Description

Maintaining the product in motion during long periods of storage

The vibrating bin aerators are used to facilitate the flow of materials as powder and granules. They combine a pressurized fluidizing effect with a slight vibration against the wall of the hopper.

Fluidization and vibration

Powder handling solutions: our vibrating bin aerators combine a fluidization effect with 2 to 6 bar pressure with light vibration against your hopper wall.

Operating mode

Compressed air is introduced in the material directly through the silicon lip adhering directly to the internal silo wall. Vibration intensity is set through the service pressure between 2 and 6 bar. With intermittent operation and a maximum 5 seconds jet, air consumption is extremely low.

-

Efficiency5

-

Air consumption4

-

Noise level4

Equipment advantages

- Heavy duty construction

- Self-cleaning

- Anti-abrasive

- Easy to install

- Service pressure from 2 to 6 bar

- Ambient temperature from -40°C to 170°C

- For powders and granules

- FDA approved

Media

View our equipment in photos

Vibrating bin aerators

Vibrating bin aerator on a cocoa packing line with integrated sieving.

Vibrating bin aerators Palamatic Process

Vibrating bin aerators on compounding process line.

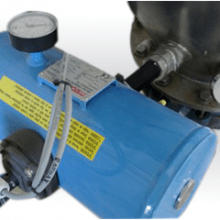

Pneumatic vibrator

Pneumatic vibrator on a glue manufacturing process line.

Vibrating bin aerator bulk handling materials

Vibrating bin aerator on a conveyor and storage line for pharmaceutical powders.

Pneumatic ball vibrator

Pneumatic ball vibrator on a process line for mixing and packaging phytotherapeutic materials.

Pneumatic vibrator

Pneumatic vibrator on storage hopper on a line for mixing natural additives for veterinary use.

Anti-bridging device - Conical bottom

Anti-bridging device with conical bottom on a process line for handling natural food flavours.

Anti-bridging device - Flat bottom

Mechanical unloader with flat bottom on industrial powder handling line.

Features

Technical specification

| Air consumption | |||

|---|---|---|---|

| 2 bar dm³/min bar | 4 bar dm³/min bar | 6 bar dm³/min bar | |

| VB/VBI | 100 | 150 | 250 |

| VBE | 100 | 150 | 250 |

| VBM | 70 | 90 | 250 |

Implementation

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Cementation of nuclear waste

Processed powders: Cement + filler, lime and calcium nitrate - Cementation of nuclear waste - This process is intended for the cementation of fines and resinsEnergy

Powder incorporator feeding system (powder/liquid mixer)

Processed powder: Mallow powder with a bulk density of 0.5 kg/m³. - Powder incorporator feeding system (powder/liquid mixer) - The purpose of the installation is the vacuum conveying of mallow powder...Fine chemical