Description

Containment and cleanliness of the process

Industrial dust collectors are used for dust collection or vacuum applications for industrial production lines involving raw ingredients and bulk materials handling. The built-in industrial dust collector can be flanged directly to equipment.

The built-in industrial dust collector is modular and integrates maximum operating and maintenance safety.

The built-in dust collector is ideally suited for processing powders with high dust emission. It is generally implanted under silos (to prevent explosions due to dust concentration), reception hoppers of pneumatic conveying.

The operator then has a clean working environment protected from all risks of contamination. Our Palamatic Process equipment is manufactured according to the standards in force in 2006/42/CE.

-

Rate

-

Efficiency

-

Ease of integration

Possible configurations

Vertical

Horizontal

Equipment advantages

- High efficiency filtration

- Available with or without fan

- Easy maintenance, convenient maintenance height

- Replacement of filter elements without tools

- Long service life

- Low maintenance costs

- Hygienic operation

- Working in complete safety

Media

View our equipment in photos

Dust collector on hopper

Installation of a dust collector on a storage hopper for discharging dusty bulk materials.

Dust-collection on sack dumping unit fed with a sack manipulator

Double station for emptying crystal sugar bags and feeding sugar melter.

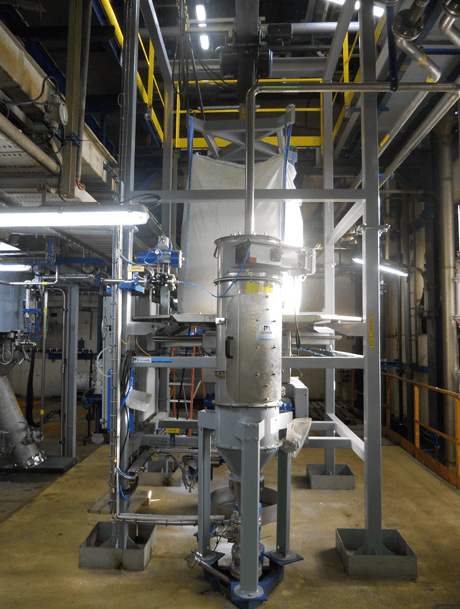

Built-in dust collection unit

Workshop for emptying bags for crusher feeding.

Dust collection on silo

Discharge, pneumatic conveying and dosing.

Dust collector bulk handling

Deconditioning of big bags of iron sulphates for silo repacking.

Industrial dust collection

Industrial dust collection consists in eliminating dust emissions by collecting them on the equipment.

Bulk materials handling dust collection

The dust collector keeps the working atmosphere clean for the operator's safety.

Built-in industrial collector on production line involving raw ingredients

Industrial air dust removal is carried out according to the principles of vacuum and filtration. This is used to control pollution and to have a clean working atmosphere.

Silo dust collection powder process

The silos are filled with cement for a building industry. The operator's environment is healthy thanks to the installation of a dust extraction system.

Bulk handling storage filtering

In the case of explosive dust, dust collection equipment meeting the ATEX directive will be provided.

Industrial filtration Palamatic Process

Palamatic Process designs and manufactures a wide range of filters, pumps and powder handling solutions for industry.

Bulk powder dust collection

Atex dust collector with vacuum and dust filtration (powders, raw ingredients and bulk products).

Manual bag dump station with dust collector

Industrial dust collection system for emptying titanium dioxide bags.

Dust filtering bulk handling equipment

Cartridge filter for powder coating.

Dust collector on bag dump station

Industrial dust collection on manual bag dump station fitted with a bag compactor.

Industrial dust filtration

The built-in dust collector is designed for the filtration and relative separation of medium, fine and impalpable dust.

Dust collector built in a big bag discharge station

Discharge and pneumatic conveying of feed additives to storage silos.

Food process dust filtration

Automatic big bag filling line for sugar packing.

Pneumatic vacuum transfer with detached filtration

The powder process is designed to load two melters from two big bag discharge stations.