Description

GENTLE Bulk BAG FILLING - Packaging of fragile products in bulk bags, crates or cartons

Objective: to package fragile, friable, brittle products in bulk bags.

Typical products packaged by the FlowMatic® 03 care bulk bag filling machine: cereals, dried fruits, cookies, vegetables, candies, chocolate balls, chewing gum, extruded products, pasta, puffed packaging materials, etc.

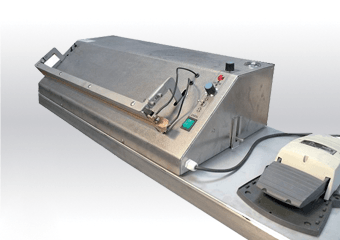

The design of the FlowMatic® 03 Care bulk bag packing station provides drop-off support to preserve the integrity of the product. The drop height of the products is reduced due to lifting the bottom of the bulk bag via the height transition features of the lower apron.

In addition to preserving fragile products, the structure of the FlowMatic® 03 Gentle bulk bag filling station is easily adjustable to fill bulk bags of different heights. The tension cylinder and the pre-forming fan provide optimal shape of the bulk bag to be filled.

The unique feature of this bulk bag filling machine is the ability to raise the bottom of the bulk bag. A second apron, equipped with a long stroke cylinder, allows the raising of the pallet on which the FIBC is placed. The bulk bag bottom transition technology is adapted according to your sector of activity: pneumatic cylinder, hydraulic cylinder or electric cylinder.

The apron of the bulk bag filling station is fitted with forks to allow the container to be held during lifting, as well as removal via forklift or pallet truck. This prevents fragile products falling from a significant height when packaging in bulk bags. This minimizes the risk of product breakage during the loading phases.

Discover our DryBulk-Mix® process line for mixing and packaging dry and fragile ingredients in bulk bags.

-

Fragile material5

-

Automation3

-

Overall dimensions5

Operational modes

- Pack in bulk bag:

At the start of the cycle, the lower apron raises to the desired stroke length.

In order to minimize creating folds in the bulk bag material, the use of an inflation fan is recommended.

As the filling progresses, the height adjustment cylinder (which provides the progressive descent of the super sack) keeps the filling tube just above the pile of product. The height management of the apron is ensured by either level probes, load cells or microwave sensor, depending on the fragile products packaged. The technology used for this FIBC conditioner minimizes the drop height by creating an automatic and regulated levelling in the conditioned bulk bag.

At the end of the cycle, the apron returns to the lowest position for removing the pallet.

- Pack in cardboard:

At the start of the cycle, the lower apron rises to maximum stroke.

As the filling progresses, the cylinder is controlled for the progressive descent of the box so filling tube is always just above the pile of product.

The height management of the apron is provided by the level probe, load cells or microwave sensor depending on the fragile products packaged.

At the end of the cycle, the apron returns to the lowest position for removal of the pallet.

The bulk bag filling FlowMatic®03 Care station is provided with all necessary equipment to ensure an effective conditioning operation: inflatable seal for dust containment and adjustment to various bulk bag inlet sizes, for adjusting the deck height controlled via a pneumatic cylinder, pre-forming bulk bag fan, bulk bag weighing system, commercial weighing, etc.

The entire structure is adjustable and allows the filling of bulk bags of different heights. The double-cased filling head allows volume balancing and prevents any dust emission into the work place atmosphere. The tension cylinder and the fan give the super sack an optimal shape. The handling of the filled FIBC is safe and stable to prevent falling over.

The FlowMatic®03 Gentle filling station achieves filling rates ranging from 10 to 20 bulk bags per hour.

Equipment advantages

- Respect for the products

- "Support" of the products drop height to preserve their integrity

- Commercial dosing and weighing of your powders

- Fan and tension cylinder to ensure the forming of the bulk bag and the internal liner

- "U" forks to allow the bulk bag removal by its handles and without a pallet

Media

View our equipment in videos

Bulk bag filling unit - FlowMatic®03

Big bag filling system - Flowmatic 03

Containment, densification and gross weighing

The FlowMatic® 03 Care filling station can be adjusted to fill bulk bags of different heights. The tensioning cylinder, the fan and the vibrating table give the bulk bag an optimal shape. The vibrating table ensures the deaeration of low density products.

Bulk bag filling range

View our equipment in photos

Chocolate bead process

The FlowMatic 03® Care super sack filler ensures that fragile products are not damaged.

FlowMatic® 03 Care

The FlowMatic 03® Care station is used to fill bulk bags with fragile products.

Super sack loader

The bulk bag packaging station is fed with ingredients via a mechanical conveyor screw.

Mobile FIBC packing station

The FlowMatic® 03 Care bulk bag packaging station allows the packaging of fragile products in bulk bags or cartons.

Filling of bulk bags under conveying screw

The filling station is equipped with a commercial weighing system for dried fruit.

Ingredients packaging station

The FlowMatic® 03 Care is easily adjustable to fill bulk bags of different heights.

Features

Technical specification

| Rate | 10 to 20 bulk bags/h. |

|---|---|

| Capacity | 2 ton/bulk bag |

| Manufacturing materials | Mild steel, 304L stainless steel |

| Installed power | 3 kW |

| Compressed air consumption | 0.9 Nm³/h. |

| Dust removal rate | 300 m³/h. |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 0.2kW

Operating pressure: 6 bar

Digital input: 6

Digital output: 6

Accuracy of the weighing chain: ± 500 grams

Maximum size of bulk bags: 1,550 (l ) x 1,550 (L) x 2,400 (H) mm

U-shaped forks: allow the removal of the bulk bag by the handles (optional)

Equipment integrated into the FlowMatic® 03 Care model:

- The apron fitted with a long-stroke cylinder allows the pallet on which the box or bulk bag is placed to be raised so that the packaged products do not fall from a great height.

- Round hooking forks of the bulk bag: offers easier sliding of the bulk bag handles.

- U-shaped forks for attaching the bulk bag handles: allow the bulk bag to be evacuated directly through the handles using a forklift truck (no pallet is used).

- Support structure: the structure is manually adjustable in height to fit all types of bulk bags- Width adjustment: the spacing of the hooking forks is adjustable in width to optimize the filling operation but provides a greater stability of the flexible container on its pallet.

- Inflatable seal: the inflatable seal ensures a tight connection between the filling head and the bulk bag during the filling operation.

- Filling head: the filling head is designed in a double casing for volume balancing. The charged air is evacuated through the degassing line which can be connected to the dedusting network.

- Tension cylinder: the pneumatic cylinder is located on the deck of the suspension forks. It allows to bring the system for attaching the handles of the bulk bag to ergonomic height, to adjust to the different bulk bag heights and to give an optimal shape to the bulk bag thanks to the permanent tensioning during the whole conditioning phase. The super sack is perfectly filled without any risk of pocketing and can be handled safely, without any risk of it tipping over.

- Pre-inflation fan: implanted on the station, the fan ensures the shaping of the bulk bag equipped with an internal bag to facilitate its filling. A by-pass valve makes it possible to degas the fines that are captured by the double-cased tube during the conditioning phase.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Chocolate beads handling

Processed products: chocolate beads - Storage in big bag - This customer is a world-renowned manufacturer and produces very fragile chocolate beads that are intended for packing (B to C).Food and Animal Feed

Optimization of the processing of agglomerated dried fruit

Products processed: dried fruit and vegetables Disaggregation of a large volume of dried fruitFood and Animal Feed

Receive your quotation in 3 clicks!