Processes powder: powdered sugar

Powdered sugar bagging

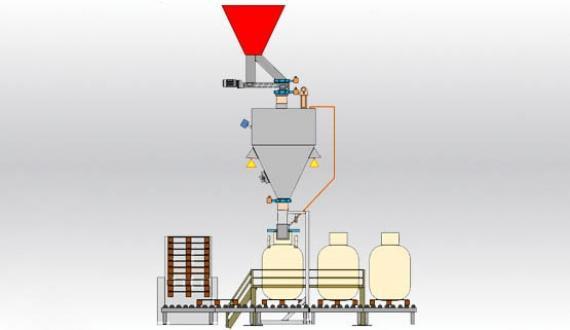

Our client is a company specializing in sugar manufacturing with a need to increase production capacity to meet the rising demand by global supply chains. Palamatic Process responded by integrating a FlowMatic® 06 bulk bag filling system.

Design requirements:

- Ergonomics: workstation adapted to the operator and designed to facilitate handling and promote efficiency

- Rate and precision: minimum of 40 bulk bags / hour with dosing precision provided by either a 4-20mA butterfly valve or an Archimedes screw feeder specially designed for this application

- Flexibility: The installation allows the packaging of many different raw materials (grain size and density) and is configurable with its acceptance module.

- Palletizing aid: automatic distribution of pallets by an unstacker that can contain up to 20 pallets simultaneously.

- Conveying and storage: a motorized roller conveying line allows the super sacks to be transported to a storage buffer / pick-up location via forklift

The proposed installation consists of a weighed buffer hopper with the same capacity as a bulk bag, which provides operation and production efficiency with the FlowMatic® 06 bulk bag filling station.

It is also equipped with a volumetric screw feeder, allowing precise control of the weight in the hopper.

This material dosing equipment is available in hygienic Easy Clean Design (ECD). Its dismantling and opening are simplified for cleaning operations by operators.

The FIBC filling station is equipped with automatic hooks, two of which move forward in order to optimize ergonomics.

A bulk bag or automated welding station is also available to seal the spout and minimize operator / powder contact.

The entire installation is controlled by a PalTouch® Technology touch screen interface. The PLC and its tactile interface offer the operator simple and flexible use of the machine while ensuring traceability (batch number, PO number, customer, packaged weight, date, time, bar code).