In many industries, handling octabins and big bags is a strategic challenge. These large containers, often filled with bulk materials, require tailored solutions to ensure effective, safe, and loss-free discharge. Without appropriate equipment, companies face major issues: time loss, operator risks, contamination of raw materials, and inefficient production lines.

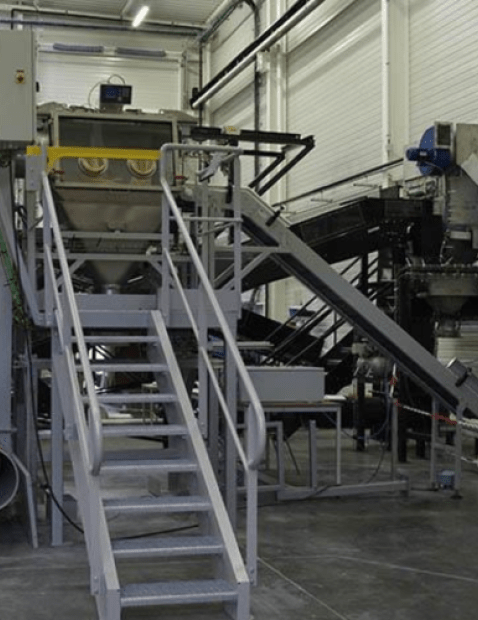

To address these challenges, the OctoFlow®02 — an innovative octabin tipper station — offers advanced automation, improved ergonomics, and enhanced safety. This equipment optimises octabin emptying and ensures a steady production flow. In this article, we will explore how an octabin tipper station works, its benefits, and how the OctoFlow®02 is transforming the discharge of octabins and big bags.

1. What is an octabin tipper station ?

Definition and operation

An octabin tipper station is industrial equipment designed to facilitate the emptying of octabins and big bags — large reinforced cardboard or plastic containers used to store and transport bulk products. The octabin tipper ensures efficient and safe handling by gradually tilting the container to recover its contents evenly.

The main goal of this equipment is to automate and streamline the discharge process while ensuring operator safety. It typically consists of:

- A robust frame to hold the octabin in place,

- A motorised or pneumatic tilting system,

- An integrated de-dusting device to limit particle emissions,

- An ergonomic control unit for precise tipping management,

- An optimised connection for pneumatic or mechanical product transfer.

Why use an octabin tipper?

Using an octabin tipper station offers several major benefits for industries handling bulk materials:

- Reduction of musculoskeletal disorders (MSDs): Manual emptying of octabins and big bags can cause repetitive strain and uncomfortable postures. An automated tipper improves workstation ergonomics.

- Optimised production time: By automating the emptying process, downtime is reduced and production pace is improved.

- Better material management: Controlled tilting allows even distribution of product, minimising loss and facilitating line feed.

- Process safety: Dust containment and stable operation reduce the risk of inhalation and particle emission.

- Adaptability to various packaging types: Whether octabins, big bags or plastic sacks, the station adjusts to industrial requirements.

Which industries use these systems?

Octabin and big bag tipping stations are widely used across multiple industrial sectors:

- Food industry: For handling powdered ingredients (flour, starch, sugar) or granules.

- Chemical and fine chemical industries: Handling bulk chemicals with strict containment and safety standards.

- Pharmaceuticals: Integration into sterile environments where hygiene compliance is critical.

- Plastics industry: Transfer of resins and plastic granules for injection or extrusion processes.

- Construction and minerals: Used for mineral powders, cement or other bulk materials requiring controlled transfer.

Using an octabin tipper station is therefore part of an industrial optimisation approach, reducing physical strain, enhancing productivity and ensuring a safer working environment.

Are you planning to integrate an octabin tipper into your production line?

I am available to advise and support you with your project.

Guillaume, expert in octabin handling

2. Introducing the OctoFlow®02: a high-performance discharge solution

Features and benefits

The OctoFlow®02 is an octabin tipper station designed to meet the needs of industries handling bulk materials. It offers several advanced features:

- Automatic tilting system for efficient and safe discharge.

- Robust stainless steel structure, ideal for demanding environments.

- Dust containment system for a cleaner working area.

- Compatibility with various formats of octabins and big bags, ensuring high flexibility.

- Intuitive interface for precise control of the discharge process.

- Connectivity options for integration with conveyor or suction systems to optimise production flow.

How does the OctoFlow®02 improve octabin handling?

- Increased automation: Reduces manual intervention, limits errors, and improves accuracy.

- Better ergonomics: Reduces physical strain on operators.

- Optimised production flow: Increases throughput thanks to faster, smoother discharge.

- Compliance with safety standards: Designed to meet food and chemical industry requirements.

- Adaptability: Compatible with automated lifting and handling systems.

Comparison: manual tipper vs. OctoFlow®02

| Criteria | Manual tipper | OctoFlow®02 |

|---|---|---|

| Automation | Low | High |

| Ergonomics | Strenuous | Optimised |

| Discharge time | Long | Reduced |

| Discharge precision | Variable | Consistent |

| Safety | Risk of load drop | Controlled |

The OctoFlow®02 stands out thanks to its enhanced performance, ease of use, and its ability to improve working conditions.

Conclusion

The OctoFlow®02 is an effective and ergonomic solution for discharging octabins and big bags across a range of industrial sectors. By reducing physical strain, increasing productivity and ensuring a safe working environment, this octabin tipper station is a strategic choice for companies looking to optimise their material handling processes.

Would you like to learn more or integrate the OctoFlow®02 into your production line? Contact our experts for a tailored consultation!