Treated powders: ammonium perchlorate

Secure automation of the emptying of drums of ammonium perchlorate in the aerospace industry with the DrumBot 300

Context and issues

Our client, a major player in the aerospace sector, uses ammonium perchlorate, an essential component of solid propellants. This raw material, which is highly reactive and sensitive, requires strict handling standards to guarantee operator safety and product integrity.

The aim was to replace a risky and restrictive manual process with an automated and contained solution, limiting any human exposure and improving the traceability of operations.

Solution implemented: DrumBot 300

Operational process

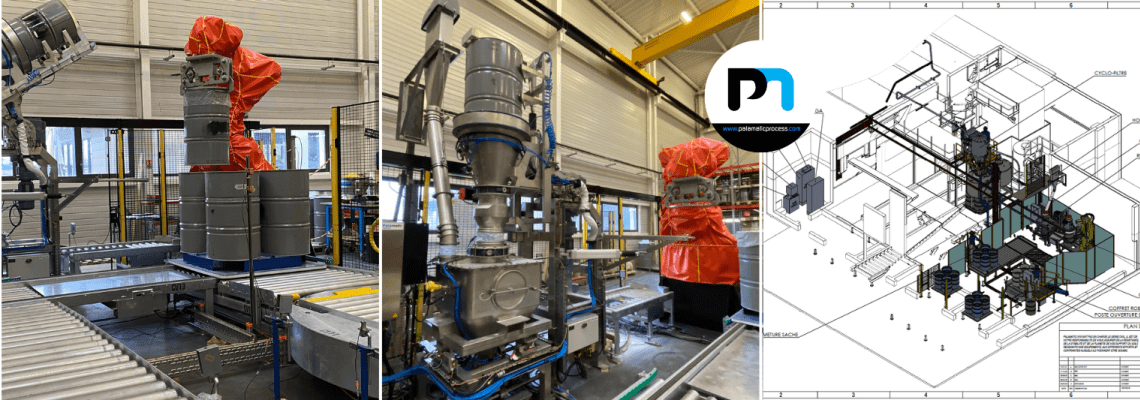

Palamatic Process has integrated the DrumBot 300, an automated drum emptying system combining a depalletising robot and a DrumFlow 04 hermetic emptying station

Automated drum feeding

- Forklift operators place pallets of full drums on a motorised conveyor.

- A detection system identifies each pallet and directs it to the DrumBot 300.

Robotic depalletisation and transfer

- The depalletisation robot picks up the drums directly according to a predefined palletisation plan.

- Each drum is then transferred to the DrumFlow 04 emptying station.

Hermetic emptying and containment

- The sealed capping system ensures total containment of the product.

- The drum is tilted 180°, allowing complete emptying without dispersion.

- The ammonium perchlorate is transferred under containment to the finishing process by a pneumatic transfer system in a semi-dense phase using Vflow technology.

Repositioning of emptied drums

- Once emptied, the drum is picked up by the robot and repositioned on an empty pallet.

- The emptied drums are then removed by forklift drivers for storage or reconditioning.

Optimised flow management

- Once the pallet of empty drums is full, it is automatically removed.

- A new pallet of full drums is introduced, ensuring a continuous and uninterrupted production cycle.

Benefits of the automated system

- Enhanced safety: Elimination of human handling, total containment of ammonium perchlorate.

- Reliability and precision: Precise depalletisation according to a defined plan, guaranteeing an optimal flow.

- Full automation: Process without intervention, except for the opening of drums.

- Improved traceability: Integration into the supervision system for real-time monitoring.

Conclusion

The integration of the DrumBot 300 has enabled the automation of the emptying of ammonium perchlorate drums, guaranteeing safety, efficiency and logistical gains. This solution illustrates Palamatic Process's ability to provide equipment adapted to the strictest requirements of the aerospace sector.