Case studies - Minerals and building

Our knowledge of the cement and quarry sector ensures you a quality service and a technical solution adapted to your project.

For your cement plants, quarries, industrial plasters, glass factories, minerals and metals, we have the solution for your bulk materials handling line or industrial powder handling line.

Case studies with our customers

Decompacting cement big bags

Cement and plastering Minerals and building

Unloading big bags of carbonaceous rock

Quarry Minerals and building

Automatic filling of spodumene big bags

Quarry Minerals and building

Semi-automatic big bag unloading

Cement and plastering Minerals and building

Semi-automated big bag filling for the construction materials industry

Minerals and building

Automated Big Bag Unloading and Conveying

Cement and plastering Minerals and building

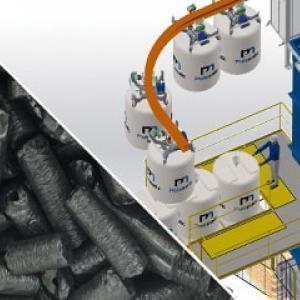

Double deconditioning station and pneumatic dense phase cement transfer

Cement and plastering Minerals and building

Discharging station for bulk bags of ferric sulphates

Quarry Minerals and building

Process for the manufacture of plasterboard

Cement and plastering Minerals and building

Discharge and dosing for mixer feeding

Quarry Minerals and building

Big bag filling station with suspended weighing

Quarry Minerals and building

Big bag filling station Flowmatic 07

Cement and plastering Minerals and building

FlowMatic® 03 big bag filling line with barite

Quarry Minerals and building

Discharge of big bags of plaster for re-packaging into containers

Cement and plastering Minerals and building

Automatic opening and emptying of bags of plaster, cement and starch

Cement and plastering Minerals and building

Discharge of big bags of cement for truck loading

Cement and plastering Minerals and building

Big bag filling of white minerals, talc and carbonates under a silo

Quarry Minerals and building

Aggregate conveying and storage line

Quarry Minerals and building

Palamatic Process has proven expertise in the treatment, extraction, crushing, grinding, dosing, homogenization or conveying of bulk materials, such as quicklime, silica, alumina and iron oxides. Also, the use of admixtures in the manufacture of concrete makes it possible to attribute certain properties to it, particularly for high-performance concretes (technological innovation). The experience of Palamatic Process engineers and the powerful software packages used make it possible to design and implement these specific production processes. Palamatic Process offers a complete service from the definition of the requirement to the commissioning.

The process steps, for example for the manufacture of cement:

- Raw material extraction

- Grinding and storage of raw materials

- Baking of raw materials

- Storage, crushing and screening

- Packaging and conveying line

The pneumatic conveying of cement with specific equipment allows you to obtain a long service life of the installations by minimizing maintenance as much as possible.