Description

Deaeration, densification, shaping

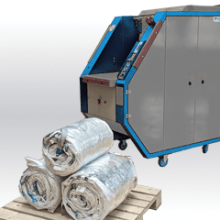

The FormR® bulk bag forming and densifying stand is suitable for a wide range of powders, including food-grade materials.

An innovative and efficient solution for handling big bags containing powders, it enables bulk bags to be shaped, densified and degassed to obtain a cubic format perfectly adapted to pallet dimensions, thus facilitating storage, transport and handling.

When filling powders into bulk bags, the density of your products is often increased due to the aeration of the product during the transfer, dropping and mixing phases...

This machine is designed to work on pre-conditioned big bags, integrating filter fabrics on the top of the bulk bag.

The bulk bag shaping cabinet is the dedicated solution for deaerating your bulk bags by forcing the compression of the packaged powder. Bulk bags processed by the hydraulic compression chamber come out with a regulated dimension, facilitating storage of your products and guaranteeing their stability on pallets. Big bags freed of excess air offer a clean, professional presentation, in addition to all the safety benefits.

Controlling the density of your powder is essential to obtaining a correctly packaged bulk bag. The FormR® deaeration station is the unique solution for densifying your powders and adapting your big bags to pallet dimensions.

Equipment advantages

- Bulk bag stability

- Powder density control

- Accurate and corrected bulk bag dimensions

- Bulk bag stability

- Two or three bulk bags can be stacked on top of each other

Features

Technical specification

- Lifting and positioning system: the machine is fitted with a lifting and positioning system to lift and place pre-packed super sacks in the operating area.

This system enables the bulk bag to be placed directly into the machine enclosure by forklift truck.

- Densification platform: a sturdy, stable densification platform supports the bulk bag during the densification process.

- Movable top with suction system: the machine top moves vertically to compress the bulk bag and ensure optimum densification. The roof is fitted with a suction system to evacuate air trapped inside the bulk bag during compression, facilitating degassing and powder densification.

- Movable forming panels: the machine's panels are positioned around the bulk bag to create a perfect form to the exact dimensions of the pallet. This ensures greater stability during storage and transport of the bulk bags.

- Enclosure and centralized dust removal: the FormR® cage is fully enclosed and connected to the centralized dust removal system, guaranteeing a clean and safe working environment for operators.

- Vibration system: an adjustable vibration system is installed under the densification platform to help reorganize the powder particles inside the FIBC and expel trapped air through the filter fabrics at the top of the bulk bag.

- User interface: the machine features a user-friendly interface enabling operators to control densification parameters such as vibration intensity and duration, as well as the movement of the top and moving sides.

- Safety door with detection: once the bulk bag has been positioned, the operator closes the safety door. The compression cycle can only be triggered once this door is closed, ensuring optimum safety for operators.

- Maintenance: the machine is designed for easy maintenance and cleaning, with accessible and replaceable parts.