Description

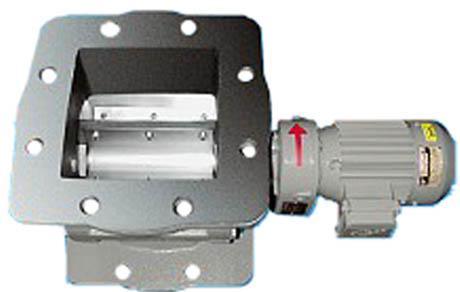

Dust lock rotary airlock valve - Dedusting under cyclone or filter

To regulate and dose conveyed material

The dust control rotary airlock valve is suitable for simple and less demanding industrial applications where its main function is that of a lock.

The dust control rotary airlock valve is specifically designed for gravity discharge and filter applications. The universal flanges on both sides of the valve are drilled to PN 10 and suitable for both round and square flanges.

Operating mode

The dust control airlock has a very large inlet and a direct drive, providing ample torque to the rotor, which has 6 replaceable and adjustable polyurethane blades. An optional steel fixed bladed rotor is also available.

The standard drive is a Nord helical geared motor, type SK01-F-71L/4, 0.37 kW, IP 55, isol. F, giving 27 rpm at 50 Hz and 32.4 rpm at 60 Hz. Suitable for 230/400V 50 Hz and 278/480V 60 Hz.

The standard model is suitable for handling bulk materials up to a temperature of 70°C and a maximum pressure differential of 0.5 bar.

The valve is pressure shock resistant up to 10 bar g pressure.

Equipment advantages

- Minimum air leakage

- Barrier to flame

- Polyurethane rotor blades

- Suitable for both round and square counter flanges

- Versions conforming to ATEX 94/9/EC available, specifications up to Group II Category 1D

Media

View our equipment in photos

Rotary valve - Dust collection

The dust control rotary airlock valve is used to reintroduce fines into the conveying line.

The independent dust collection system for pulverulent charged air with reintroduction of fines (no loss and management of suctioned dust): talc, magnesium, Mica, CaCO3.

Rotary valve under dust collector

The dust control rotary airlock valve is flanged on a bulk bag discharging station with reintroduction of fines in the process.

Process ciment et fumées de silice

Aspiration ciment et fumées de silice sur station de vidange de big bags.

Rotary valve - Dust collection Palamatic Process

The rotary dust collection airlock valve is used to regulate and measure the conveyed bulk material.

Rotary valve

The rotary airlock valve has a very large inlet for the operation of the rotor with 6 flexible polyurethane blades that are adjustable and interchangeable.

Rotary valve Palamatic Process

Dosing of bulk materials for the supply of the pneumatic conveying.

Drop through rotary airlock feeder

For the extraction and dosing of the powdered product.

Drop through rotary airlock feeder Palamatic Process

Flow rate from 2.2 to 19.5 litres/rev.

Features

Technical specification

The inlet of the valve is square, therefore accommodating both round and square outlets from the vessel that has to be discharged. The steep angle of the inlet to the rotor reduces the chance of material bridging.

The outlet from the valve is round for discharge into either a round or square connection.

Dimensions

| Type | Liters/rev. |

ØA |

A | ØB | ØC | C | D | E | F | G | X | RR | SS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 6 | 200 | 200 | 295 | 340 | 320 | 8 x Ø23 | 14 | 310 | 155 | 22.5° | 465 | 176 |

| 250 | 8,5 | 250 | 250 | 350 | 406 | 370 | 12 x Ø23 | 15 | 325 | 162.5 | 30° | 485 | 196 |