Description

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products. Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is around a d50 of 80 microns. Results can vary depending on the material, rates, feed, etc.

Made from mild steel, stainless steel 304L or 316L

4 models according to required feed rates and capacities: 160, 315, 500 and 630

Industrial mill range

The Poly-Mill industrial grinder is the ideal solution for milling a wide range of bulk products. Each milling system requires a specific solution according to the expected particle size range. The Poly-Mill grinder can be fitted with several easily interchangeable milling tools to adapt to the specific needs of each application. Custom designs for CIP milling requirements and turn-key solutions available with our experienced engineering staff capabilities.

| Models | UM160 | UM315 | UM500 | UM630 |

|---|---|---|---|---|

| Power in kW | 5.5 | 18.5 | 37 | 75 |

| Theorical flow in m³/hr. | 250 | 1,000 | 2,000 | 3,600 |

| Scale factor | 0.25 | 1 | 2 | 3 |

* These flow rates are given on a production of icing sugar with an output size < to 130µm for 98%

FOOD PROCESSING APPLICATION

Equipment advantages

- Design configuration according to available space

- Easy access to grinding chamber via swing-away door and interchangeable grinding media

- Reinforced feed inlet design ensuring high rotation velocity and dust tight sealing

- Ultra fine particle size milling

- Adjustable quantities of pin rows for more or less impact surfaces

Media

View our equipment in videos

4 models of UM Palamatic process mills

Range of mills for powder products

View our equipment in photos

Industrial crusher machine Palamatic Process

Industrial grinding machine by Palamatic Process.

Industrial mill Palamatic Process

The industrial mill is the ideal solution for crushing bulk material and powdery products.

Features

Technical specification

The Poly-Mill grinding mill offers great grinding reliability over long production periods. Designed with very high resistance mechanics, it offers not only efficiency and safety of use, but also ease of maintenance and cleaning. The risks of cross contaminations are almost nul.

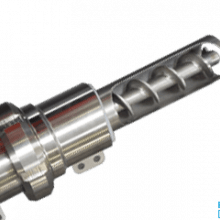

Milling tools:

- Pins, with or without screen

- Mobile or fixed hammers

- Paddles

- Knives

Results focus: fine, medium or coarse grinding, crushing, grinding, fiber separation for all types of bulk materials to be processed.

Model (1) UM-315 UM-500 UM-630

|

Model (1) |

|

UM-315 |

UM-500 |

UM-630 |

|---|---|---|---|---|

|

Type of milling |

||||

|

Paddles |

Kw |

18.5 |

37 |

75 |

|

Pins |

Kw |

18.5 |

37 |

75 |

|

Standard speed |

||||

|

Paddles |

t/min |

7,300 |

4,600 |

3,500 |

|

Pins |

t/min |

8,150 |

5,900 |

4,900 |

|

Motor |

t/min |

2,880 |

1,440 |

1,440 |

|

Weight (2) |

KGS. |

315 |

650 |

1,200 |

|

Flow coefficient |

|

1 |

2 |

3.2 |

Dimensions :

| Models | A | B | C | D | ØD1 | ØD2 | E | F | G | KW | Max Air Volume m³/h. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UM 160 | 625 | 645 | 714 | 1,340 | 76 | 165 | 660 | 1,210 | 1,115 | 5.5 | 500 |

| UM 315 | 910 | 1,035 | 614 | 1,524 | 168 | 280 | 910 | 1,470 | 1,105 | 18.5 | 1,500 |

| UM 500 | 1,185 | 1,035 | 614 | 1,800 | 219 | 336 | 910 | 1,470 | 1,280 | 37 | 3,200 |

| UM 630 | 1,450 | 1,335 | 614 | 2,065 | 219 | 336 | 1,215 | 2,620 | 1,462 | 75 | 5,000 |

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Line for biscuit factory

Processed powder: Crystal sugar - Line for biscuit factory - Food manufacturer that specializes in biscuits, chocolate and cocoa. The customer's process requirements involved the milling of granulated...Food and Animal Feed

Icing sugar line

Processed powder: starch and granulated sugar - Icing sugar line - French sugar cooperative company - Supply and commissioning of a set of machines for the production of icing sugar and starch to feed...Food and Animal Feed

Seaweed preparation

Processed product: seaweed - Seaweed preparation - Manufacturer of organic raw material for cosmetics.Fine chemical

Discharge, Feed and Grinding Line

Processed bulk material: Lysine - Grinding Line - Facility for one of the world's leading animal nutrition companies.Food and Animal Feed

Conveying and grinding line

Processed powder: supplemental milk powder - Pneumatic conveying and grinding line - This company was looking to reduce the granulometry of its final product with a homogeneous particle size spectrum.Food and Animal Feed

Disinfectant packaging

Processed powders: sodium carbonate, acid... - Disinfectant packaging - Production line of cleaning products for the maintenance of livestock buildings.Chemical

Industrial powder grinding

Processed bulk material: calcium formate - Industrial powder grinding - The objective of the pin grinding plant is to make the granulation of the 2 raw materials homogeneous and reliable before their...Minerals and building

Conditioning in big bags and sachets

Processed material: potato flakes - Conditioning in big bags and sachets - The objective is to reduce the potato flakes in powder in order to increase the density of the productFood and Animal Feed

Injection of sodium bicarbonate

Bulk material processed: sodium bicarbonate - Injection of sodium bicarbonate - The Palamatic Process pin mill plays an important role since the grain size has a direct impact on the efficiency of the...Water and smoke

Cosmetic foundation production line

Processed powders: silica and iron oxide - Foundation manufacturing line - The aim of the installation is the mixing and homogenization of the different ingredients.Fine chemical

Recycling of milk powder by micronization

Processed powder: dairy product flakes, PSD 400 to 500 µm - Recycling of milk powder by micronization - The installation consists of the dosing, transfer, grinding and reconditioning of the milled...Food and Animal Feed

Preparation of food mixtures

Processed product: crystal sugar/icing sugar - Preparation of food mixtures - This icing sugar production unit is composed of a big bag loader, a dosing screw, a pin mill, a buffer hopper and a bag...Food and Animal Feed

Sugar grinding unit

Processed powders: icing sugar from white granulated sugar and starch - Sugar milling unit - The installation consists of feeding the mill with granulated sugar and then packaging the resulting icing...Food and Animal Feed

Grinding and packaging of finished products

Processed products: dried insects - Grinding and packaging of finished products - Workshop for processing and packaging products for the animal nutrition sector.Food and Animal Feed