Description

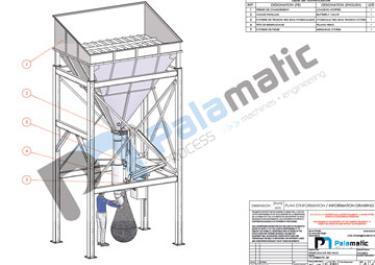

Bulk bag filler FLOWMATIC 08 - PACKAGING LINE FOR HANDLING BULK BAGS WITH ONE LOOP VIA A TELESCOPIC FILLING TUBE

The FlowMatic® 08 bulk bag packaging station allows simple FIBC loading of bulk materials with large tonnage capacity requirements. Efficient and flexible, the FlowMatic 08 is designed to store large quantities of bulk materials specifically for grain and feed, mining, and fertilizer industries.

The FlowMatic® 08 single loop bulk bag packaging station is equipped with the following features: loading hopper, hydraulic tension cylinder, load cells, bulk bag filling head, support structure.

Available options:

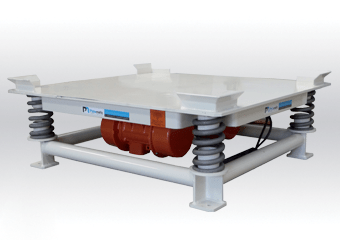

- Pre-inflating bulk bag fan

Palamatic Process has developed a full range of bulk bag, FIBC, super sack, jumbo bag and big bag filling stations to meet the different needs of industries. The FlowMatic®08 represents the efficient and flexible solution for the simple packaging of bulk products, mainly dedicated to mining, grain or agricultural industries.

-

Automation2

-

Rate3

-

Overall dimensions4

Equipment advantages

- Commercial weighing

- Loading from bulk storage hopper

- Fan to ensure the forming of the bulk bag and inner bag

- Bulk bag tension hook and filling mouth

Media

View our equipment in videos

FlowMatic® 08 big bag filling system

Remplissage big bags FlowMatic 08

Big bag filling systems - Packing line for handling big bag 1 handle with manuscopuc loading.

Bulk bag filling range

View our equipment in photos

Big bag filling FlowMatic® 08

This FlowMatic®08 big bag filling station for big bag with one handle with a feeding hopper equipped with a butterfly valve that allows or not its closing.

Bulk bag conditioner FlowMatic® 08

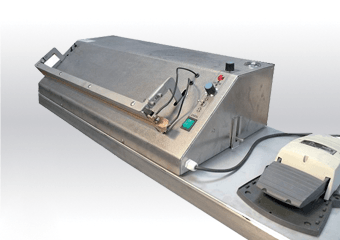

The big bag conditioner is provided with a simple hanging system specially designed for big bags for one handle. An inflatable seal completes the filling head.

Bulk bag filling systems

Big bag filling systems - Packing line for handling big bag with one loop with manuscopic loading.

Bulk bag filling systems with platform

FlowMatic® 08 big bags filling on a big bag conditioning line in the hygienic zone (white zone) of baby food materials.

Palamatic Process - big bag filling

Automatic conditioning line for urea big bags: dosing, conditioning and conveying.

Conveyor on bulk bag charging line

Big bag filling station on a spice reconditioning line from storage containers.

Big bag packing

Automatic big bag filling line for white sugar packing.

Load cells on bulk bag filling line

Hygienic big bag conditioning station for infant milk powder for the preparation of infant milk powder.

Sugar packaging in bulk bag

The sugar is packed in big bags for storage.

Filling head on bulk bag charger

The FlowMatic® big bag filling system integrates all the options necessary for packing with a minimum of human intervention.

One handle big bag filling

The packaging machine is equipped with a simple hanging system specially designed for single-loop big bags. An inflatable seal completes the filling head. The big bag filling station is positioned on load cells for commercial weighing.

Big bag filling hopper loading

The hopper is loaded via a handling machine. The fertilizer is then packaged in big bags with one loop.

Features

Technical specification

| Rate | 40 to 60 bulk bags/h. |

|---|---|

| Capacity | 2 tons/bulk bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 7.8 kW |

| Compressed air consumption | 2.1 Nm³/h. |

| Dust removal rate | 600 m³/h. |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average absorbed power: 0.3kW

Operating pressure: 6 bar

Accuracy of the weighing chain: + or - 500 gr.

Maximum dimensions of big bags Length * Width * Height: 1,300 * 1,300 * 2,400

Equipment integrated into the FlowMatic® 08 model:

- Filling head

- Support structure

- Loading hopper

- Hydraulic tension cylinder

- Load cell

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Seeds

Processed products: Fertilizers and seeds - Seeds - Production and trade of cereals for livestock feed.Chemical

Receive our quotation in 3 clicks!