Description

Vibratory sieve on pneumatic conveying line - optimization of flow rates without pressure loss

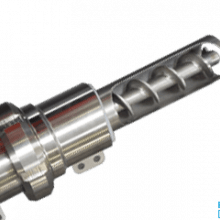

The vibratory flat deck screener can be used for inline pneumatic conveying to guarantee a high-quality final product. The inline pneumatic screening equipment can be used with flexible and ergonomic feeding devices.

The robust and air-tight construction of the inline pneumatic screener prevents the loss of good material and pressure.

With its enclosed design low pressure loss (0.213 psi), the Palamatic Process GSC sieve is ideal for being set up on pneumatic conveying lines.

The bulk material is fed via the top flange connection facing the mesh screen sieve. This configuration improves the sieving thanks to the impact of the material and vibrating frequency by the offset motor. The side discharge port can be controlled and utilized with the integration of control valves.

The inline vibratory sieve can be used on both dense phase pressure or vacuum conveying system.

-

Rate4

-

Hygiene5

-

Ease of integration5

Diagram of dense phase vacuum conveying system

Diagram of dense phase pressure conveying system

Equipment advantages

- Ground installation

- Compact size

- Optimized flow rate

- No material loss

Media

View our equipment in videos

Vibratory sifter on pneumatic conveying line

Vibratory sifter fed by a screw feeder

View our equipment in photos

Vibratory sifter on pneumatic conveying line

In-line screening on pneumatic conveying ensures product quality with a high degree of feeding flexibility and ergonomics.

Bulk materials and powder industrial sifting

Palamatic Process sifter for control and safety screening, for high throughput of powdery and bulk materials.

Bulk materials vibratory sifting under hopper

In-line vibratory screener under bulk and powder storage hopper.

Titanium dioxide screening

Titanium dioxide screening system fed by a VFlow® vacuumed pneumatic conveying system.

Vibratory sifter on pneumatic conveying line

Bulk materials sifting

The safety screen is vibrated by electric motors and enables the grain size of a bulk material flow to be controlled to extract foreign bodies that may be present in dry bulk products.

Features

Technical specification

| Useful Ø | 912 mm |

|---|---|

| Height | 994 mm |

| Weight | 150 kg |

| Electrical power | 2*0.16 kW |

| Distance between input and output flange | 2.5 t./h. |

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Infant milk powder line

Processed bulk solids: milk powder - Infant milk powder line - This subsidiary company from one of the first milk group in the world, devellops a wide range of functionals and nutritionals milk...Food and Animal Feed

Preparation of instant dairy beverage

Processed powders: milk powder and sugar - Preparation of instant dairy drinks - Agribusiness group in the Island of Reunion is a leading supplier of dairy products within their target markets: fresh...Food and Animal Feed