Description

Flexible silo - For storing your powder and granular materials

Volume from 3 to 56m³, filtering fabric and anti-dust

Palamatic Process can offer customized and economic storage solutions with our flex silo range of qeuipment. The flexible silo uses a high strength, porous fabric that allows air to circulate and the product to "breathe". Easier to transport then rigid silos, these flex silos are an easy solution that can be manufactured to accommodate almost any dry material and production requirement. One good example is these units can be used for the curing of polystyrene beads. Couple this silo with our screw conveyors for transfer of the contents inside.

These units are perfect for indoor or weatherproofed areas requiring storage of plastic pellets, grains, tea leaves, fiberglass and most powder or granular bulk solids materials.

-

Containment1

-

Capacity3

Equipment advantages

- Economical

- Filtrating fabric

- Fast and easy assembly / disassembly

- Permeable fabric

- Anti-dust

- Fabric is reinforced for added strength

- Anti-static fabric (optional)

- Vibrating extractor under flexible storage silo

Media

View our equipment in photos

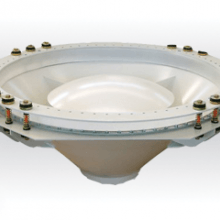

Flexible silo with bin activator

Optional bin activator to facilitate powder extraction.

Flexible silo for bulk materials handling

Simple and economical storage of your bulk materials.

Flexible storage silo

- Loading tube

- Safety valve

- Filtering cloth

Flexible storage silo sugar

The structure of the flexible silo is robust. The silo is provided with a galvanized steel frame.

Flexible storage silo

The flexible silo can be easily and quickly assembled and dismantled thanks to its compact design.

Flexible storage silo Palamatic Process

Economical solution with very low transport costs.

Flexible silo granules storage

The flexible silo fabric is porous and therefore very permeable to air to allow the product to ventilate.

Features

Technical specification

Characteristics of a standard flexible silo :

- Modular frame made of galvanized piping of suitable dimensions

- Silo body made of reinforced, permeable, dustproof fabric

- Top made of antistatic fabric suitable to filter the air when loading

- Loading opening made of fabric pipe diam. 100 mm

Dimensions :

Product range S : up to 12 tons :

|

Dim. |

A | mm. | 1,600 | 1,800 | 2,000 | 2,200 | 2,400 | 2,600 | 1,600 | 1,800 | 2,000 | 2,400 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dim. | B | mm. | 1,600 | 1,800 | 2,000 | 2,200 | 2,400 | 2,600 | 2,000 | 2,200 | 2,400 | 2,600 | ||||||||||

| Surface area. | C | m² | 2.56 | 3.24 | 4.00 | 4.84 | 5.76 | 6.76 | 3.20 | 3.96 | 4.80 | 5.72 | ||||||||||

| H.mm. | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | ||

| 1,800 | 3.1 | 1.8 | 3.74 | 2.2 | 4.4 | 2.6 | 5.1 | 3.0 | 5.6 | 3.3 | 6.2 | 3.7 | 3.5 | 2.1 | 4.2 | 2.5 | 4.7 | 2.8 | 5.3 | 3.2 | ||

| 2,000 | 3.5 | 2.1 | 4.3 | 2.6 | 5.1 | 3.1 | 6.0 | 3.6 | 6.7 | 4.0 | 7.5 | 4.5 | 4.1 | 2.4 | 4.9 | 2.9 | 5.6 | 3.3 | 6.4 | 3.8 | ||

| 2,200 | 4.0 | 2.4 | 4.9 | 2.9 | 5.9 | 3.5 | 6.9 | 4.1 | 7.8 | 4.6 | 8.8 | 5.2 | 4.7 | 2.8 | 5.6 | 3.4 | 6.5 | 3.9 | 7.4 | 4.4 | ||

| 2,400 | 4.5 | 2.7 | 5.5 | 3.3 | 6.6 | 4.0 | 7.8 | 4.7 | 8.9 | 5.3 | 10.0 | 6.0 | 5.3 | 3.2 | 6.4 | 3.8 | 7.4 | 4.4 | 8.5 | 5.1 | ||

| 2,600 | 4.9 | 2.9 | 6.1 | 3.6 | 7.4 | 4.4 | 8.7 | 5.2 | 9..9 | 5.9 | 11.3 | 6.8 | 5.9 | 3.5 | 7.1 | 4.3 | 8.3 | 5 | 9.6 | 5.7 | ||

| 2,800 | 5.4 | 3.2 | 6.7 | 4.0 | 8.1 | 4.9 | 9.6 | 5.7 | 11 | 6.6 | 12.6 | 7.5 | 6.5 | 3.9 | 7.9 | 4.7 | 9.2 | 5.5 | 10.7 | 6.4 | ||

| 3,000 | 5.9 | 3.5 | 7.3 | 4.4 | 8.9 | 5.3 | 10.5 | 6.3 | 12.1 | 7.2 | 13.2 | 7.9 | 7.1 | 4.2 | 8.6 | 5.1 | 10.1 | 6 | 11.7 | 7 | ||

| 3,200 | 6.3 | 3.8 | 7.9 | 4.7 | 9.6 | 5.7 | 11.4 | 6.8 | 12.7 | 7.6 | 14.5 | 8.7 | 7.7 | 4.6 | 9.3 | 5.6 | 11 | 6.6 | 12.8 | 7.7 | ||

| 3,400 | 6.8 | 4.1 | 8.5 | 5.1 | 10.3 | 6.4 | 12.3 | 7.4 | 13.7 | 8.2 | 15.8 | 9.5 | 8.2 | 4.9 | 10.1 | 6 | 11.9 | 7.1 | 13.4 | 8 | ||

| 3,600 | 7.3 | 4.4 | 9.1 | 5.4 | 11.1 | 6.6 | 13.2 | 7.9 | 14.8 | 8.9 | 17.1 | 10 | 8.8 | 5.3 | 10.8 | 6.5 | 12.8 | 7.7 | 14.4 | 8.6 | ||

| 3,800 | 7.7 | 4.6 | 9.7 | 5.8 | 11.8 | 7.1 | 13.7 | 8.2 | 15.9 | 9.5 | 18.4 | 11 | 9.4 | 5.6 | 11.5 | 6.9 | 13.2 | 7.9 | 15.5 | 9.3 | ||

| 4,000 | 8.2 | 4.9 | 10.3 | 6.2 | 12.6 | 7.5 | 14.6 | 8.7 | 17.0 | 10 | 19.6 | 12 | 10 | 6 | 12.3 | 7.3 | 14.1 | 8.5 | 16.6 | 10 | ||

Product range M : from 9 to 34 tons :

| Dim. | A | mm. | 2,600 | 2,800 | 3,000 | 3,200 | 3,400 | 3,600 | 2,600 | 2,800 | 3,000 | 3,400 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dim. | B | mm. | 2,600 | 2,800 | 3,000 | 3,200 | 3,400 | 3,600 | 3,000 | 3,000 | 3,400 | 3,600 | ||||||||||

| Surface area | C | m² | 6.76 | 7.84 | 9.00 | 10.24 | 11.56 | 12.96 | 7.80 | 8.96 | 10.20 | 11.52 | ||||||||||

| H.mm. | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | m³ | ton | ||

| 3,500 | 16 | 9 | 18 | 10 | 20 | 12 | 22 | 13 | 24 | 14 | 27 | 16 | 18 | 10 | 20 | 12 | 22 | 13 | 24 | 14 | ||

| 4,000 | 19 | 11 | 22 | 13 | 24 | 14 | 27 | 16 | 30 | 18 | 33 | 20 | 22 | 13 | 24 | 14 | 27 | 16 | 29 | 18 | ||

| 4,500 | 22 | 13 | 25 | 15 | 29 | 18 | 32 | 19 | 36 | 21 | 38 | 22 | 25 | 15 | 28 | 17 | 31 | 19 | 35 | 21 | ||

| 5,000 | 25 | 15 | 18 | 33 | 20 | 36 | 21 | 40 | 24 | 44 | 26 | 28 | 17 | 32 | 19 | 36 | 21 | 39 | 23 | |||

| 5,500 | 28 | 17 | 33 | 20 | 36 | 21 | 41 | 25 | 45 | 27 | 50 | 30 | 33 | 20 | 36 | 21 | 40 | 24 | 44 | 26 | ||

| 6,000 | 31 | 19 | 36 | 21 | 40 | 24 | 46 | 28 | 51 | 31 | 56 | 34 | 36 | 21 | 40 | 24 | 45 | 27 | 50 | 30 | ||

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

A compact, hygienic and mutlti-stream solution to safely feed process tanks

Processed powders: lactose, permeate, various milk powders Automating powder transfer and dosing in the dairy industryFood and Animal Feed