Description

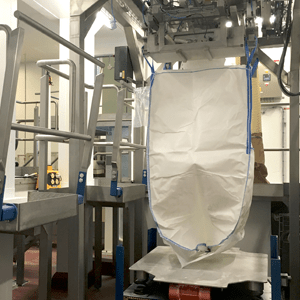

Bulk bag filler - AUTOMATIC PACKAGING IN GROSS WEIGHING

The FlowMatic® 04 bulk bag filling equipment is the complete solution for automatic conditioning of bulk bags in gross weighing operations. This FlowMatic® 04 model is designed for continuous use at high flow rates of 20 - 40 bulk bags/hour.

The FlowMatic®04 FIBC filling automation equipment incorporates an inflatable dust containment seal and a height-adjustable structure. The adjustable structure makes it possible to package bulk bags of various dimensions and according to the characteristics of the bulk materials.

-

Automation5

-

Rate3

-

Overall dimensions3

Operating procedure:

1. Automatic feeding of empty pallets via a belt conveyor

2. Installation of the bulk bag on the filling station

3. The bulk bag spout is connected to the inflatable seal for dust containment and stability

4. Tensioning and height adjustment of the bulk bag by pneumatic cylinder

5. Inflation of the bulk bag for preforming and efficient filling

6. Switch from the inflation system to the dust collection exhaust

7. High rate filling commences

8. Bulk Bag is gradually lowered onto the pallet. Bottom of the bulk bag is formed to promote stability for handling

9. Vibration table works intermittently during filling operation to densify and deaerate the material.

10. Gross weight management with a low speed switch to adjust the final dosing stage

11. End of filling: lowering of the filling head, deflation of the seal and automatic removal of the bulk bag loops

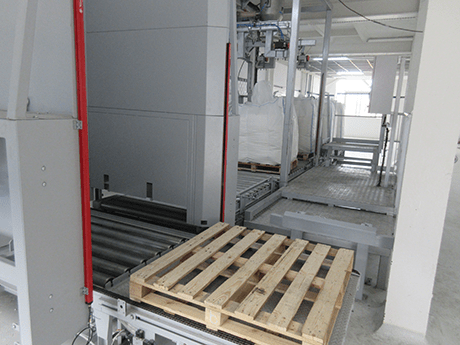

12. Automatic removal of the bulk bag to the storage area by belt conveyor

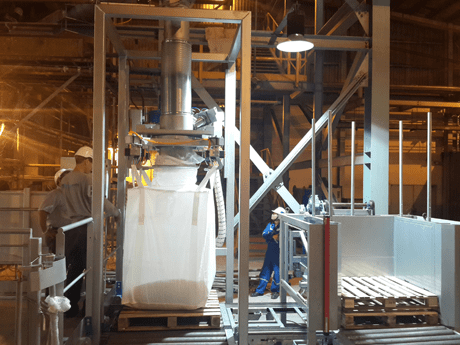

Automatic gross weighing and super sack loader

The complete solution for automatic conditioning of bulk bags, FIBCs, super sacks, jumbo bags and bulk bags in gross weighing operations. This model is designed for continuous use at high flow rates of 20 - 40 bulk bags/hour.

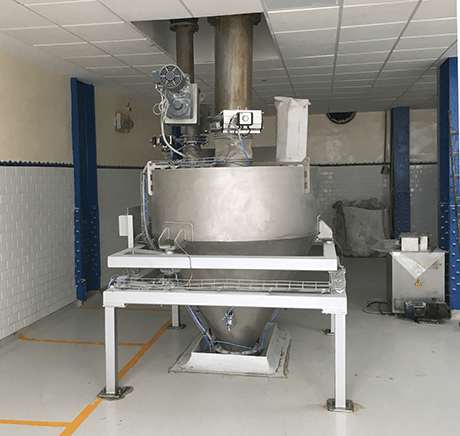

The automated bulk bag filling FlowMatic 04 integrates all the necessary options for bulk bag packaging with minimum operator intervention: inflatable seal, bulk bag hanging deck with pneumatic cylinder height adjustment, bulk bag pre-forming fan, weighing and dosing of bulk bags, optional commercial weighing load cells, vibrating densification table, pallet unstacker, belt conveyor, etc.

Equipment advantages

- Conveyor and buffer storage to achieve high rates

- Automatic dosing and weighing

- Automatic removal of bulk bag loops

- Pallet unstacker with a capacity of 15 multi-format pallets

Media

View our equipment in videos

Big bag filling station - Flowmatic® 04

3D big bag filling system - Flowmatic 04

Bulk bag filling range

Big bag filling system FlowMatic 04

Big bag filler - Flowmatic® 04

View our equipment in photos

Big bag packing

Loading of tobacco dust in big bag.

Automatic conditioning with gross weighing

FlowMatic® 04: automatic packing line of urea in big bags: dosing, packaging and conveying.

Industrial production line for big bags filling

Belt conveyor on a packing line for big bags of sugar.

Packaging station for big bags filling

Automatic big bag filling line for white sugar packing.

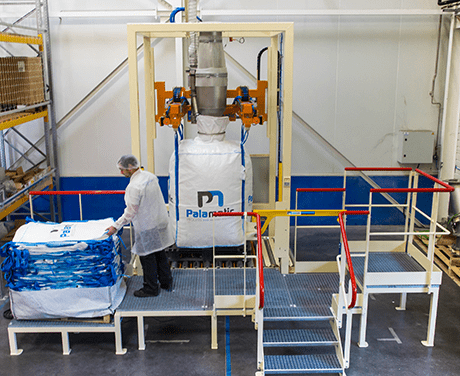

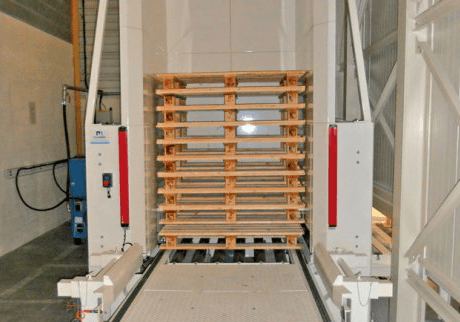

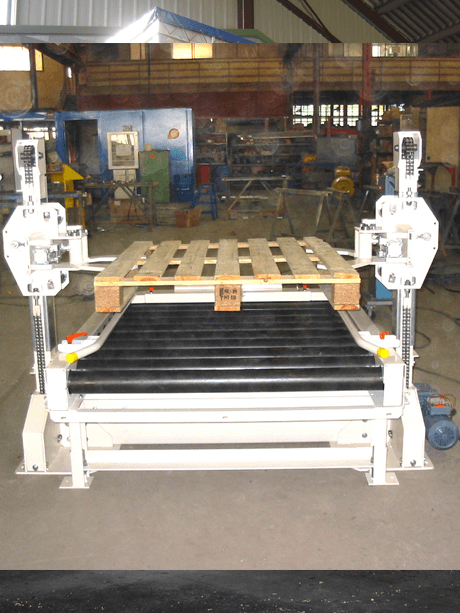

Pallet unstacker

The pallet unstacker is used to automatize the big bag filling station.

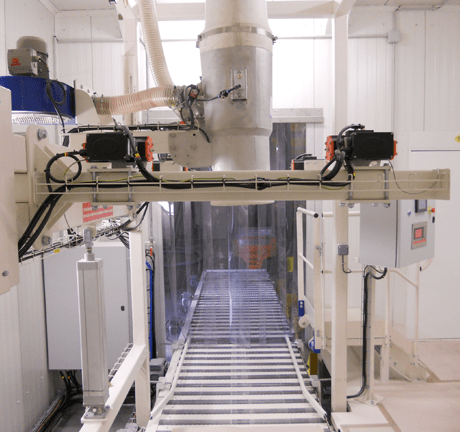

Big bag removal roller conveyor on fibc filling station

Starch discharge in trucks for automatic packing of big bags in the Atex zone.

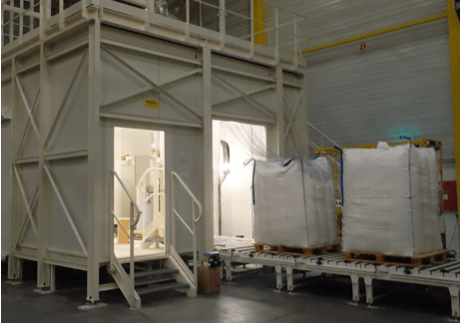

Bulk bag filling system Palamatic process

Hygienic big bag packing station for the preparation of infant milk powder.

Output fibc automatic line after filling system

Packing station for handling food starch.

Big bag filling FlowMatic® 04

FlowMatic® 04: automatic filling line for urea and fertilizer in big bags: dosing, packaging and conveying.

Contained big bag filling system

Cabin for FIBC flowMatic® 04 unloading unit.

Bulk bag raw material applications feeding hopper

Palamatic Process has developed a high speed big bag packing line with maximum hygiene. The purpose of the process is to condition the bulk material, which is fed from the truck to the buffer hopper, in big bags.

Automatic line processing big bag filling

The big bags of sugar are moved by means of a roller conveyor.

Conveyor on bulk bag charger

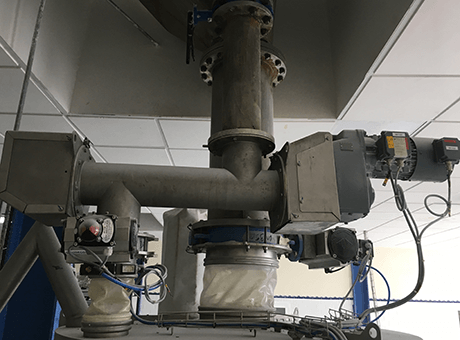

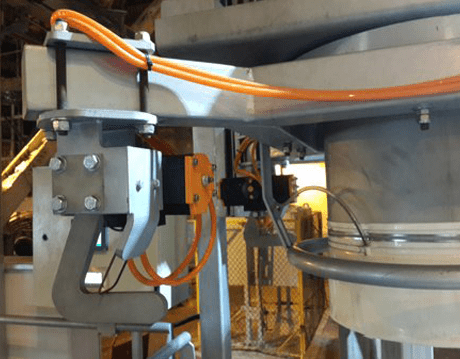

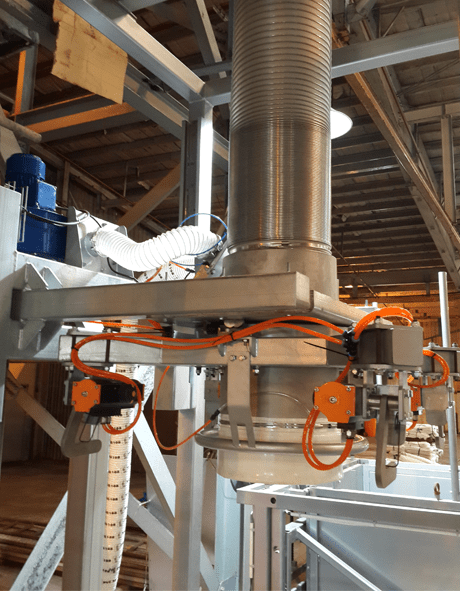

The big bag is attached to the structure by means of automatic pneumatic hooks that hold the big bag when it is filled and automatically release the big bag after filling.

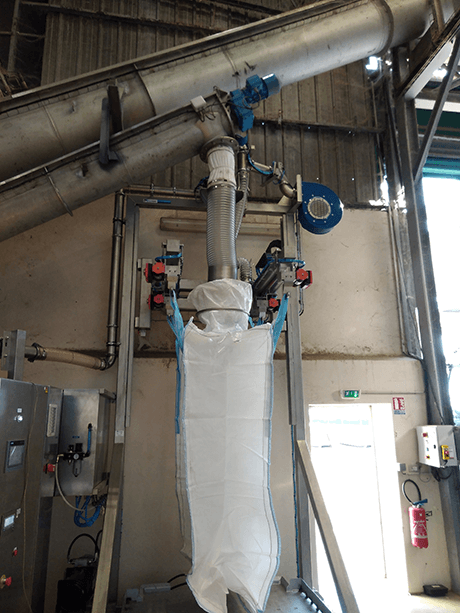

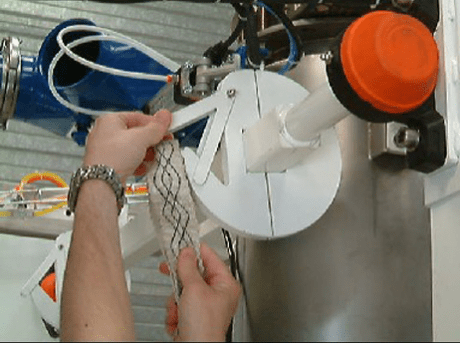

Filling head on FlowMatic® 04

The FlowMatic® 04 big bag filling system integrates all the options necessary for conditioning with a minimum of human intervention.

Bulk bag packing line

The automatic removal of the big bag to the storage area is carried out via a roller conveyor.

High rate and ergonomic big bag filling station

The FlowMatic® 04 filling machine is designed for continuous use at high flow rates.

Bulk bag filler

The big bag is pre-inflated to facilitate filling.

Big bag filler

The big bags of sugar are automatically packed and are weighed gross.

Bulk bag conditioner under screw conveyor

The mechanical conveying screw feeds the big bag filling station.

Big bag filling with sugar

Industrial line for powder and big bag handling.

Bulk materials handling

Spice conditioning line in big bags with open mouth.

Automated line for big bag filling

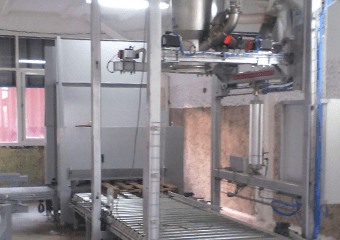

The empty pallet supply is automatic.

Bulk bag contained filling

The operator platform facilitates access to the upper part of the filling machine to close the big bag filling spout.

Big bag filling with control cabinet

Automation of the Pal'Touch® line for the packing of sugar in big bags.

Bulk bag filling line

Industrial production line for filling big bags with sugar.

Big bag filling on pallet

The depalletiser is used to automate the big bag conditioning line.

Speed monitoring big bag filling

The filling speed of the powder in the big bag is controlled.

Big bag filling automatic process line

Filling of big bags with seeds through a feeding hopper.

Positioning of the big bag on the station

The big bag is placed on the forks by the operator and the cuff is placed on the filling head of the sugar conditioning station.

Bagging machine

The removal of the full big bag to the storage area is automatic.

Process hopper

The industrial storage hopper supplies the big bag filling station with iron sulphate.

Big bag filling production line

Bulk material storage solutions in Palamatic Process big bag: Pal'Pack®.

Big bag filling under screw conveyor

Automatic packing line for FlowMatic® 04 big bags for seed conditioning.

Big bag filling raw materials handling Palamatic Process

Automatic packaging line for FlowMatic® 04 urea big bags: dosing, packaging and conveying of fertilizers.

Filling head FlowMatic® 04

Rotating head allows an ergonomic positioning of the big bag on the big bag filling station.

FlowMatic® 04 - Big bag packing

Packing of tobacco dust in big bags.

Big bag sewing after filling

Automatized big bag conditioning line with automatic removal of the big bag to the storage area.

Bulk bag filling

Feeding hopper on big bag conditioner.

Automatic process line - Bulk bag filling

Dosage and weighing of the big bag conditioner: automation and ergonomics of the workstation.

Pallet unstacker

The stacked pallets are stored in the warehouse and then feed one by one the big bag filling station via a motorized conveyor.

Pallet unstacker

The pallet unstacker is used to automate the big bag filling station.

Big bag packing bulk solid

The rotating head on the big bag filling station improves the ergonomics of the workstation.

Automatic release

The automatic release of the handles of the big bag facilitates ergonomics and improves the filling rate.

Filling head

Rotating head on big bags filling station on compounding line for the chemical industry.

Cocoa powder big bag filling

The extraction of cocoa powder from the buffer hopper for transferring it to an existing big bag packaging station.

The conveying is carried out by an aeromechanical conveyor.

Big bag filling system in the food industry

The cocoa powder is conveyed from the buffer hopper to the big bag conditioner via a mechanical conveyor. The mass flow rate is 2,500 kg/h. for bulk materials with a density of 0.65 kg/l.

Big bag filling system FlowMatic® 04

Big bag filling station with rotating head to facilitate loading and unloading of the big bag.

Big bag conveyor - FlowMatic® 04

This installation allows the end product to be extracted from the existing silo through a conveying screw (without an intermediate level to limit Atex risks as much as possible) in order to convey it to the big bag filling station.

Big bag packing - FlowMatic® 04

To meet the requirements of this customer, Palamatic Process has designed a high flow continuous big bag filling model, called FlowMatic® 04, with throughput rates up to 40 big bags per hour.

Rotating head

The filling head is designed with a double jacket to ensure volume balancing and is connected to the dust collection system to avoid any dust emission into the atmosphere. Finally, the rotating system of the hooking head makes it easier to attach the handles of the big bag, reducing the operator's operations and maximizing the ergonomics of his station.

Loading corn seeds

Automatic big bag packing line for corn seeds FlowMatic® 04.

Corn seed packaging line in big bags

The big bag packaging line is equipped with a buffer hopper and a roller conveyor to facilitate the handling of big bags.

Conveyor for pallets handling

Feeding the conveyor line with empty pallets to distribute the pallets one by one.

Process line for big bag loading

Big bag charger located at the outlet of a vacuum-pumped pneumatic transfer cyclofilter.

Features

Technical specification

| Rate | 20 to 40 bulk bags/h. |

|---|---|

| Capacity | 2 tons/bulk bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 8.7 kW |

| Compressed air consumption | 6.8 Nm³/h. |

| Dust removal rate | 300 m³/h. |

Finishes touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 1,1 kW

Operating pressure: 6 bar

Input 4-20 mA: 1

Digital input: 14

Digital output: 13

Accuracy of the weighing chain: ± 500 grams

Maximum dimensions of big bags: 1,200 (l) x 1,200 (L) x 2,400 (H) mm

U-shaped forks: allow the removal of the big bag by the loops (optional)

Equipment integrated into the FlowMatic® 04 model:

- Support structure: the structure is manually adjustable in height to fit all types of super sacks

- Automatic removal of bulk bags: four articulated hooks are installed on the reception deck of the bulk bag. The pneumatic cylinder, operated by the automaton, controls the tilting of the hook at the end of the dosing process.

- Inflatable seal: the inflatable seal ensures a tight connection between the filling head and the FIBC during the filling operation.

- Filling head: the filling head is designed in a double casing for volume balancing. The pressure is displaced through the degassing line which can be connected to the dedusting network.

- Tension cylinder: the pneumatic cylinder is located on the deck of the suspension forks. This allows the automated connection of bulk bag handles via height adjustment. This cylinder also allows conformity to varying bulk bag dimensions and aids in the optimal shape of the bulk bag via tensioning during the conditioning phase. The bulk bag is efficiently filled without any risk of air pockets, and can be handled safely without risk of tipping over.

- Pre-inflation fan: the fan ensures the shaping of the FIBC equipped with an internal bag to facilitate material loading. A by-pass valve makes it possible to degas the fines that are captured by the double-cased tube during the conditioning phase.

- Vibrating table: the densification table makes it possible to deaerate difficult products and ensures the optimal filling of big bags. The vibrating table is equipped with two vibrating motors with adjustable intensity

- Pallet unstacker: the unstacker implements, via a motorized roller conveyor, the supply of handling pallets to the packaging station. The pallet size supported by the unstacker is adaptable.

- Roller conveyor: a series of motorized roller conveyors aid in the transfer of empty pallets to the bulk bag packaging station. They are equipped with positioning sensors to ensure a buffer storage of bulk bags at the outlet of the station

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Fertilizers - Urea

Processed powder: urea - Fertilizers - Urea - Company based in Vietnam, leader in the production of fertilizing products.Chemical

Sugar packing

Processed powder: white sugar - Sugar packing - The FlowMatic© 04 bulk bag filling station allows dust-tight packaging of all types of powders, limits dust emissions and automates the removal of the...Food and Animal Feed

Seed conditioning

Processed powder: treated maize seeds - Seed conditioning - This Multinational, an actor on the world seed market, wants a facility located in Brazil for the automatic packaging of corn seeds in big...Chemical

Loading of ingredients for the production of beverage

Processed materials: citric acid, potassium sorbate, sodium benzoate... - Loading of ingredients for the production of beverage - This installation concerns a new production line in a new building of...Food and Animal Feed

Refined sugar conveying

Processed material: refined sugar - Refined sugar conveying - On-site installation of repackaging equipment for the transfer of sugar stored in shipping containers with an inner liner to a bulk bag...Food and Animal Feed

Automated big bag filling system

Treated powder: spodumene - Big bag filling for lithium battery production - Automated solution with minimal operator intervention.Minerals and building

Production of polyethylene flakes

Processed powder: polyethylene - Production of low-density polyethylene - Company in the petrochemical industry: Installation of 2 bulk bag packaging lines.Chemical

Railcar unloading

Processed powders: tapioca starch, potato starch, corn starch - Unloading of railcars - Line for powder repackagingFood and Animal Feed

Your quotation in 3 clicks!