Description

Automatic bag dump station - MINISLIT® - Automatic opening without any adjustment

The Minislit® automatic bag dump station is an industrial bag cutter that uses a ribbon saw system to cut the sack on three sides and prevent shredding of the package material. This bag splitter employs patented disc inversion mechanisms to grab the sack material and flip it over for full and efficient discharge of the contents.

Designed to open bags of dry granluar, bulk solids and powders, the Minislit® automated bag opening equipment is available with a belt cutting system. Suitable for multiple applications including aggregates and food, the integrated parts of the Minislit® bag cutting device can be cleaned manually or mechanically using the "Cleaning In Place" (CIP) option. This optional CIP design provides a quick and complete wash down.

The Minislit® bag splitter machine offers a bag opening rate of 4 to 8 bags/min.

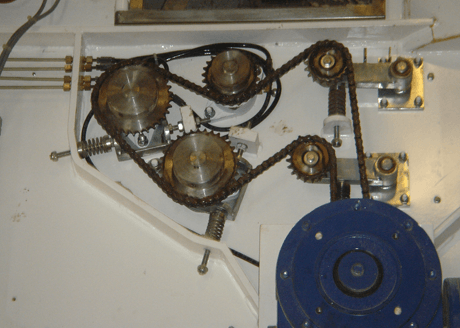

To minimize wear and tear of this industrial bag splitter, the mechanical gears and guiding components are located externally, offering versatility in material unloading operations and easy access for maintenance of parts.

The MiniSlit® equipment can be integrated into an automatic bag opening process line such as our DePalSack® line.

-

Rate4

-

Overall dimensions5

-

Hygiene5

Operation procedure:

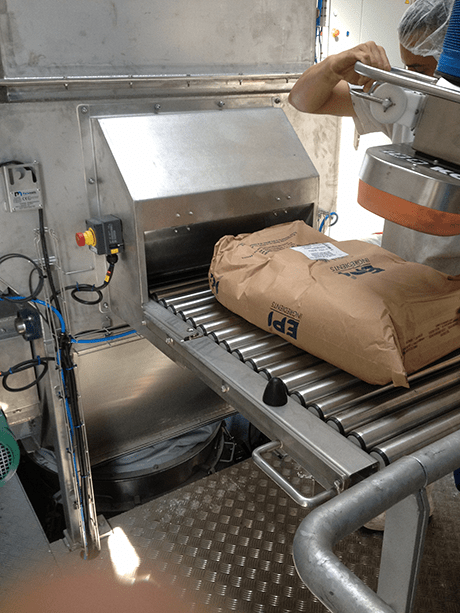

1. Deposit of the bag on a roller conveyor, positioned laterally to the bag dump station, for its introduction into the body of the machine on the screen provided for this purpose

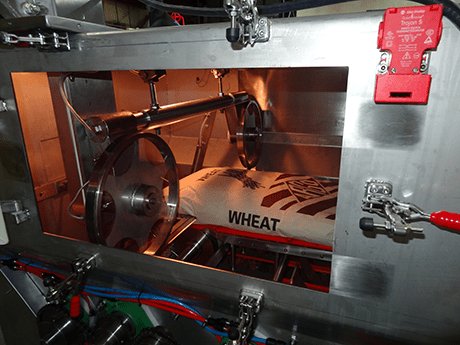

2. The presence of the bag is detected by the sensor that controls the cutting system

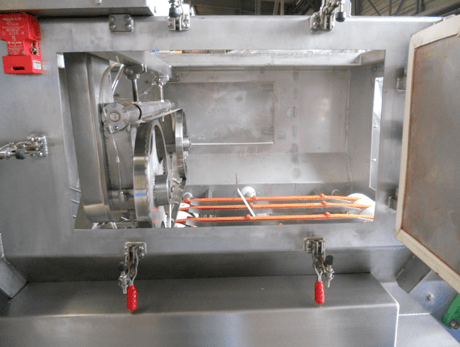

3. The blade cuts the bag and the lower part is grasped by the inversion discs for complete emptying

4. When the sensor is deactivated, the blade moves up to the rest position so as not to cut the bag in half

5. The bag is directed towards the bag compactor through a helical screw and the machine is ready to receive the next bag

Equipment advantages

- Automatic saw cutting system

- Bag manipulator and belt conveyor

- Screw compactor for waste package evacuation and dust containment

- External gearboxes for less wear and tear

Media

View our equipment in videos

Automatic bag dump station - MiniSlit®

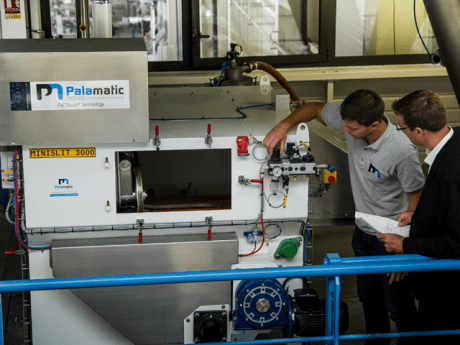

Designed to open bags of powders and bulk materials, the automatic Minislit® 3000 bag discharging station is available with a belt cutting system.

Automatic sack discharging - Minislit

Automatic sack discharging - MiniSlit®

Automatic sack station MiniSlit®

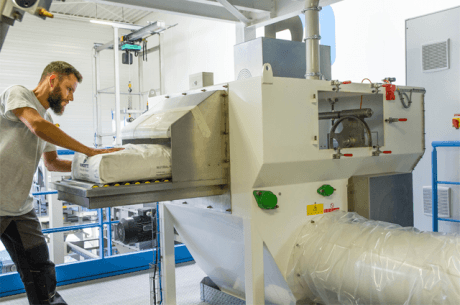

The MiniSlit® machine is equipped with a bag manipulator and a belt conveyor.

View our equipment in photos

Roller conveyor Minislit®

The Minislit® system is equipped with a roller conveyor.

Minislit® sack discharging - Palamatic Process Inc.

The Minislit® automatic bag emptying station ensures maximum emptying rate.

Minislit® Palamatic Process Inc.

Minislit® is an automatic bag emptying machine from Palamatic Process Inc.

Automatic sack discharging

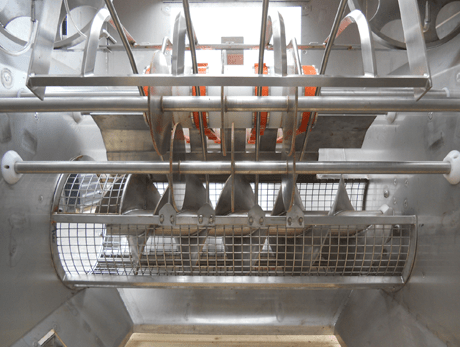

Inverting disc that facilitates automatic bag cutting.

Automatic bag dump station - minislit®

Bag discharging station for bulk materials handling applications.

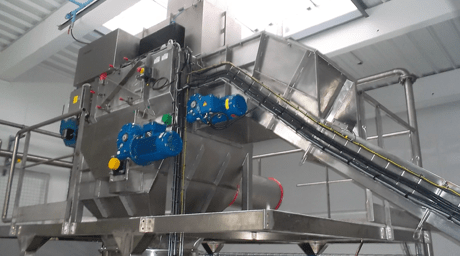

Automatic bag dump station with compactor

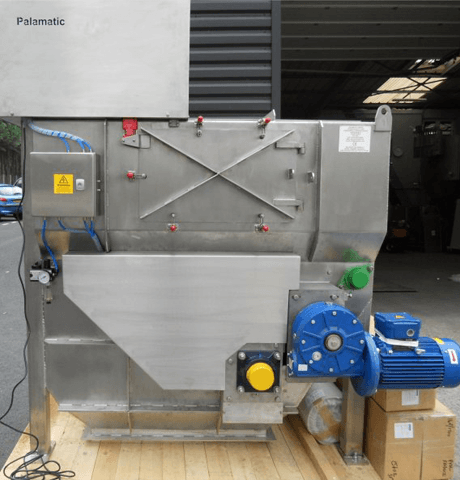

The screw compactor ensures the removal of empty bags and the reduction of dust emissions.

Automatic bag dump palamatic process

The Minislit® is part of our test station for easy testing with all types of bags.

Minislit with bag compactor

Designed to open bags of powders, bulk materials, bulk solids, raw ingredients, the automatic bag discharging Minislit® is available with a strip cutting system.

Automatic bag discharging - Minislit

The Minislit® automatic bag discharger is used to open and discharge bags made of single or multi-layer paper, polyethylene, paper with polyethylene sheath and woven plastic with or without polyethylene sheath.

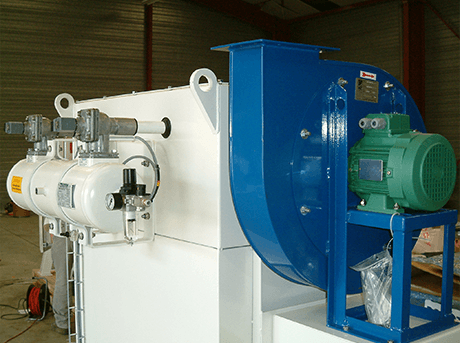

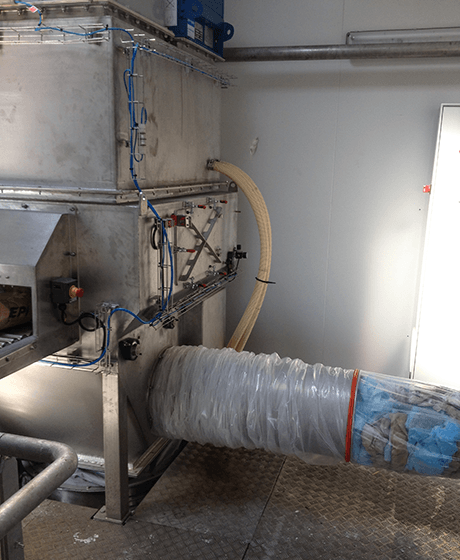

Automatic sack discharger blower

Blower system on Minislit® automatic bag discharger.

Minislit® - Palamatic Process

The mechanical drive and guide parts are installed outdoors, which protects them from wear and tear and allows very abrasive bulk materials to be discharged.

Automatic sack discharging

This gravity conveyor is fitted with 10 rollers that take the bags to the drive belts of the bag opening machine.

Automatic sugar sack discharging

The automatic bag dump station is connected to the pneumatic conveying.

Powder processing automatic sack opening

Pneumatic ribbon cutting system available in different options: carbon steel, stainless steel or diamond coated for applications with abrasive products.

Minislit interior view

Principle of operation of the cutting system.

Automatic bag opening - Minislit

Automatic bag discharger for bulk solid materials, raw materials, bulk solids.

Bulk materials handling automatic sack discharging

Inclined belt for feeding the bag discharger.

Internal view of the Minislit®

The belt conveyor transports the bag directly to the ribbon-saw cutting system.

Automatic sack opening Palamatic Process

The automatic bag dump station is equipped with a belt conveyor and a bag manipulator.

Features

Technical specification

| Capacity | 15 to 50 kg/sack |

|---|---|

| Manufacturing materials | Painted steel, 304L stainless steel, 316L stainless steel |

| Electrical power | 5.5 kW |

| Pneumatic consumption | 3 Nm³/h. |

| Dust removal rate | 600 m³/h. |

The special ribbon strip cutting system avoids shredding the package material and allows the bags to be cut on 3 sides. The principle of turning and emptying the bags provides full discharge of the material contents. It is particularly suitable for food and chemical industries, as well as the powder paint industry.

Like all PALAMATIC PROCESS bag dump stations, its design facilitates cleaning and maintenance with the minimum number of retention areas. The mechanical drive and guide parts are installed externally, which greatly reduces wear and tear. Our automated high rate sack tip equipment / automated bag cutting device is designed for high production process requirements utilizing small batch packaged ingredients.

| Electrical powers | |

|---|---|

| Bag infeed conveyor (optional): | 1,5 kW |

| Cutting head drive motor: | 1,5 kW |

| Compactor and internal conveyor: | 2,2 kW |

| Fan motor (optional): | 1,5 kW |

| Vibrating motor (optional): | 0,25 kW |

Dimensions

Example of implementation

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Preparation of instant dairy beverage

Processed powders: milk powder and sugar - Preparation of instant dairy drinks - Agribusiness group in the Island of Reunion is a leading supplier of dairy products within their target markets: fresh...Food and Animal Feed

Compound line

Processed powder: polypropylene - Compound line - Installation of an automatic bag emptying system for polypropylene balls with a flow rate of 100 bags per hour.Chemical

Plastic extrusion

Processed powder: polypropylene - Plastic extrusion - Installation of 2 automatic bag opening machines allowing to reintroduce in the process line productions packed in 25 kg bags at a capacity of 12t...Chemical

Manufacturing line for petfood industry

Processed Powders: Soy Flour, Brewer Yeast, Corn Starch, Dried Whey... - Manufacturing line for petfood industry - Manufacturering of dry and liquid flavor enhancers for the pet food industryFood and Animal Feed