finishing touches | RAL 9006, micro-blasted, electropolishing |

| Average power consumption | 4,1 kW |

| Operating pressure | 6 bars |

| Input 4 - 20 mA | 1 |

| TOR input | 13 |

| TOR output | 24 |

| Accuracy of the weighing chain | ± 500 grams |

| Dust removal rate | 300 m³/h. |

| Maximum size of octabins (Length x Width x Height) | 1,200 x 1,200 x 2,400 mm |

Operation procedure:

Step 1: Loading of the empty octabins with the forklift

Step 2: Automatic capping

Step 3: Transfer of the octabins

Step 4: Automatic filling

Step 5: Manual closing

Step 6: Automatic wrapping

Step 7: Extraction of the full octabins with the forklift