Description

Anti-bridging device - Conical bottom for controlling the descent of powders and facilitating the flow of the product

The mechanical anti-bridging devices facilitate and regulate the downflow of powders under a storage silo or hopper.

The anti-bridging devices with conical bottom break up the clods and facilitate the flow of the material.

They are the solutions for the issues below:

Segregation Rat hole Bridging Retention

There are 2 principles of conical anti-bridging:

-

Efficiency5

-

Air consumption1

-

Noise level2

Rotating blades:

Conical screw:

Rotaring blades

Integral passage in the output flange

The anti-bridging devices with rotating blades with conical bottom are specially designed to be clamped on hoppers containing poor flowing powders.

The standard cone angle is 60°. It goes with two scraping rotating blades.

Its hollow shaft conception with offset geared motor provides full bore of the bulk material in the outlet flange.

This design makes possible the implementation of standard slide valve or butterfly valve for maintenance purposes.

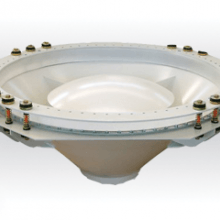

Conical screw

To boost the flow of powders and the feeding of the extraction screw

In order to carry out an extraction of moist and very clogging powders from a cylindrical and conical storage silo, Palamatic Process offers a mechanical fluidising system with conical screw.

The blade, positioned at the top of the blender ensures the breaking of the sloping and optimizes the useful volume of the hopper.

Also, the screw prevents the bulk material from caking and promotes their emptying.

The main advantage of this anti-bridging device is the implementation of the drive motor at the top of the hopper, which protects the central shaft passage from the powders.

The conception and the design of the screw are defined according to the handled bulk materials. The rotational speeds are slow and are less than 1 meter per second at the periphery.

This equipment is compatible with "Clean In Place" systems and ATEX certifications.

Equipment advantages

- Mechanical extraction without air or vibration

- Under silo mounting by simple flange

- Low power installed

- Tight and silent operation

- Quick installation

- Easy to assemble

- Dosing accuracy

Media

View our equipment in videos

Anti bridging device with conical bottom

View our equipment in photos

Anti-bridging device to help the flow of the materials

Conical anti-bridging device for discharging bulk materials and powders in industrial process lines.

Anti-bridging device with conical screw

Anti-bridging device to avoid bulk powder mass caking.

Conical screw

Conical screw in the anti-bridging device to facilitate the discharge of powders and the feeding of downstream process equipment.

Internal view of the mechanical anti-bridging device

Mechanical device to boost the flow of powders.

Flat mechanical anti-bridging device

Anti bridging device with flat bottom for controlling the discharging of powder into a storage hopper or silo.

Bin activator

The bin activator facilitates the extraction of bulk powders under industrial storage silos.

Electric vibrator

The electric vibrators are used to optimize the extraction of bulk materials and powders.

Pneumatic hammer

The pneumatic hammers are used in industrial production lines involving raw ingredients and bulk materials handling.

Fluidization plate

The fluidization plates are used to ease the homogeneous flow of powders and bulk materials.

Vibrofluidiseur

The vibrating bin aerators are used to facilitate the flow of powders and bulk materials.

Features

Technical specification

| Modèles | ØA | ØB | Puissance en kW* |

|---|---|---|---|

| DEVCY 200 | 200 | 600 | 2,2 |

| DEVCY 250 | 250 | 600 | 2,2 |

| DEVCY 300 | 300 | 800 | 3,3 |