Description

Blow-through rotary airlock valve - Dosing of powder for feeding pneumatic conveying systems

15 models: flow rate from 5 to 38 liters/rev.

Cast iron, 304, 316L stainless construction

These rotary airlock valves, also known as blow through feeders, are designed for controlling the discharge rate of material from silos and hoppers by gravity or in pneumatic conveying (vacuum or pressure) lines.

Rotary airlock valves are designed for metering the feed of powdered or granular material in silos, hoppers, pneumatic conveying systems, bag filters and cyclones in powder handling processes.

Equipment advantages

- Compact, heavy duty construction

- ATEX, zone 22 version available

- Rotor surface treatment chrome-plating, nickel-plating, hardened blades

- Frame: cast iron or AISI 304/316 stainless steel

- Fixed speed of the rotor : 10, 20, 30 rev./min.

- Variable speed of the rotor : 4 - 22 rev./min.

- Frame surface treatment chrome-plating, nickel-plating, Teflon

- Motors: direct through a reducer, through a coaxial varidrive with chain transmission or no motor (bare shaft)

Media

View our equipment in photos

Volumetric screw feeder bulk materials handling

Adjustment of rotor blades according to the properties of each bulk material.

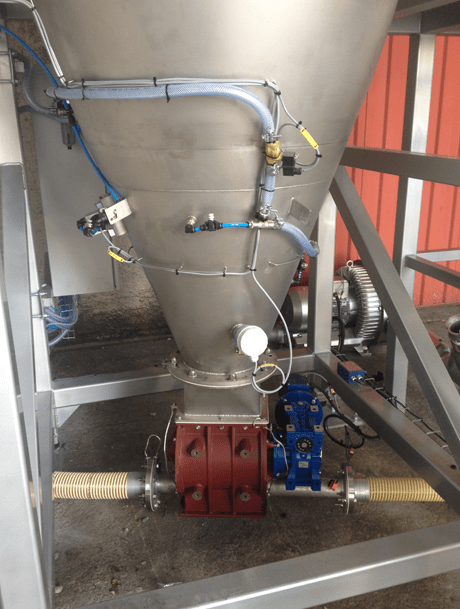

Blow trough rotary airlock valve under hopper

The rotary valves with lateral flow control provide powder dosing for feeding the pneumatic conveying system.

Blow trough rotary valve

Blow trough rotary valves are designed for cell extraction, gravity flow or pneumatic conveying applications.

Rotary airlock valve Palamatic Process

Palamatic Process rotary valves have been designed for use in the food and feed, chemical and pharmaceutical industries.

Rotary airlock valve

Body in cast iron or stainless steel AISI 304L/316L.

Rotary airlock valve salt

The blow through rotary valves are specially designed for pneumatic conveying applications. They can be mounted in line on the conveying pipe.

Rotary airlock valve Palamatic Process

The advantage of the rotary locks with lateral passage is that they can handle sticky powdery products.

Rotary airlock valve range

The passage of the conveying air through the airlock ensures that the rotor is cleaned by removing the adhered particles from the walls.

Sugar industry application

Production line for confectionery products.

Blow trough rotary airlock valve

Dense phase pneumatic conveying with integrated stainless steel hopper and dosing system.

Sugar dosing

Sugar metering for big bag packing.

Features

Technical specification

Two compartments are filled with product through the inlet at the top of the valve. After less than a half turn, the rotor discharges the product into the current generated by the velocity of air that passes through the lower part of the rotary airlock valve.

Inlet and outlet flanges are used to install the rotary valve to the pneumatic piping. The in-line connection of the rotary valve on the pneumatic piping provides the speed setting and feed rate of the bulk material to be processed. A degassing line may be connected to the valve body to balance the volumes and ensure optimal filling.

- Rotor: integral with rounded blades, with flaps (Viton®, Vulkolan and Teflon®)

- Fixed speed of the rotor : 10, 20, 30 rev./min.

- Variable speed of the rotor : 4 - 22 rev./min.

| Models | RVSC05 | RVSC10 | RVSC15 | RVSC20 | RVSC35 | RVSC80 |

|---|---|---|---|---|---|---|

| Capacity / liters/revolution | 5 | 9 | 14 | 20 | 38 | 78 |

| Flange section | 166x122 | 135x238 | 148x276 | 196x337 | 240x470 | 284x569 |

| Speed of the rotary valve rev./min. | Flow according to the associated load factor | ||

|---|---|---|---|

| Very fluid | Not very fluid | Not fluid | |

| 10 | 90% | 85% | 80% |

| 20 | 80% | 75% | 70% |

| 30 | 70% | 65% | 60% |

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Bulk truck loading

Processed powder: polypropylene - Bulk truck loading - This powder handling line is designed to feed granules into trucks at a high rate of 25 t/h. The production requirement is to create neither...Chemical

Loading silos with sugar

Processed materials: crystal sugar - Loading silos with sugar - A container tipper is used to feed the high pressure pneumatic conveying network to feed 2 silos of 50 tons.Food and Animal Feed