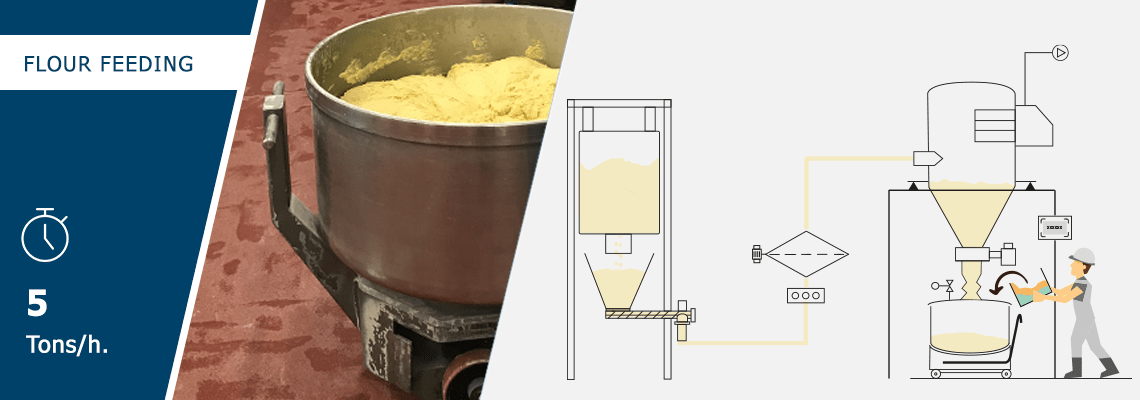

Mixer loading from silos of flour and other macro-ingredients

The production operator positions the kneading bowl under the false loading cover. The dosing system, using a feeder or dosing screw, handles the automatic dosing of macro ingredients. The rest of the ingredients are added manually by the operator.

- Automatic loading of macro ingredients

- Exact weighing of flour

- Vacuum conveying

- Hygienic connections

- Ease of use

Models

| BakeFlow1® 2 | BakeFlow1® 5 | BakeFlow1® 9 | |

|---|---|---|---|

| Production capacity in t/h. of dough |

1 | 2 | 5 |

| Macro- ingredients storage | Big bags or indoor or outdoor silo | Indoor or outdoor silo | Indoor or outdoor silo |

| Number of start zones | 1 to 2 | 1 to 2 | 1 to 4 |

| Hopper weighing volume | 300 liters | 600 liters | 900 liters |

| Dosing accuracy | 1% | 1% | 1% |

| Magnetic protection | Magnetic bars | Magnetic bars | Magnetic bars or optional ejector |

| Sieving | Vibrating screen | Centrifugal sieve | Centrifugal sieve |

| Number of filling zones | 1 to 4 | 2 to 4 | 2 to 8 |

| Kneading machine filling | Independent station with integrated dust collection | Integrated or independent station with integrated dust collection Option: multi-format bowl |

Integrated or independent station with integrated dust collection. Option: multi-format bowl |

The automated flour transfer line ensures fully automated and controlled loading of macro ingredients into bakery mixers.

The flour stored in sacks, big bags or silos is directly vacuum conveyed in masked time towards the separating filter cyclone. The pneumatic conveying technology offers remarkable hygiene vis-à-vis the emission of dust to the outside.

The cyclo-filter is equipped with a high efficiency filter and an automatic pneumatic unclogging system. The industrial quality of the filter media is well above average, which ensures absolute filtration power and a healthy atmosphere for working operators.

Due to the pneumatic transfer technology used the pipe network can reach extensive distances when necessary. The positioning of the flour stock can be more than 100m from the dough mixer loading area.

Mixer filling and dosing

The manufacturing operator positions his dough mixer directly under the flour weighing hopper. Once the bowl has been positioned, he can authorize loading by indicating the recipe on the control HMI specific to the zone.

The weighing scale positioned under the tank controls the rotary dosing valve. The weighing hopper's load cells control the rotary dosing valve. The frequency inverter controlled by this scale ensures dosing accuracy to 1%.

The BakeFlow1® flour loading line for bakery mixers is the simple, effective solution for drastically reducing the load-bearing capacity of production operators. In this version, mini and micro ingredients are added manually. The BakeFlow2® and BakeFlow3® stations provide additional automation for the most demanding requirements.

Depending on your flour requirements, the BakeFlow1® line is available in 3 standard models to match your production rates.

The aim of this line is to automatically load and feed these bakery mixers with the right amount of flour.

Additional options, such as in-line sieving or magnetic detection, are standard. Consult our powder handling experts for a quotation.

The automatic feeding of your ingredients is part of Palamatic Process's know-how…

Discover all our turnkey process lines in the food industry!

Discover the installations of our customers who use the BakeFlow®1 automatic mixer loading line.

All the equipment integrated into the BakeFlow®1 process line is available below.