Description

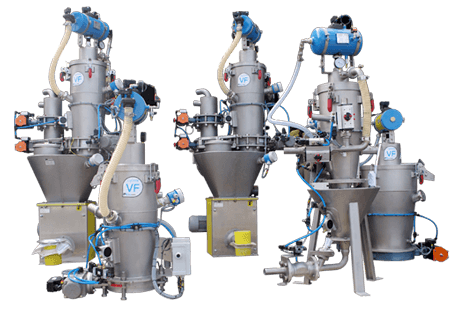

Dense phase vacuum conveying with detached filter - Continuous recovery of sucked powders for product reuse

In most of our standard dense phase conveying systems, a separating cyclone (offset filter) is coupled with a pneumatic conveying cyclone. The separating cyclone is fitted with a nozzle for collecting aspirated fines for continuous recyle within the industrial process.

Efficient flow rate is achieved by using a separating filter which enables the process to reduce the filter cleaning cycles (by 10% of the cycle time on average).

|

Image

|

Main functions: 1 - Cyclonic: air/product separation 2 - Storage: recapture of the material, preservation of volume expansion 3 - Finishes: separation and protection of the vacuum element 4 - Recycling the fines: fines recovery in a dedicated hopper for feeding back into the process. |

-

Rate4

-

Fragile material4

-

Fragile material4

Equipment advantages

- Minimized product loss: reintroduction of the fines into the process.

- Designs for harsh environments: loading of reactors in hazardous areas and protection of the filter against vapors, gases and dust (hazardous area classifications).

- High rate process: optimization via cyclone design and efficiency, reduction of pressure losses, continuous unloading.

- Difficult material conveying: protection of the filtering system, no clogging in the filter

Media

View our equipment in videos

Pneumatic vacuum conveying systems - Powders Pumps - PALAMATIC PROCESS

Vacuum transfer in dense phase for all types of powders and bulk materials

Apple : https://itunes.apple.com/us/app/palam...

Android : https://play.google.com/store/apps/de... http://www.palamaticprocess.com/powde...

Flow rate from 5 to 10.000 l/h.

Steel, 304 and 316L stainless steel construction

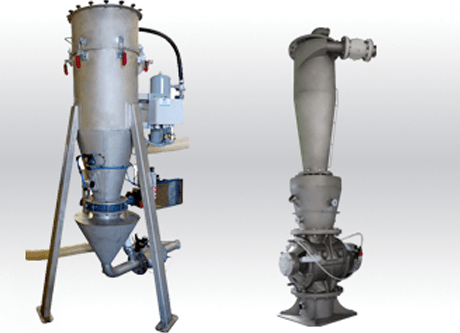

The new generation powder pumps developed by the PALAMATIC design office. Provides for dense vacuum transfer and prevents material deterioration continuously and confined in your production processes. Particularly suited to difficult materials (poor flow, fragility, abrasiveness, or explosive materials), this cyclone is easily installed in your environment with unlimited extension options. Suction from several feed points and / or feeding several points in your process. Coupled with weighing systems, it provides for weight-controlled introduction of raw materials. Also provides feeding a pressurized reactor vessel and feeding materials without added air.

3 functions : 1/ Transportation 2/ Dosing 3/ Weighing

Range of vacuum pneumatic conveying systems - Powder pumps - PALAMATIC PROCESS

RANGE OF VACUUM CONVEYING SYSTEMS

http://www.palamaticprocess.com/powde...

The new generation powder pumps developed by the PALAMATIC design office. Provides for dense vacuum transfer and prevents material deterioration continuously and confined in your production processes. Particularly suited to difficult materials (poor flow, fragility, abrasiveness, or explosive materials), this cyclone is easily installed in your environment with unlimited extension options. Suction from several feed points and / or feeding several points in your process. Coupled with weighing systems, it provides for weight-controlled introduction of raw materials. Also provides feeding a pressurized reactor vessel and feeding materials without added air.

The powder pumps are ideal for feeding :

- dust-laying (Triblender Silverson)

- mixers

- tanks

- reactor...

Visualisez nos équipements en réalité augmentée :

Apple : https://itunes.apple.com/us/app/palam...

Android : https://play.google.com/store/apps/de...

Pressure phase pneumatic conveying loading line with integrated dosing - PALAMATIC PROCESS

DILUTE PHASE PNEUMATIC CONVEYING WITH BOOSTER

http://www.palamaticprocess.com/powde...

This pneumatic conveyor in dilute phase, generally thrust, allows to carry pulverulent products at high throughput rate along important distances (not fragile products). This pneumatic conveyor in dilute phase by thrust lies in the use of wheel feeders (rotary valves) allowing to introduce measured doses of product in the piping. Regular application of pneumatic conveyor in dilute phase by thrust: silos emptying and silo filling.

Apple : https://itunes.apple.com/us/app/palam...

Android : https://play.google.com/store/apps/de...

Skid for reactors feeding by doses - PALAMATIC PROCESS

VACUUM PNEUMATIC CONVEYING SYSTEMS - POWDER PUMPS

http://www.palamaticprocess.com/powde...

3 functions : 1/ Transportation 2/ Dosing 3/ Weighing Flow rate from 5 to 10.000 l/h.

Steel, 304 and 316L stainless steel construction, Atex

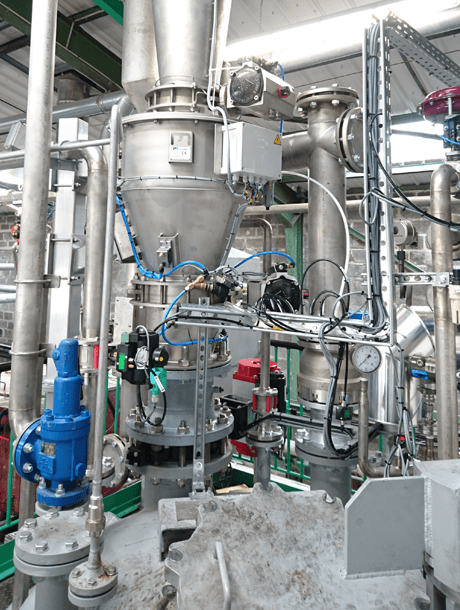

PALAMATIC offers the vacuum transport system V-Flow running on a dense phase principle.

The product is sucked through a vacuum pump (electric or pneumatic) to a arrival cyclone (cyclo-filter) with tangential arrival (cylindrical). The product is sucked through a pneumatic conveyor gearbox installed at the point of withdrawal (no rotary valve) until the vacuum cyclone that is equipped with filters of small sizes to separate the air from the product. The vacuum cyclone is equipped with a butterfly valve (or other if the process requires) and a level probe allowing the emptying at regular intervals.

The rates obtained by this type of powder pumps are between 5 and 10 000 litres per hour with low energy consumption and extremely simple maintenance.

The other advantage of this powder system is the ease of the implementation of the weight control.

The cyclone vacuum may be located on loading cells allowing the suction and feeding of the conveyed product.

Visualisez nos équipements en réalité augmentée :

Apple : https://itunes.apple.com/us/app/palam...

Android : https://play.google.com/store/apps/de...

Mobil unit - Suction tube for drum and sack discharging

DRUM DISCHARGING SYSTEM - DRUMFLOW® 01 - SUCTION TUBE

The DrumFlow® 01 system was designed by Palamatic Process to perform drum discharging operations through a suction tube. The material contained in the drum will be incorporated in the production process thanks to vacuum suction technology. The emptying of the drums is carried out directly on pallet and without specific handling.

The suction tube allows the suction of the powder by manual operation. This suction tube is ideal for emptying drums.

The vacuum is directly carried out in the drum from the vacuum cyclone.

Transfert pneumatique - Cyclone d'aspiration - Palamatic Process

Débit de 5 à 10 000 l./h. Fabrication acier, inox 304, inox 316 L

http://www.palamaticprocess.fr/machin...

Apple : https://itunes.apple.com/us/app/palam...

Google : https://play.google.com/store/apps/de...

Il permet un transfert dense sous vide et évite la détérioration du produit de façon continue et confinée dans vos process de fabrication. Particulièrement adapté aux produits difficiles (mauvais écoulement, fragilité, abrasivité ou explosivité du produit), ce cyclone s'implante très facilement dans votre environnement avec possibilité d'extension sans limite. L'aspiration se fait à partir de plusieurs points d'alimentation et/ou alimentation de plusieurs points de votre process. Couplé à des systèmes de pesées, il permet l'introduction contrôlée en poids des matières premières. L'alimentation de réacteurs sous pression et l'alimentation du produit sans apport d'air est alors possible.

Dense phase pneumatic conveying

Vacuum transfer in dense phase for all types of powders and bulk materials

Apple : https://itunes.apple.com/us/app/palam...

Android : https://play.google.com/store/apps/de... https://www.palamaticprocess.com/bulk...

Flow rate from 5 to 10.000 l/h.

Steel, 304 and 316L stainless steel construction

The new generation powder pumps developed by the PALAMATIC design office. Provides for dense vacuum transfer and prevents material deterioration continuously and confined in your production processes. Particularly suited to difficult materials (poor flow, fragility, abrasiveness, or explosive materials), this cyclone is easily installed in your environment with unlimited extension options. Suction from several feed points and / or feeding several points in your process. Coupled with weighing systems, it provides for weight-controlled introduction of raw materials. Also provides feeding a pressurized reactor vessel and feeding materials without added air.

3 functions : 1/ Transportation 2/ Dosing 3/ Weighing

View our equipment in photos

Pneumatic conveying with detached filter

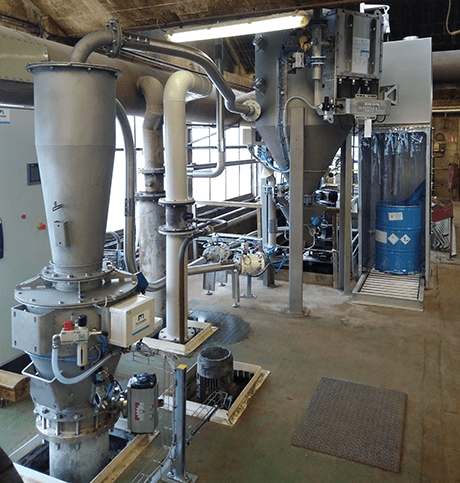

Multi-drain points for a coating reactor. Pneumatic conveyor for resins, polymers, talc and silicas.

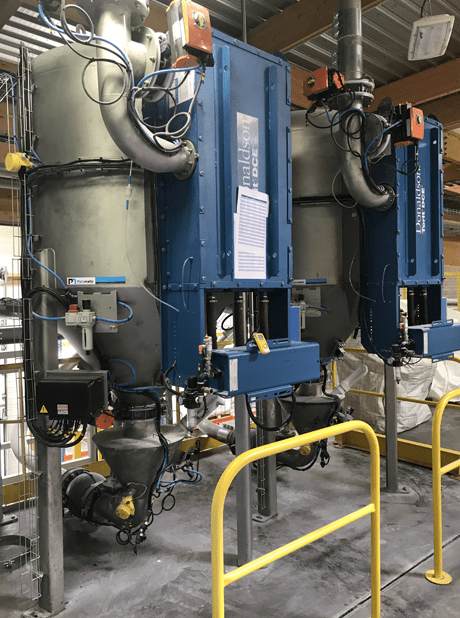

Detached filter on pneumatic conveying

Automatic loading of reactors with raw materials and dosing system.

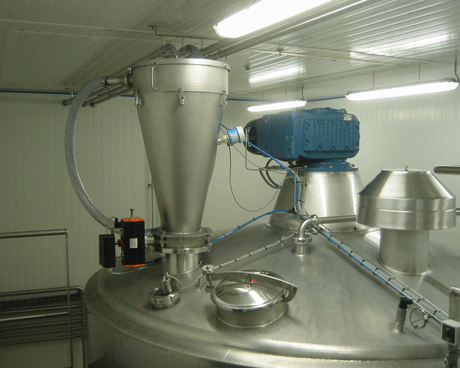

Salt and sugar processing line

High throughput processes: optimization of cyclonic efficiency, reduction of pressure drops, continuous discharging.

Dense phase vacuum pneumatic conveying

Implementation in difficult environments: supply of reactors in explosive areas (ATEX).

Feeding of an extruder with polymer

Handling of difficult materials: protection of the filtration system, no clogging of the filter.

Chemical powder pneumatic conveying

Granules, metallic powders or fats, the VFlow® range ensures the conveying of more than 95% of existing powdery materials.

Hopper feeding with pneumatic conveying

Pneumatic conveying performs several functions, thus minimizing the number of equipment required.

Powder and bulk material pneumatic conveyor

Installation of a big bag emptying station for feeding 3 storage silos in vacuumed pneumatic conveying.

The station is mounted on load cells and is fitted with a conveying screw allowing the material to be dosed.

Pneumatic vacuum conveyor of powders and bulk materials

Bulk materials pneumatic conveying at the outlet of an atomization tower.

Detached filter on pneumatic conveyor

VFlow® with detached filter. The separator cyclone is coupled to the pneumatic conveying cyclone.

Pneumatic conveying system for big bag filling

Pneumatic conveyor on a big bag filler.

Bulk materials pneumatic conveying

Pneumatic solutions for bulk conveying applications.

Container discharging with pneumatic conveying

Integrated equipment:

- Pneumatic conveying - Dense phase vacuum conveying - Detached filter

- Dense phase vacuum pneumatic conveying VF05

Detached filter pneumatic conveyor

- Securing industrial production lines

- Improvement of operators' working conditions, cleanliness and productivity.

Pneumatic conveyor with detached filter - Manufacture of adhesives

Feeding of raw material processes (granules, food powders...).

Detached filter on pneumatic conveyor

Pneumatic conveying of dust from filtration systems.

Features

Technical specification

| Models | Rate in m³ / h | Piping Ø in mm |

Filtering surface in m² |

Cyclone outlet Ø in mm |

Cyclone height in mm |

|---|---|---|---|---|---|

| VF DEP 02 | 2 | 50 | 5 | 200 | 600 |

| VF DEP 04 | 4 | 65 | 8 | 200 | 780 |

| VF DEP 06 | 6 | 80 | 12 | 200 | 1,431 |

| VF DEP 08 | 8 | 100 | 18 | 250 | 1,850 |

| VF DEP 10 | 10 | 125 | 26 | 300 | 2,200 |

Particle sizes: 5 - 3 mm

Average level of vacuum: 500 mbar absolute

Cyclonic efficiency:> 99.5%

Manufacturing materials: 304L stainless steel, 316L stainless steel

Available finishes: outside microblasting, inside electropolishing, inside mirror polishing

Filtering media: PTFE, antistatic PTFE , FDA certified

ATEX certification : zone II 1,2,3 GD (less than 3 mJ EMI).

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Reactors loading

Processed bulk material: lithium fluoride - Reactor loading - High performance pneumatic vacuum conveying with dosing container for incorporation into pressurized reactors. Our customer, a Chinese...Chemical

Drum unloading enclosure

Processed product: Triuranium octoxide (U3O8) – Drum tipping station - The installation concerns the installation of a production system that empties, transfers and doses drums of a toxic product...Energy