Description

Bulk bag filling - Containment, densification and bulk weighing

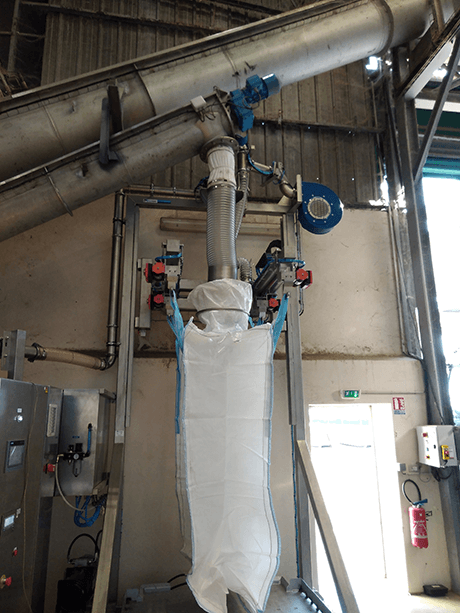

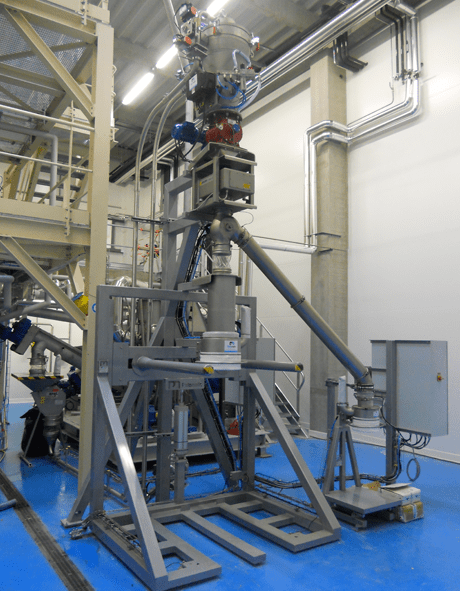

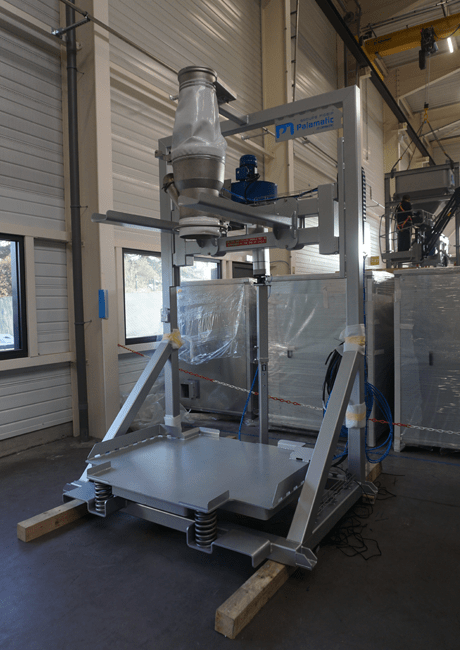

The FlowMatic® 03 filling system's structure is easily adjustable to condition bulk bags of various sizes. The tensioning cylinder and pre-forming fan help maintain the shape of the bulk bag for optimal filling. The vibrating table ensures the deaeration of low-density products and densification of various materials.

The FlowMatic® 03 filling system has a filling rate ranging from 10 to 20 bulk bags per hour.

-

Automation3

-

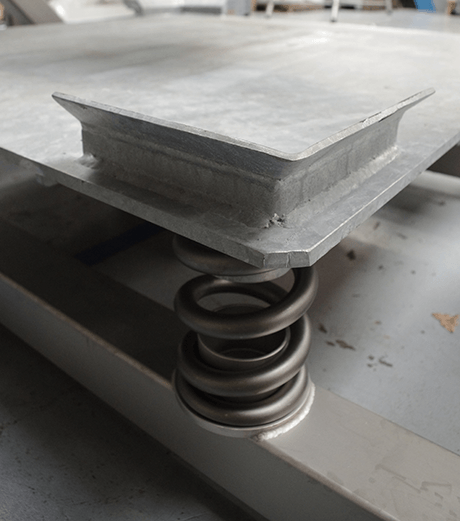

Rate3

-

Overall dimensions5

Operating mode :

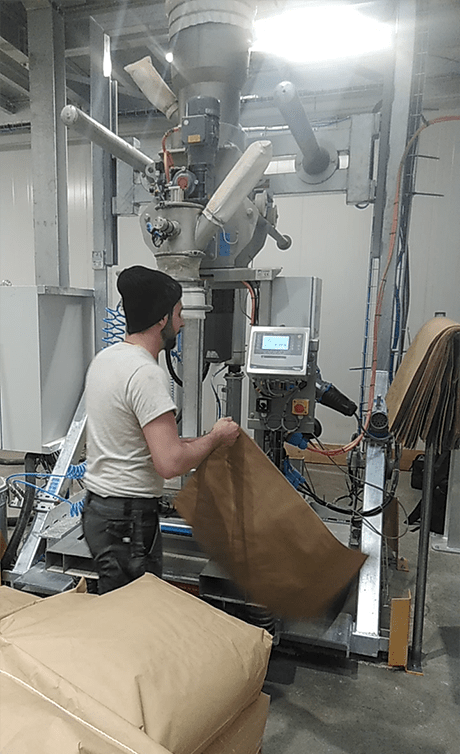

1. Installation of the bulk bag on the packaging station

2. The bulk bag spout is fixed to the filling head by means of an inflatable seal which ensures dust containment during operation.

3. Tensioning of the bulk bag with the pneumatic cylinder

4. The pre-forming fan inflates and shapes the bulk bag (FIBC)

5. Inflating fan is deactivated and another fan used for reverse jet filtration of the bulk bag is switched on

6. Bulk bag filling starts with high flow rate capability

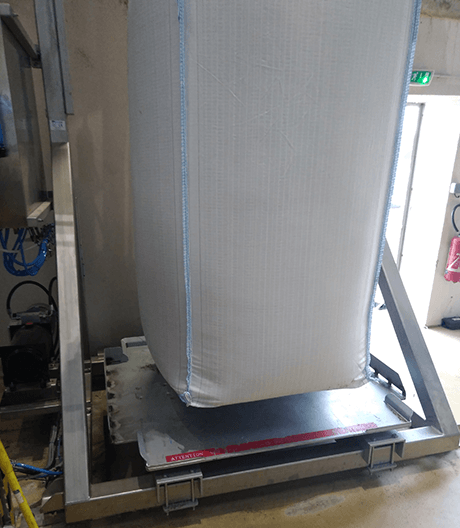

7. Bulk bag comes to rest on its pallet and the vibrating table ensures stability of the bulk bag during filling and handling

8. Vibrating table further ensures densification of material with intermittent operation throughout the filling process

9. Load cells allow for weight management via a low speed switch to adjust the flow rate for final dosing

10. End of the filling process, the forks lower and the seal deflates. The bulk bag is ready to be unloaded

11. Removal of the bulk bag can commence by forklift, pallet truck or by the bulk bag straps

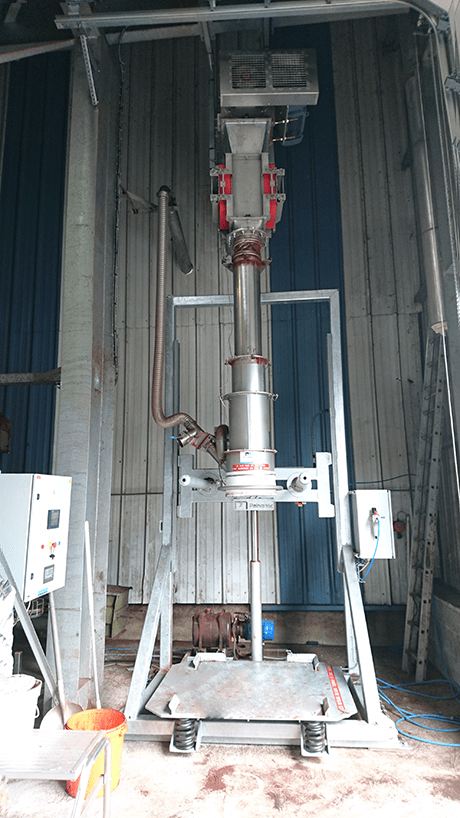

The FlowMatic® 03 bulk bag filling station incorporates all the necessary options for an efficient filling and dust containment operation. These features include the inflatable containment seal, bulk bag hanging deck with pneumatic cylinder height adjustment, bulk bag shaping fan, bulk bag weighing system (dosing), optional commercial weighing and vibrating densification table. The adjustable structure enables the conditioning of bulk bags of various heights and dimensions. The filling head is designed with a double casing to relieve back pressure during filling as well as containment of dust emissions into the atmosphere. The tension cylinder and the fan allow the bulk bag to be pre-formed for optimal filling. Finally, the vibrating table also ensures that the handling of the packed bulk bag is safe by avoiding the risk of tipping.

The FlowMatic®03 bulk bag filling station has a filling rate ranging from 10 to 20 bulk bags per hour.

Equipment advantages

- Dosing and weighing capabilities for commercial operations

- Fan and tension cylinder pre-form and shape the bulk bag to maximize filling

- Vibrating table for the densification of bulk material and stability of the FIBC / bulk bag

- U-shaped forks to remove the bulk bag by its support straps with a forklift

Media

View our equipment in videos

Bulk bag filling unit - FlowMatic®03

Big bag filling system - Flowmatic 03

Containment, densification and gross weighing

The FlowMatic® 03 filling station is easily adjustable to pack big bags of different heights. The tension cylinder, fan and vibrating table ensure that the big bag is optimally shaped. The vibrating table ensures the deaeration of low-density bulk materials.

Bulk bag filling range

View our equipment in photos

FlowMatic® 03 filling bulk bag - Palamatic Process

Flowmatic 03® is a bulk bag filling solution suitable for a wide variety of business sectors.

Big bag filling Flowmatic® 03

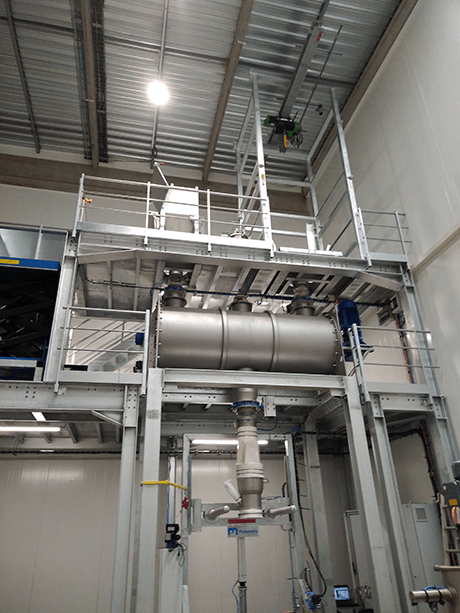

Complete process line for the preparation and management of premixes.

Super sack filling Flowmatic 03

Pictured: A turnkey process line integrating super sack filling stations for the preparation and management of premixed recipes.

Big bag filling station under screw conveyor

The filling station is fitted with a weighing system to enable commercial transactions of the processed powders.

Big bag filling station under screw conveyor

The filling station is fitted with a weighing system to enable commercial transactions of the processed powders.

Bulk bag filling on packaging line

The super sack filler has an integrated mechanical roller conveyor that automates and increases the production rate of the packaging line.

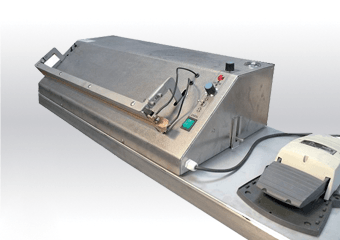

Inflatable seal on bulk bag filling station

The inflatable seal provides a dust tight connection to the spout inlet on the bulk bag. The filling head of the bulk bag packing structure is designed as a double jacketed tube allowing the material to air volume balancing as well as the capture and filtration of dust particules.

Bulk bag loading for a powder handling application

The vibrating table provides material densification for optimal filling and stability of the bulk bag.

Dual bulk bag and sack filling station

Installed at the outlet of a mixer, the material filling station combines the packing of super sacks and open mouth sacks.

The bulk bags are filled with a FlowMatic 03 station equipped with: inflatable seal for a dust tight connection, pneumatic tension cylinder and a vibrating table for the densification of powders and granules during the packing process.

Animal feed industry project for bulk bag filling operation

A complete industrial production line for the manufacture of additives in the animal nutrition industry.

Animal feed application bulk bag filling

Process for the manufacture of additives for the animal nutrition sector, dog and cat food.

Drum and bulk bag filling station

Animal flour packing station on an industrial production line.

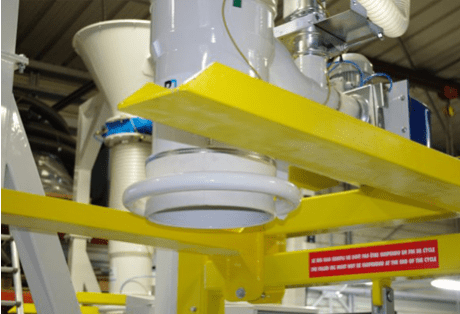

Pneumatic conveying on a big bag filling station

Integrated pneumatic conveying on a big bag filling station. It is used to convey the bulk materials or powders without deterioration.

Powder handling bulk bag filler

FlowMatic® 03 filling line of barite in big bags.

Sugar handling

Powdered sugar packaging line in big bag.

Bulk bag filling for the building and minerals industry

The repacking of prepared powders from a storage silo for the production of plaster.

Plow mixer feeding a bulk bag filling station

This three tiered turnkey installation involves a bulk bag unloader and bag dump station, which both fill a plow mixer. Once the mixing is finished the powder blend discharges into a bulk bag filling station.

Dust-tight bulk bag charger

Spice preparation line for the food industry.

Filling head

Double jacket big bag filling head with inflatable seal and clamping ring.

Ergonomic design for access to the spout inlet of the bulk bag

An operator access platform provides safe and ergonomic access to the big bag filling spout.

Bulk bag in manufacturing production line

Industrial production line with filling station for big bags of sugar.

Screw conveyor feeding a bulk bag filling station

A process system involving the fine milling, transfer and bulk bag filling of seaweed powder for the food industry.

Pal'Touch control cabinet for bulk bag filling application

Pal'Touch industrial automation: The control cabinet is integrated into our Flowmatic 03 bulk bag filling station.

Palamatic Process industrial automation

A Pal'Touch control panel automatically manages the dosing and weighing systems integrated into the bulk bag filling station. This features make it possible to conduct commercial transactions of the packed bulk solids.

Suspended big bag on filling station

Bulk solids mixing and conditioning line.

Building industry bulk bag filling application

The entire structure is adjustable to handle big bags of different heights.

Feed hopper on bulk bag filling station

The bulk bag filling station is fed upstream by feed hopper and vibrating screener.

Big bag filler FlowMatic®03

This big bag filling system is fitted with a roller conveyor.

FIBC filling station

Integrated on the back of the FIBC bulk solids loading station is a pneumatic jack that helps adjust the tension of the FIBC during the filling cycle.

Vibratory table

The vibrating table integrated into the filling station for big bags with calcium carbonate enable the raw bulk material to be deaerated and ensures the stability of the big bag.

Filling head

Big bag filling head on mobile salt conditioning station.

Big bag filler on industrial production line

Integrated equipment:

- FlowMatic® 03 - Big bag filling station

- Clamping ring

- PalSack® - Sack filling station

- Drop through rotary airlock valve

- Magnetic detector

- Industrial automation

Industrial big bag filling station

Big bags are packed with ingredients for the food industry.

Big bag filler in the food feed industry

The big bag filling station is positioned on handling wheels.

FlowMatic® 03 - Minerals and building industry

The big bag is filled with barite from quarries.

Big bag filler for fishmeal powder

Dosing, mixing and packing line for animal feed in big bags.

Features

Technical specification

| Rate | 10 to 20 bulk bags/h. |

|---|---|

| Capacity | 2 tons/bulk bag |

| Manufacturing materials | Mild steel, 304L stainless steel |

| Installed power | 3 kW |

| Compressed air consumption | 0.9 Nm³/h. |

| Dust removal rate | 176 CFM |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 0.2kW

Operating pressure: 6 bar

Digital input: 6

Digital output: 6

Accuracy of the weighing chain: ± 1 lb.

Maximum size of bulk bags: 61"L x 61"W x 94.5"H

U-shaped forks: allow the removal of the bulk bag by the handles (optional)

Equipment integrated into the FlowMatic®03 model:

- Round hooking forks of the bulk bag: offers easier sliding of the bulk bag handles.

- U-shaped forks for attaching the bulk bag handles: allow the bulk bag to be evacuated directly through the handles using a forklift truck (no pallet is used).

- Support Structure: The structure is adjustable via a pneumatic cylinder to accommodate varying sizes of bulk bags. Width adjustment: the spacing of the hanging forks is adjustable to optimize the filling operation and provides greater stability of the FIBC when resting on a pallet.

- Inflatable seal: change “tight” to “dust-tight”

- Filling head: The filling head is a double-jacketed design to allow for air to material volume balancing. The air exhaust can be connected to a dust filtration system for a clean working atmosphere.

- Tension cylinder: the pneumatic cylinder is attached to the suspension forks and allows for height adjustment for operator ergonomics, accommodation of varying bulk bag sizes and optimal shape of the bulk bag during the filling cycle. The bulk bag is filled without risk of air pockets or folds, and can be safely handled without risk of tipping over.

- Pre-inflation fan: integrated on the filling head, the fan provides two functions. First, it helps shape the bulk bag for optimal filling (no folds or creases). Second, an integrated by-pass valve helps balance the air volume while material if filling the bulk bag. Any fine particulates, or dust, are vented through the double jacketed filling tube during the filling phase. This vent can be connected to a dust collection system for a clean and safe work environment.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Paint formulation

Processed powder: paint powder (polyester resin + fillers + additives + pigments) - Paint formulation - A manual container emptying station feeds a big bag filling system. The container unloading...Chemical

Animal flour loading

Powders processed: feather flour, animal flour - Animal flour loading - Palamatic Process has set up a bulk bag packaging station with vibration and automatic releaseof the bulk bag.Food and Animal Feed

Mineral packing

Processed powder: barite - Mineral conditioning - FlowMatic® 03: sealed filling of big bags with barite with automatic weighing.Minerals and building

Process for food supplements

Processed products: Vitamin A, Vitamin E, Metasmart dry - Process for food supplements - Bulk Bag filling station with integrated weighing and vibrating densification table.Food and Animal Feed

Premix compound packing

Treated powder: premix compound - Premix compound packing - Our customer, a specialist in PVC compounds and polymer composite materials, required the packing of its finished product - polymer...Chemical

Packaging process optimization

Processed powder : fish meal - Big bags packaging - Output of 50 big bags/hFood and Animal Feed

Filling bulk bags with fly ash

Processed powder: fly ash - Filling of big bags for building materials via gravity discharge from a silo.Minerals and building

Bulk bag filling equipment for semi-automatic process in the fish food industry

Processed powders: meat meal and bone meal - Semi-automatic bulk bag filling stations - The installation consists in loading big bags under mixers without emitting dust.Food and Animal Feed

Reconditioning of nickel hydroxide in battery manufacture

Processed powders: nickel hydroxide, nickel sulphate and sodium hydroxide Recovery of nickel hydroxide cake for packaging in bulk bagsEnergy

Receive your quotation in 3 clicks!