Big bag emptying can be difficult depending on the product handled and the type of big bag used.

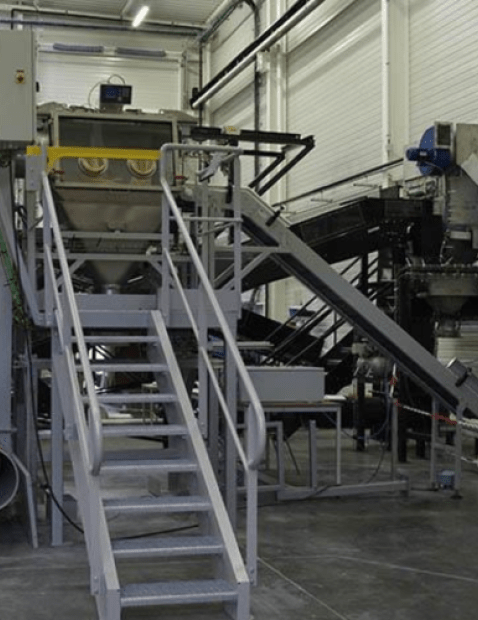

Greasy, cohesive, compacted or hygroscopic products and ingredients require extraction assistance. With our experience of more than 1,000 bulk bag station installations around the world and in a wide variety of sectors, PALAMATIC PROCESS has developed 5 major options to help extract your difficult products.

1. Big bag vibration

The vibration of the big bag is taken into consideration when your materials become compacted. The storage of big bags via stacking can result in significant compaction. Vibrating the depositing plate of the big bag emptying station breaks this solidification and agitates the flow of the material.

The solution, which consists of vibrating the big bag, is not a guaranteed to work on every material, but does offer satisfactory results on crumbly and dry products. For oily or damp products, it will be necessary to opt for a mechanical extraction solution.

2. Big bag massage

The big bag massage is performed by pneumatic or hydraulic cylinders. The big bag massage cylinders are located below and on the sides of the unloading station. The number of jacks installed on the big bag emptying station varies from 2 to 6. The big bag massage jacks always work in pairs. The efficiency of this option is extremely important because of the large strokes of the cylinders. The massage paddles push directly into the the heart of the bulk bag, which assists in breaking up of the solid materials and forces the powders and granules to drain out of the big bag. The Palamatic Process test station offers you the opportunity to come and test these options.

Depending on the products handled, the automatic control system is adjusted to allow a number of different cycles, with adjustable sequence intensity timings, depending on your products.

3. Tension of the cross

Using a big bag handling hanger can promote the material unloading. Based on this observation, Palamatic Process integrates an autonomous tensioning system on the big bag unloading stations located on the bulk bag handling cross. Gas jacks or springs calibrated to the weight of the big bags ensure automatic lifting of your bulk bag as it is emptied. This big bag tension prevents the creation of product retention pockets and breaks product arching that may appear during emptying.

If your require further assistance,

I am at your entire disposal.

Loïc, expert in powders

4. Connection tube under tension

Another viable and even more efficient solution consists in tensioning the big bag via its emptying sleeve.

When the operator has established the big bag discharge spout on the connection tube, a piloted pneumatic cylinder provides continuous tension and creates a “funneling effect” on this sides of the big bag. This extremely efficient option is particularly suitable for bulk bags with internal bag or with internal partitions. As it stretches, the big bag is fully emptied without any retention of product and in a dust-tight manner.

Big bag massage Handling cross Connection tube Big bag cut-out

5. Cutting the bottom of the big bag

Some products are so compacted in their packaging that it is impossible to extract them through the emptying sleeve. The only solution available to you is to cut the bottom of the big bag.

Palamatic Process can integrate puncture blades into the big bag emptying station design, which fully opens the bottom of the bulk bag. This solution is used for extremely compact and poor flowing products for which other extraction options are ineffective.

Palamatic Process has a full test center to see, test and confirm the best option to implement. Accompanied by our powder handling experts, you can design the big bag emptying station in accordance with your handled powders!