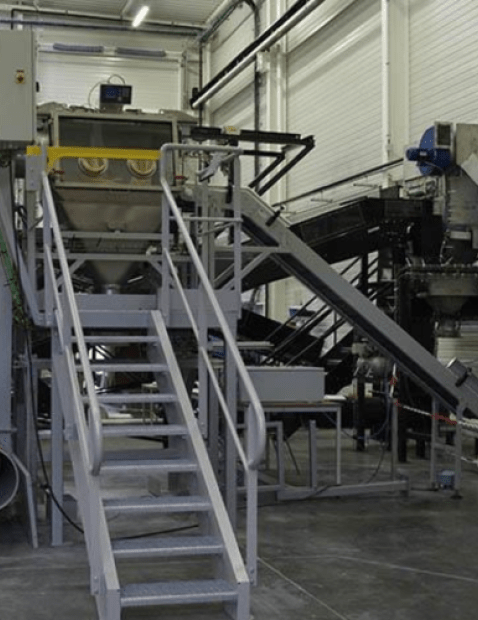

Incorporating ingredients into the manufacturing process lines requires the opening of 25kg bags of powder. In one day, production operators have to carry and open several tons of bags! To implement an efficient sack discharging stand, it must meet several criteria that we detail in this article.

1. The ergonomics of unpacking

Carrying the sacks is hard on the operators and can cause injury. Your unpacking stand should include a handling aid such as a bag manipulator. The sack manipulator will allow you to depalletise the ingredients on the different pallets positioned around the bag hopper.

The more pallets you have, the more relevant it is to install your bag handler on an overhead crane. Integrating your handling system on an overhead crane allows you to cover a large working area. This makes it easier for you to pick up your recipes.

2. Dust reduction

Opening bags is often characterised by the release of dust into the working atmosphere. Today, given the standards imposed, the installation of a dust collector on the bag emptying hopper is essential. Several alternatives exist to capture the dust emitted when the bags are opened.

You can, for example, opt for :

- A bag filter integrated directly on the bag emptying hopper

- A centralised filter with connection to the various bag emptying systems in the factory

- A suction arm at the bag loading points

- Containment by a glove box and SAS for introduction

- ...

Contact our design engineers to define the solution best suited to your needs and to address your ATEX issues if required.

Are you looking for a bag disposal system?

I am here to help you with your project.

Tarik, our bag discharger expert

3. Reduction of waste / empty bags

After discharging the sacks, it is important to dispose of the empty sacks in a clean manner, without dust generation and with limited waste volume.

To ensure a complete bag emptying system, Palamatic integrates empty bag compactors directly connected to the bag hoppers. These bag compactors allow the volume of bags to be reduced in a sealed manner. An Archimedean screw ensures the compaction of the empty bags in a plastic sheath. At the end of the bag opening campaign, the operator evacuates this sheath of empty bags into a waste bin. All these operations are carried out in a sealed manner, keeping your work area clean and safe for your operators.

Contact our project teams to design your entire bag opening station. Our showroom welcomes you to test manual bag pouring systems, automatic bag emptying systems and bag handling solutions.