Description

Vacuum pneumatic conveying systems - Powder conveying:

Material transfer without damage - Suitable for difficult products

Throughput rates from 5 to 10,000 liters/hr

Carbon, 304L and 316L stainless steel construction

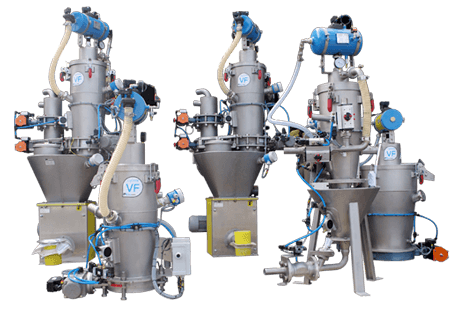

Our VFLOW® range

Dense phase pneumatic vacuum transfer allows the product to be conveyed in a continuous and confined manner without causing material attrition. Particularly adapted to products with poor flow characteristics, integrated pneumatic vibrating flow aids allow for improve material flow of your powders or bulk solids. The cyclone collection can be installed in your production process with the possibility of increased capacities. The pneumatic conveying of powder and granules can be adapted to include multiple product feed points, e.g., bulk bag unloaders, bag dump stations, etc.

Palamatic Process has a range of five cyclone receiver models for pneumatic transfer of powders and granules. Coupled with weighing systems, they allow the weight-controlled introduction of raw materials into your manufacturing process

Gentle material transfer for friable and abrasive products

Palamatic Process offers, within the VFLOW product line, five models of vacuum conveying cyclones for dense phase pneumatic transfer. Our dense phase line is suitable for abrasive materials to prevent damage to conveying lines, as well as preventing attrition for friable powders and granules (sugar, salt, sodium bicarb, etc.). When integrated with weighing systems, these systems can be used with metering equipment (feeders, rotary airlock valves, etc.) for a controlled introduction of raw materials into your manufacturing process.

The new generation of powder pumps, developed by the Palamatic Process design office, provides gentle vacuum conveying which prevents material degradation and the creation of additional dust within your powder handling production process. Particularly suited for difficult materials (poor flow, friability, abrasiveness or explosive), the cyclone collection is easily installed in your process, with extension options to suit your production requirements. Some options include hygienic vacuum conveying equipment, clean in place conveying, and line purge vacuum systems. The conveying system can be designed with multiple feed points and/or destinations in your process. Our pneumatic conveying systems can also be designed to provide material feed into a pressurized reactor vessel without the need for an additional air supply.

3 main functions:

1. Vacuum conveying

2. Dosing of the conveyed product

3. Weighing/Metering

-

Rate3

-

Fragile material5

-

Abrasive material4

Integrated equipment:

- Receiver Body

- Hinged Access Cover

- DN65 Inlet material valve

- DN250 Outlet material valve

- Unclogging tank

- Unclogging nozzle

- DN65 valve for venting

- DN65 vacuum valve

- High level probe

- Spring clips for cover

- Vacuum hose

- Pneumatic equipment plate

- Pneumatic vibrator

Customized vacuum conveying

Conveying systems designed to fit almost any process application

The Palamatic Process engineering office designs custom pneumatic conveying equipment in collaboration with our clients, based on the specifications and requirements of their industrial process.

Based on 30+ years of technical experience, our design office can offer specific solutions for your pneumatic conveying applications including the specific requirements of your manufacturing needs. After meeting with your team, Palamatic Process can define the material conveying solution according to your powder handling specifications.

Equipment advantages

- System flexiblity

- Line purge

- Clean In Place

- Hygienic design

- Loading of reactors under pressure

- Easy implementation

- Suitable for materials with poor flow characteristics

- No material degradation

- Abrasive material conveying

Media

View our equipment in videos

Pneumatic vacuum conveying systems - Powders Pumps - PALAMATIC PROCESS

Range of vacuum pneumatic conveying systems

Range VFlow® Palamatic Process

Mobil unit - Suction tube for drum and sack discharging

Mobile station for discharging bags with suction pipe.

Skid for reactors feeding by doses - PALAMATIC PROCESS

Transfert pneumatique - Cyclone d'aspiration - Palamatic Process

View our equipment in photos

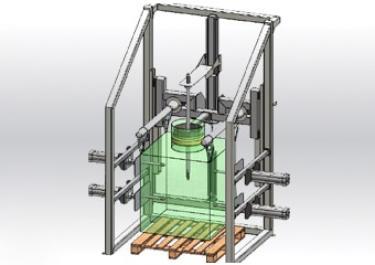

VFlow® pneumatic transfer system

Powder transfer possible via a Palamatic process cyclone receiver.

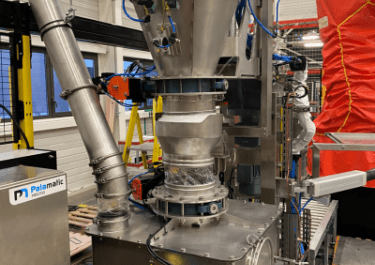

VFlow® Palamatic Process

Pictured: Our VF01 model.

One of five possible cyclone receiver sizes to handle various conveying rates.

VFlow® Palamatic Process

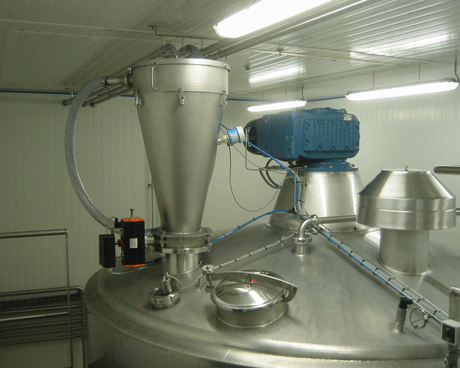

Vacuum conveying solution for dry materials

Cyclone receiver at the end of a pneumatic conveying line to separate the air from the transferred material.

Pneumatic conveying solutions

Vacuum pump installed after the cyclone-filter receiver.

Pneumatic conveying for bulk solids

The VFlow® range provides pneumatic conveying with 95% efficiency for all your powders, granules, flakes and bulk dry materials.

Pneumatic conveying for bulk powders

Vacuum pneumatic conveying line integrated onto a bulk bag filling station.

Pneumatic conveying by vacuum transfer technology

Dense phase vacuum conveying system for the transfer of roasted peanuts in the snack industry.

Pneumatic conveying system for calcium carbonate

Continuous conveying of bulk materials for the production of cosmetics in the fine chemical industry.

Conveying system for bulk solids

The custom-made VFlow® system allows for continuous dilute phase vacuum conveying in your manufacturing process while containing dust. The VFlow® range can be designed to handle friable materials and avoid deterioration of your required particle size.

Vacuum pneumatic conveying system for powder process palamatic

Conveying of coating gelatin for capsules.

Industrial powder handling

At the starting point, the powder is vacuumed from its initial package and stored in a drying tank. The operation is carried out via a dense phase vacuumed pneumatic conveying system VFlow® 01.

Pneumatic conveying for the chemical industry

Conveying and discharging raw materials while promoting a healthy work atmosphere free of dust pollution while avoiding loss of bulk materials.

Dense phase vacuum conveying

Pneumatic conveying provides multiple functions which can help minimize the need for installing additional process equipment.

The VFlow® range of collection cyclones

Bulk material is conveyed by means of a vacuum pump that pulls material into a cyclone receiver (cyclo-filter).

Mobile station for a pneumatic conveying system

Mobile unit for the transfer and dosing of seeds out of 50 lbs. bags.

Mobile pneumatic conveying station - Suction cane for bags and drums

Mobile skid for the pneumatic transfer and dosing of seeds in the food industry.

Pneumatic conveying system for powders

Industrial process for conveying and feeding salt and sugar into a dissolution tank for liquid mixing and drying via an atomization tower.

Skid for dosing and pneumatic conveying

Mobile dosing skid for seed handling and conveying.

Dense phase pneumatic conveyor

Pneumatic conveying by vacuum for industrial powders and bulk solids.

Vacuum pneumatic conveying bulk materials handling

Vacuum pneumatic conveying for industrial production lines involving raw ingredients and bulk materials handling.

Dense phase vacuum pneumatic conveying

Pneumatic vacuum conveying of powders and bulk materials.

VFlow®04 cyclone unit

Cyclone receiver for vacuum pneumatic conveying with integrated rotary airlock valve.

Container discharging with pneumatic conveying system

Integrated equipment :

- Dense phase vacuum conveying system - Detached filter

- Dense phase vacuum conveying system VFlow® 05

- Steel/Stainless steel container

- Container discharging - IbcFlow®01

Pneumatic conveying VFlow®05

Grinding unit for the production of icing sugar and incorporation of starch-type anti-foaming agents.

Pneumatic conveying

The Palamatic Process vacuum conveying system can handle multiple raw material input points. Furthermore, with integrated load cells the conveying system can be used for the controlled introduction of powders by weight.

Dense phase pneumatic conveying

Process powders for the food industry: cocoa, hazelnut, vanilla.

Pneumatic conveying system for silo loading

Turnkey installation for the assembly and commissioning of bulk bag and bag dump station equipment. The industrial process handled various powders and bulk solids to be pneumatically conveyed to a buffer hopper for the loading of a reactor vessel.

Cyclone receiver on silo

Industrial production line for the filling and loading of silos with powders and dry materials.

Liquid formulation line conveying cyclone

2 conveying cyclones feed a reactor: the dosing accuracy must be ensured using the weighing system equipping these cyclones and the reactor weighing system.

Vacuum pneumatic conveyor

Pneumatic conveying for bulk handling equipment and powder processing.

Conveying line for liquid formulation process

This industrial application involved two pneumatic conveying lines feeding two reactor vessels, transferring from industrial storage containers.

Cyclone receiver for liquid formulation line

Two cyclo-filters for feeding reactors with the dosing accuracy provided by load cells. The integrated weighing system on the cyclones allowed for material dosing by weight into the reactors.

Vacuum conveying for filling of reactor

Dense phase vacuum pneumatic conveying system with integrated load cells. The weighing system allows the operator to convey and prepare the next batch of material in automated and hidden time.

Pneumatic vacuum conveying - Dense phase

Multiple material raw inputs for transfer and discharge downstream. Continuous conveying without product loss.

Pneumatic conveying for reactor feeding

Reactor feed airlock for nitrogen gassing.

Conditioning line on pneumatic conveyingg

Integrated equipment:

- Vacuum pneumatic conveying dense phase VFlow® 03

- Ploughshare & blade mixer

- Vibratory screener on pneumatic conveying line

- Big bag filling system - FlowMatic® 02

Plow mixer with pneumatic conveying system

The weighted cyclone is installed on the top floor to free up production space covered by clean zone requirements on the lower floor level.

Plow and blade mixer with pneumatic conveying system

Cyclone receiver at the end of a pneumatic conveying line to dose powders into the mixing system.

Vacuum pneumatic conveying on packaging line

Skid with vacuum pneumatic conveying, discontinuous paddle mixer and drum filling system.

Bag dump station feeding pneumatic conveying line

Food industry manufacturer for yougurt and other dairy based products. The transfer of sugar and enzymes conducted by the VFLOW® 04 pneumatic conveying system.

Pneumatic conveying with screw feeder

Pneumatic conveying of detergent powder with screw feeder for accurate dosing of powder by weight.

Preparation tank feeding

Powder feeding of preparation tanks from big bags and sacks.

Tank feeding - Chemical materials

The process consists of a big bag feeding system (gravity conveyor), three bulk bag discharging stations.

Cyclofilter separator

Supply of the weighed dissolution tank by cyclone separator. The sugar is introduced continuously using a rotary airlock valve.

A cyclofilter is installed on the ground to capture the fines and reintroduce them directly into the conveying piping.

Pneumatic conveying industrial equipment

Integrated equipment :

- VFlow® 02 Pneumatic conveying equipment

- Screw conveyor

- Manual slide valve

- Flexible fitting

VFlow® 02 pneumatic conveying by dense phase vacuum

Pneumatic conveying of kaolin clay for feeding into two atomization towers.

VF02 Dense phase pneumatic vacuum conveying

Main objectives:

- Optimize the bulk material flow

- Separation of the material from the conveying air and drop through the rotary airlock valve

Dosing pneumatic line

Installation of a vacuumed pneumatic conveying system for feeding a conical industrial mixer.

Vacuum pneumatic conveying dense phase

Ready-made meal preparation plant: processing of wheat flour and rice flour.

Pneumatic conveyor for mixing feeder

The mixer is fed with the ingredients: cane sugar, cocoa powder, corn starch, cinnamon powder and hazelnut powder.

Pneumatic sugar conveying

Feeding of a filling machine by dense phase pneumatic conveying for brown sugar, cane sugar, white sugar.

Bag dump station with turnkey pneumatic conveying system

Food additives dosing line with clean in place functionality for all of the equipment.

Vacuum pneumatic conveying dense phase

Conveying of coating gelatin for capsules.

Features

Technical specification

| Models | VF01 | VF02 | VF03 | VF04 | VF05 |

|---|---|---|---|---|---|

| Overall dimensions MM / IN | 660mm / 26" | 820mm / 32.25" | 1,070mm / 42" | 1,070mm / 42" | 1,100mm / 43.25" |

| Flow rate in T / HR | 0 to 1 | 1 to 2.5 | 2.5 to 4 | 4 to 6 | 5 to 8 |

| Ø Piping MM / IN | 38mm / 1.5" | 51mm / 2" | 63.5mm / 2.5" | 76mm / 3" | 104mm / 4" |

| Ø Product outlet MM / IN | 200mm / 7.75" | 200mm / 7.75" | 250mm / 9,75" | 300mm / 12" | 300mm / 12" |

Palamatic Process offers the V-Flow® pneumatic vacuum transfer system running on a dense phase conveying principle.

The bulk material is conveyed via a vacuum pump (electric or pneumatic) and transferred to a cyclone (cyclo-filter) with tangential infeed (cylindrical).

The product is pulled through a pneumatic conveyor gearbox installed at the material feed point (no rotary valve) and delivered to the vacuum cyclone that is equipped with small dust filters to separate the air from the product. The vacuum cyclone is equipped with a butterfly valve (other options available according to the process) and a level probe that allows the material discharge at regular intervals.

The rates obtained by the range of powder pumps are between 5 and 10,000 liters per hour with low energy consumption and simple maintenance.

The other advantage of this powder system is the ease of the implementation for the weight control instrumentation.

Load cells can be integrated into the vacuum cyclone, allowing the controlled vacuum and feeding of the conveyed product by specific quantities.

For incorporation of powder into liquids (powder skid), the powder pump solutions offer the following advantages:

- Weighing of the bulk material

- Simple system

- Easy cleaning

- Simple piping that allows for future modifications

The pneumatic conveyor gearbox can also be replaced with a suction cane that is manually handled by an operator.

This type of powder pump is generally associated with weighing by integrating load cells on the hopper and a purge valve for controlling product flow, ensuring management of the material.

On the contrary, the cyclone receiver can be implemented on load cells in order to extract the right amount of product from different points needed in the preparation of the premix.

All these vacuum conveying systems can be mounted directly under sacks unloading stations, big bags unloading units, containers, silos, etc.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Infant milk powder line

Processed bulk solids: milk powder - Infant milk powder line - This subsidiary company from one of the first milk group in the world, devellops a wide range of functionals and nutritionals milk...Food and Animal Feed

Manufacture of coated peanuts

Processed bulk solids: roasted/caramelized peanuts - Manufacture of coated peanuts - This factory develops and markets chocolate based products.Food and Animal Feed

Loading of kneaders

Processed powders: salt, flour, milk powder, sugar, ascorbic acid - Loading of kneaders - Worldwide company specialized in industrial bakery.Food and Animal Feed

Handling of food starch

Processed powders: gluten and starch - Handling of food starch - company specialized in the conditioning of bulk products and raw materials.Food and Animal Feed

Kibbles manufacturing

Powders processed: palatability enhancers, flavours for dog and cat food - Kibbles manufacturing - Company SPF. To cope with its development, the French company SPF, the "petfood" branch of the...Food and Animal Feed

Powdered egg production

Processed powders: salt and sugar - Powdered egg production - This customer is a specialist in egg processing for industrial customers. This manufacturing process requires an aqueous solution that...Food and Animal Feed

Food flavors manufacturing

Processed powder: maltodextrin with a bulk density of 31 lbs/ft³ - Food flavors manufacturing - The customer required an industrial solution to unpack maltodextrin in 40 and 50 lbs. bags and transfer...Food and Animal Feed

Preparation of instant dairy beverage

Processed powders: milk powder and sugar - Preparation of instant dairy drinks - Agribusiness group in the Island of Reunion is a leading supplier of dairy products within their target markets: fresh...Food and Animal Feed

Icing sugar line

Processed powder: starch and granulated sugar - Icing sugar line - French sugar cooperative company - Supply and commissioning of a set of machines for the production of icing sugar and starch to feed...Food and Animal Feed

Ethanol production

Processed powders: fluorinated derivatives: ammonium bifluoride, sodium fluoride, potassium fluoride, magnesia - Ethanol production - This customer is a specialist in the processing of oilseeds for...Chemical

Liquor manufacturing

Processed powders: beet crystal sugar and cane sugar - Liquor manufacturing - French company specialized in the manufacture of spirits and syrups. The syrups are intended for CHR professionals and...Food and Animal Feed

Skid for metallic powder

Processed powders: metallic powder (bulk density 5) - Skid for metallic powder - The powder is vacuumed from its initial packaging and stored in a drying tank.Chemical

Rubber calendering line

Processed powders: 2 references of carbon black (micro pearl) - Rubber calendering line - The facility includes 2 container discharge systems that supply 2 mixing lines with powdered carbon black.Chemical

Blowing agent for PVC flooring

Powder processed: azobul - Blowing agent for PVC flooring - The continuous dosing supply of a PVC powder into a mixing reactor.Chemical

Masterbatch and additives

Processed powders: cobalt, calcium carbonate CaCo3, titanium dioxide TIO2 - Masterbatch and additives - The objective of the industrial installation is to unload raw materials while maintaining a...Chemical

Compounding line

Processed products: plastic granules - Compounding line - Installation of a big bag and Flowbin emptying station containing powdery or granulated powders in a buffer hopper.Chemical

Manufacture of industrial glue

Processed powders: varnish and gelcoat - Manufacture of industrial glue - This process consists of a combined Duopal® DP02 station for emptying sacks and big bags, a pneumatic conveying system and a...Chemical

Hair cream manufacturing line

Processed powders: potassium persulphate and sodium persulphate - Hair cream manufacturing - A major French industrial group manufacturing cosmetics products wanted to install a new production line in...Fine chemical

Gelatin for capsules

Processed materials: pork gelatin, fish gelatin, bovine gelatin, for capsules coating gelatin for capsules - Gelatin for capsules - This company acting in the pharmaceutical sector is one of the world...Fine chemical

Drinking water filtration

Powder processed: activated carbon and lime (with a respective bulk density of 0.5 ton/m³ and 0.6 ton/m³) - Drinking water filtration - The customer requires a pneumatic conveying system, at a rate of...Water and smoke

Instant chocolate powder

Powder processed: chocolate powder - Instant chocolate powder - This company in the agri-food sector produces chocolates, sweets, condiments, seasonings, sugars...Food and Animal Feed

Resin and gel coat manufacturing

Processed powders: maleic anhydride, Epo Kukdo - Resin and gel coat manufacturing - The client is a world leader in the production of structural resins for the building, automotive, water sports and...Chemical

Dosing in a cutter mincer mixer

Processed powder: starch - Dosing in a cutter mincer mixer - The process is designed to feed a shredder in a controlled way. It consists of an EasyFlow® EF big bag deconditioning system, a VFlow®...Food and Animal Feed

Cake mix

Processed powders: modified starch, sodium bicarbonate, fat powder, whipping base, gelatin, milled sugar - Cake mix - Company based in Saudi Arabia that manufactures and distributes dry food materials...Food and Animal Feed

Animal nutrition food supplements

Processed powders: silica, clay, calcium carbonate, lithothamnium - Animal nutrition food supplements - This customer is a producer of specific mixtures of botanical extracts. In order to ensure its...Food and Animal Feed

Cementation of nuclear waste

Processed powders: Cement + filler, lime and calcium nitrate - Cementation of nuclear waste - This process is intended for the cementation of fines and resinsEnergy

Deconditioning of food powders

Processed powders: wheat starch, potato starch, salt, egg white and sugar - Deconditioning of food powders - The customer is a Breton cannery specialized in the manufacture of surimi.Food and Animal Feed

Raw material dosing

Processed powders: milk powder, salt, sugar and additives - Raw material dosing - This project concerns the deconditioning of raw materials in big bags for the feeding of 2 Viennese pastry production...Food and Animal Feed

Powder incorporator feeding system (powder/liquid mixer)

Processed powder: Mallow powder with a bulk density of 0.5 kg/m³. - Powder incorporator feeding system (powder/liquid mixer) - The purpose of the installation is the vacuum conveying of mallow powder...Fine chemical

Manufacturing of engine additives

Treated powder: diatomaceous earth - Manufacture of engine additives - Safe incorporation of powders with nitrogen inerting sluice in a sensitive environment, ATEX gas zone, zero retention.Chemical

Conveying and grinding line

Processed powder: supplemental milk powder - Pneumatic conveying and grinding line - This company was looking to reduce the granulometry of its final product with a homogeneous particle size spectrum.Food and Animal Feed

Recycling of milk powder by micronization

Processed powder: dairy product flakes, PSD 400 to 500 µm - Recycling of milk powder by micronization - The installation consists of the dosing, transfer, grinding and reconditioning of the milled...Food and Animal Feed

Pharmaceutical powder discharging process

Processed material: sodium bicarbonate - Powder processes in pharmaceutical laboratories - Deconditioning of raw materials (sodium bicarbonate for pharmaceutical application) from bulk bagsFine chemical

Manufacture of glass wool

Material handled: sodium nitrate beads - Manufacture of glass wool - The client, a world leader in insulation solutions, required installation of a pneumatic conveying system for the transfer of...Chemical

Tank feeding

Processed powders: Cobalt Carbonate, Cobalt Hydroxide & Cobalt Oxalate - Tank feeding - The purpose of the installation is to feed the material into a preparation tank from bulk bagsEnergy

Shampoo production line

Processed material: wax, parafin - Shampoo manufacturing - Automated loading of tanks (melters) for the preparation of shampoo.Fine chemical

Dry products dosing for dry mixing

Processed powders: whey, sugar, flavorings - Dry products dosing for dry mixing - Preparation line for the manufacture of ice cream with unitary dosage of different ingredients according to the recipe...Food and Animal Feed

Sugar grinding unit

Processed powders: icing sugar from white granulated sugar and starch - Sugar milling unit - The installation consists of feeding the mill with granulated sugar and then packaging the resulting icing...Food and Animal Feed

Insect breeding unit

Processed products: bran, meal, droppings, live insects, dead insects - Insect breeding unit - This workshop is the heart of the insect breeding process.Food and Animal Feed

Entomoculture treatment unit

Treated products: droppings, dead insects, live insects - Treatment unit in the entomoculture - This unit allows the treatment of non-compliant products from the main process.Food and Animal Feed

Grinding and packaging of finished products

Processed products: dried insects - Grinding and packaging of finished products - Workshop for processing and packaging products for the animal nutrition sector.Food and Animal Feed

Spray tower for packaging feed

Processed powders: skim milk powder / whole milk powder. Client in Africa.Food and Animal Feed

Weighing, conveying, dosing and transfer

Products processed: snack cakes (starch, rice flour, oats) - Weighing, conveying, dosing and transfer - Extraction from big bags and sacks to feed a kneading tank.Food and Animal Feed

Production of dried fruits and seeds

Processed powder: dried fruits and seeds - Mixing and packaging - Our customer wanted to implement a new production line in its plant to support its growth.Food and Animal Feed

Loading catalysts

Processed product: alumina balls - Loading catalysts - The client’s objective is loading two 25 meter high gas treatment towers with catalysts.Water and smoke

Confined deconditioning, dosing and transfer of powders

Processed powders: Minerals and additives (such as titanium dioxide) for the manufacture of paints - Emptying of big bags into mobile IBCs with dosing and transfer of the product to a mixer downstream...Chemical

Manufacturing process for sealants

Processed powder : Sodium hypophosphite - Manufacture and installation of a new turnkey process line for the production of coatings and sealants in an ATEX hazardous location.Chemical

Black mass treatment process

Treated powder: black mass - Black mass treatment process - Process to unload the black mass from bulk bags, precisely dose and repulp it with water, without clogging reactions or dust emissions from...Energy

Process for the production of chocolate

Process materials: granulated Sugar, whey, skim milk powder, and various other minor additives - Process for the production of chocolate - Objectives: unloading, transfer, storage and dosing of...Food and Animal Feed

Cardboard box confined packaging station

Cardboard box confined packaging station - Powder dosing line at dryer outlet for cardboard box packaging feed.Energy

Safe preparation of pyrotechnic powders: automated dosing and mixing line

Treated powders: ammonium perchlorate Safe preparation of pyrotechnic powders: automated dosing and mixing lineDefense