Description

PalSack®04 - DHW Doser |

|

Easy clean bag filling station

Containment, precision, high cleanability, gross weighing

The PalSack®04 ECD bag conditioner is specially designed for manufacturers who wish to change products frequently with cleaning phases.

-

Rate3

-

Dosage accuracy5

-

Hygiene5

PalSack®04-J-C-Gross

PalSack®04-J-P-Gross

This bag filler incorporates the very latest easy clean dispenser from Palamatic Process, offering easy dismantling, without tools, of all the equipment components. Access to the dosing screw, the agitator arm and the buffer hopper is easy and ergonomically designed. Supporting guide rails allow for opening of the dosing equipment without any lifting requirements by the operator.

The design of the powder feeder provides high dosing accuracy as well as safe and fast packaging of the programmed material quantities. The touch controls interface provides access to the main commands for recipe changes, product changes, machine calibration, bagging, etc. Complete reports on batch packaging remain stored in the control automaton.

Possible configurations of the PalSack®04 model:

| Ref. | Possible equipment | Functions | Advantages | |

|---|---|---|---|---|

| Configuration | P | Tray support | Tension of the bag during filling | Hygienic, height adjustment for adaptability to multi-format bags |

| C | Motorized roller conveyor | Holding and evacuation of the bag during filling | Ergonomics, increased speed |

Our PalSack®04 packaging machine can be configured by modulating the possible basic equipment: support plate or evacuation conveyor.

Possible reference example: PalSack®04-J-C-Gross

Advantages of the equipment:

- Simple, efficient, multi-format: changing recipes from the integrated touch screen.

- Ease of use: recipe management at the control desk; simplified adjustment of the different formats

- Dosing device adapted to your products: endless screw or vibrating doser (optional)

- High dosing accuracy +/-1%

- Productivity: up to 100 bags/hr

Available versions:

Motorized belt conveyors can be offered in order to improve packaging capacity and ensure optimal ergonomics for the operator.

In the basic version, the entire structure of the packaging machine is made of 304 or 316L stainless steel in order to meet food grade equipment standards.

Weighing:

The control of the dosing equipment is provided by load cells installed on the structure for gross weighing, or gain-in-weight (GIW) operation. The dosing unit is controlled by the load cells, managing low and high speeds, as well as the drop tail. Accuracy is optimized by installing a pneumatic closing valve. All of the technologies implemented, as well as the automatic regulation, can provide precise material dosing of less than 5 grams.

The PalSack®04 Easy Clean Design represents a scalable and modular packaging machine to meet the demands of your customers in terms of hygiene, precision, speed, container types, etc.

Equipment advantages

- Compliant with current food industry standards, all stainless steel

- Easy cleaning: quick dismantling, CIP option, foam cannon, etc.

- Easy dismantling, without tools

- Optimized design and ergonomics according to your layout plan

Media

View our equipment in videos

Sack filling station - Bagging station with integrated screw feeder

Bagging station for filling all types of bags from 5 to 50 kg equipped with an Easy Clean dosing unit. Packaging line for washing detergents and detergent products.

View our equipment in photos

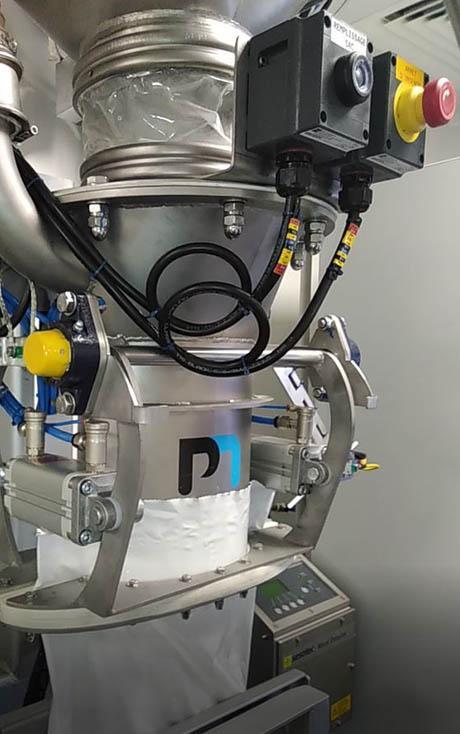

Easy clean dispenser

The easy clean screw feeder, offering easy dismantling, without tools, of all the equipment components.

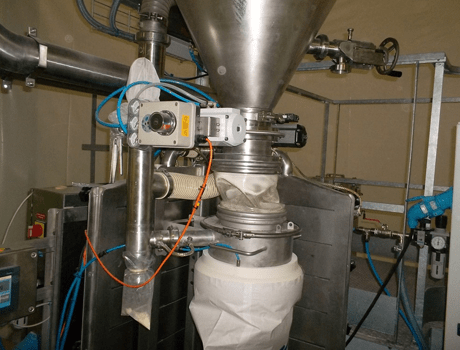

Internal view of the screw feeder

The feeder shaft is easily accessible for thorough cleaning.

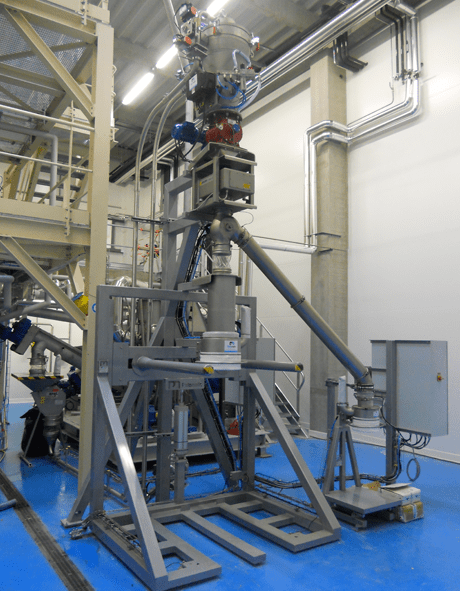

Bag filling skid

The station is fed by an EasyClean dosing unit and can be moved thanks to the handling tubes.

Powder bag sealing machine

The bag packaging line is equipped with a sealing system to ensure the containment of the packaged powder.

High dosing accuracy

Easy cleaning: quick dismantling

Quick and easy removal of the dosing unit

The installation allows the removal of the dosing unit for easy cleaning.

Dosing spiral on EasyClean dosing unit

Supporting guide rails allow for opening of the dosing equipment

Weighing system on filling line

Industrial weighing system on bulk pigment filling line.

Bag filling line with belt conveyor

Conveyor and packaging line for flakes with sealing machine for bag closing.

Bag filling

This bag filler incorporates the very latest easy clean dispenser from Palamatic Process, offering easy dismantling, without tools, of all the equipment components.

Commercial weighing on bag filling stations

The bag filling machine is equipped with a weighing system that allows the gross weighing of the container.

Sealing on the top of the bag after filling

Impulse bag sealer for sealing the bag after the packaging phase.

Feeding of the filling head

The bagging machine is fed with flakes via a butterfly valve installed on the buffer hopper.

Easy dismantling, without tools

The agitator, which ensures consistent and precise volumetric dosing, is also integrated in the removal rail system.

Bag packing with weight control

Conveying and packaging process of flakes in the petrochemical sector.

Packaging station for bags and big bags

The operator positions the bag between the inflatable seal and the clamping ring. By using a pneumatic control, he enables the inflation of the seal which is connected in a sealed way.

Filling station for bags fed by pneumatic transfer

The pneumatic vacuum conveying cyclones feed mixed filling stations: bags and big bags.

Automatic bagging machine

The upstream dosing device fills the bag. The volumes are balanced by the double envelope filling tube.

Bagging station for food powders

Bagging of animal meal on an industrial production line.

Bagging of food powder

Sugar bag packaging line equipped with a conveyor belt.

Baking line

Grinding unit for pure powdered sugar with bag packaging.

PalSack®04 - Filling station for sacks

Equipment:

- FlowMatic® 03 - Big bag filling station

- Clamping ring

- PalSack® - Bag filling station

- Airlock rotary valve

- Magnetic detector

- Pal'touch industrial automation

Internal view of the feeding system

Agitator of the dosing device

Complete line for bag packaging

The hygienic design enables quick disassembly of the dosing unit for easy cleaning.

Opening of the Easy Clean feeder

The opening is guaranteed by the integration of rails and rollers on the flanges of the dispenser.

Easy dismantling, without tools

Compliant with current food industry standards, all stainless steel.

Easy dismantling, without tools

Supporting guide rails for opening of the dosing equipment without any lifting requirements by the operator.

Features

Option for vacuum packaging:

Some food products or powders require packaging under vacuum or inert gas. A specific welding module with gas injection (nitrogen or other) is available. This controlled-atmosphere packaging module is also equipped with a vacuum pump to remove the air before injecting the gas and sealing the bag.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Preparation of spice mixtures

Processed products: spices - Preparation of spice mixtures - The objective is a spice blending line with cleanability of the equipment and recipe flexibility.Food and Animal Feed

Laundry powder packaging

Processed powders: detergents and washing powders - Laundry powder packing - Packaging of powdered finished products in 20, 25 and 30 kg bags.Chemical