The Inflatek valve, also known as an inflatable seal valve, is a reference industrial solution for the precise control of powder and bulk material flow. Designed for industries such as energy, food processing, chemicals, minerals, and construction, it features an inflatable sealing system that ensures optimal tightness and a leak-free closure. Unlike conventional valves, the Inflatek valve guarantees full containment of the processed materials, thereby reducing the risk of contamination and dust emission.

Its robust build and long-lasting performance make it a strategic choice for manufacturers aiming to optimise their processes while meeting safety and environmental standards. This article provides an in-depth overview of the features, advantages, and applications of the Inflatek valve, highlighting essential criteria for successful implementation in your facility.

Pour en savoir plus sur le fonctionnement, vous pouvez consulter cette vidéo explicative :

1. What is an Inflatek valve and how does it work ?

1.1 Definition and Operating Principle

The Inflatek valve is an innovative solution for regulating the flow of powders and bulk solids, designed to offer superior sealing and minimise product loss. Unlike traditional valves, it includes a mobile cap that, when engaged by an inflatable seal, applies even pressure to the flow channel, ensuring a hermetic, leak-free seal.

Its high-performance inflatable seal system removes excessive contact points, reducing mechanical wear and extending service life. This design also offers easier handling and simplified maintenance, ideal for demanding process environments.

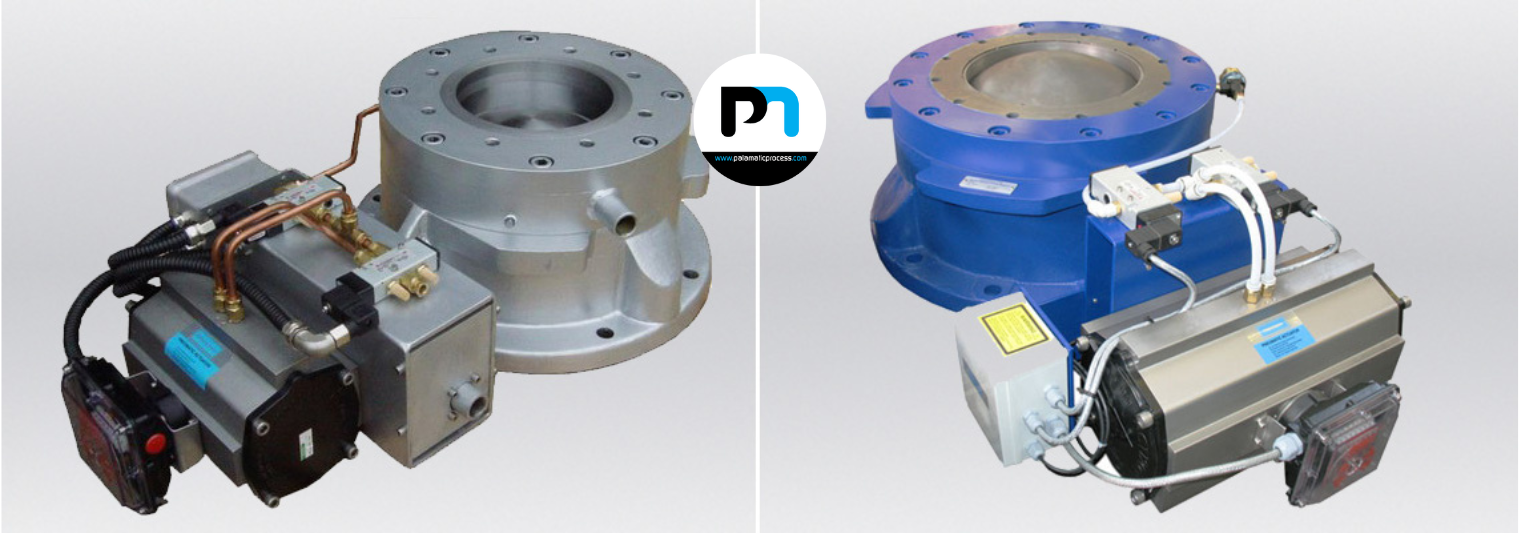

1.2 Key Components of the Inflatek Valve

- Valve body: constructed from stainless steel for excellent resistance to corrosion and abrasion in harsh settings.

- Mobile cap: a crucial part ensuring secure closure and effective product containment.

- Inflatable seal: engineered for precise inflation/deflation to achieve a perfect seal while protecting product integrity.

- Pneumatic actuator: allows for automated, accurate opening and closing, reducing manual intervention and improving reliability.

1.3 Why Choose an Inflatek Valve?

- Outstanding sealing: eliminates leakage for a safe and hygienic process environment.

- Extended durability: robust construction with high-quality materials ensures a long service life.

- Minimal maintenance: quick and easy inflatable seal replacement with no full dismantling required.

- Industrial compatibility: suitable for automated operations and compliant with ATEX and strict safety regulations.

2. What are the advantages of the Inflatek valve ?

2.1 Sealing and Powder Containment

- Eliminates leakage and dust emission, ensuring a safe and clean work area.

- Fully compliant with stringent environmental regulations and certified for ATEX zones.

- Enhances the containment of sensitive or hazardous materials, reducing cross-contamination risks.

2.2 Reliability and Durability

- Manufactured from stainless steel and high-resistance materials to ensure durability against corrosion and abrasion.

- Designed for continuous operation in extreme industrial environments.

- Fitted with a long-lasting inflatable seal that minimises servicing needs and extends product life.

2.3 Versatility and Industrial Adaptability

- Suitable for a broad range of powders, including abrasive, toxic, and hygroscopic substances.

- Applicable in food processing, chemical, pharmaceutical, and mineral sectors—ideal for diverse process needs.

- Compatible with automated production systems, boosting productivity and operational efficiency.

3. Where and how to use an Inflatek valve in your facility ?

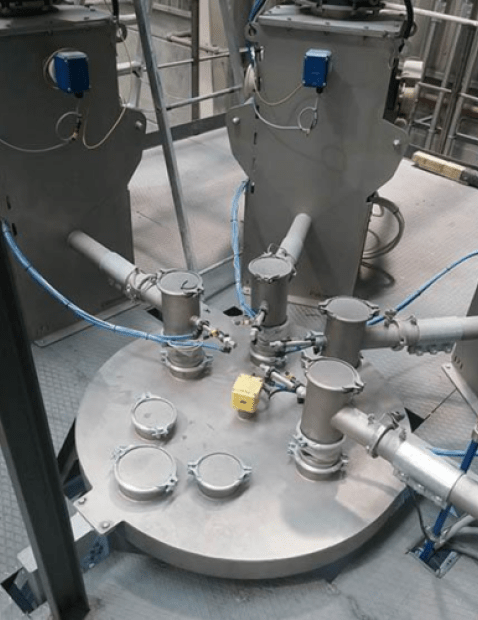

3.1 In Dosing and Weighing Systems

- Integrates into gravimetric and volumetric dosing systems for accurate raw material distribution.

- Maintains consistent dosing accuracy, helping to minimise waste and reduce production costs.

3.2 In Pneumatic and Mechanical Conveying Lines

- Provides precise control of material flow, avoiding blockages and loss of product.

- Compatible with positive and negative pressure systems, perfectly suited for modern automated lines.

3.3 In Bulk Bag Filling and Unloading Systems

- Delivers complete containment during filling and unloading, significantly limiting dust emissions.

- Designed for seamless integration with bulk bag and silo equipment, reducing manual handling.

Do you have a powder dosing or transfer project ?

I’m available to support you with expert advice and a tailored approach.

Guillaume, expert in powder processing systems

4. How to select the right Inflatek valve for your application ?

4.1 Key Technical Criteria

- Required diameter and flow rate based on material properties and system requirements.

- Construction materials selected according to the production environment (e.g., stainless steel for food applications, steel for chemical processes).

- Operating temperature and pressure must align with process specifications for optimal performance.

4.2 Options and Configurations

- Position sensors and automation-ready controls for real-time monitoring and remote operation.

- Manual or pneumatic actuation available, depending on system design and accessibility.

- May be integrated with weighing and dosing systems to ensure precise control and repeatability.

4.3 Compliance with Standards and Regulations

- ATEX certified for use in explosive atmospheres (e.g., combustible dust, chemical industries).

- FDA and CE compliant for applications in the food and pharmaceutical sectors.

- Meets UK and EU environmental regulations, helping to prevent pollution and ensure workplace safety.

The Inflatek valve is a key piece of equipment for ensuring safe and efficient control of powder and bulk material flow. With its high sealing performance, durability, and adaptability, it is a strategic investment for industries looking to optimise production and minimise losses.

5. Frequently Asked Questions (FAQ)

5.1 What is the typical service life of an Inflatek valve?

A well-maintained Inflatek valve can last many years due to its robust design and durable inflatable seal, which reduces wear. The lifespan will vary depending on material quality and usage frequency. Preventive maintenance helps maximise longevity.

5.2 Is the Inflatek valve suitable for all types of powders?

Yes, the Inflatek valve is designed for a wide variety of powders, including:

- Fine powders: such as flour, sugar, talc.

- Abrasive materials: like sand, cement, or metallic oxides.

- Hygroscopic substances: such as salts, acids, or moisture-sensitive chemicals.

- Toxic and explosive powders: with dedicated designs for high-risk applications.

Material and configuration choices depend on the specific characteristics of the powder in question.

5.3 Can the Inflatek valve be used in ATEX zones?

Yes, several Inflatek valve models are ATEX certified (zones 20, 21, 22), suitable for use in explosive atmospheres. These models are built with specialised materials and spark-resistant components to meet strict UK and EU safety regulations.

5.4 How to maintain an Inflatek valve to extend its lifespan?

Routine maintenance is crucial for keeping the Inflatek valve operating at peak performance. Recommendations include:

- Regular inspection of the inflatable seal for early wear signs.

- Frequent cleaning of the mobile cap and product passage to prevent buildup or blockage.

- Monitoring actuators and sensors to ensure proper system response.

- Preventive replacement of worn components to avoid unexpected downtime.

6. Conclusion

The Inflatek valve is the ideal solution to ensure precise dosing and effective sealing in powder-handling operations.

Looking for a solution tailored to your process ? Get in touch with our experts for a personalised consultation!